Cincinnati Centerless Grinders A Legacy of Precision in Manufacturing

Cincinnati, Ohio, has long been a hub of industrial innovation, and at the heart of its manufacturing prowess lies the technology of centerless grinding. This process, which revolutionizes the way materials are shaped and finished, is a specialty of Cincinnati’s factories, forging a legacy of precision engineering that serves industries worldwide.

What is Centerless Grinding?

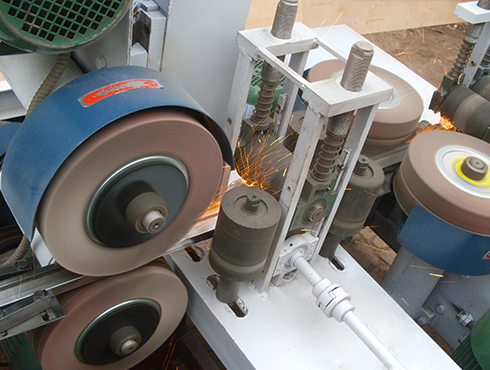

Centerless grinding is a machining process that produces cylindrical parts without the need for supporting them at either end. The workpiece is held in place by a combination of rotating wheels a grinding wheel and a regulation wheel, with a workpiece support blade that guides the part. This setup enables a smoother, more effective grinding operation, resulting in superior surface finishes and dimensional accuracy.

The Cincinnati Advantage

Cincinnati is recognized for its innovative designs and high-quality machinery in the realm of centerless grinders. Cincinnati's commitment to precision engineering is reflected in the various models designed to cater to different production needs, from small-scale operations to large manufacturing enterprises. This adaptability is one of the key reasons Cincinnati centerless grinders have become synonymous with reliability and efficiency.

One of the standout features of Cincinnati’s grinders is their versatility. Industries ranging from aerospace to automotive heavily rely on centerless grinding to create components that meet stringent specifications. The ability to produce high-precision parts at a high throughput makes these machines invaluable on modern production lines. For example, components like shafts, rods, and bushings require uniform diameters and smooth surfaces, attributes that centerless grinding is uniquely suited to achieve.

Manufacturing Processes in Cincinnati

Cincinnati’s factories employ state-of-the-art technology and practices, ensuring that every centerless grinder is manufactured to the highest standards. The production begins with the selection of high-grade materials, followed by advanced machining techniques that include CNC (Computer Numerical Control) operations. This attention to detail is crucial, as even minor imperfections can result in significant defects during the grinding process.

cincinnati centerless grinder factories

In addition to the robust machining processes, Cincinnati’s factories are equipped with quality control systems that rigorously test each grinder before it leaves the facility. This involves checks for accuracy, consistency, and durability, all essential for maintaining the legacy of excellence that Cincinnati has established in the manufacturing sector.

The Role of Innovation

Innovation has always been a cornerstone of Cincinnati’s approach to manufacturing. With the rise of automation and digital technologies, Cincinnati centerless grinder factories have embraced these advancements to enhance productivity and precision. By integrating smart technology into their machines, including real-time monitoring and feedback systems, manufacturers can ensure optimal performance and anticipate maintenance needs before they lead to downtime.

Moreover, the evolution of materials science has allowed Cincinnati to develop grinders that can handle a wider range of materials, from softer metals to hard alloys, expanding the scope of applications for their machines. This adaptability is a significant competitive advantage in a rapidly changing global market.

Training and Support

An often-overlooked aspect of Cincinnati's success is the training and support they provide to their customers. Understanding that advanced machines require skilled operators, Cincinnati invests in comprehensive training programs designed to help staff optimize the use of their centerless grinders. This commitment to customer support underscores the company’s belief that lasting partnerships with manufacturers are built on knowledge transfer and ongoing assistance.

Conclusion

The legacy of Cincinnati centerless grinders is one of precision, reliability, and innovation. From their beginnings in the heart of Ohio to their global presence today, these machines exemplify the high standards of American manufacturing. As industries continue to evolve, the adaptability and technological integration of Cincinnati’s centerless grinders position them at the forefront of manufacturing solutions, ensuring that they will remain a vital component of production for years to come. Whether for small enterprises or large-scale operations, Cincinnati continues to provide the tools that shape the future of manufacturing, embodying the very spirit of industrial excellence.