The Cincinnati 2 Centerless Grinder A Legacy of Precision and Innovation

In the world of industrial machining, few names resonate as profoundly as Cincinnati. Known for its commitment to quality and precision, the Cincinnati 2 Centerless Grinder stands out as an emblem of advanced engineering and manufacturing excellence. The evolution of this remarkable machine encapsulates a significant chapter in the history of grinding technology, playing a crucial role in industries ranging from automotive to aerospace.

A Brief History of Cincinnati Grinders

Cincinnati Machines was founded over a century ago, during a time when American manufacturing was experiencing rapid growth. The company quickly established itself as a pioneer in the field of machine tools. Cincinnati's focus on innovation and customer needs led to the development of various grinding technologies, including the centerless grinder.

Centerless grinding is a method that allows for the efficient production of precision cylindrical parts without the need for them to be held in a chuck or fixture. This technique provides faster production times, flexibility, and less material waste compared to conventional grinding processes. Recognizing the demand for such efficiencies, Cincinnati introduced the 2 Centerless Grinder, which became a vital tool within the manufacturing sector.

Features and Specifications

The Cincinnati 2 Centerless Grinder is engineered to deliver remarkable accuracy and repeatability. One of its hallmark features is its ability to grind parts with tight tolerances, making it ideal for applications requiring high precision. The machine's robust design minimizes vibration, contributing to superior surface finish and dimensional stability.

Equipped with a uniquely designed work rest, the Cincinnati 2 allows operators to easily adjust the position and angle, accommodating various part sizes and shapes

. This adaptability is crucial in a production environment where changes occur frequently, and manufacturers must pivot quickly to meet client needs.Another noteworthy feature is the grinder's drive system, which ensures optimal power transmission to the grinding wheel. This technology allows for effective chip removal, thereby enhancing productivity and reducing downtime during production runs. The machine can accommodate a variety of grinding wheel sizes and types, making it versatile for different applications.

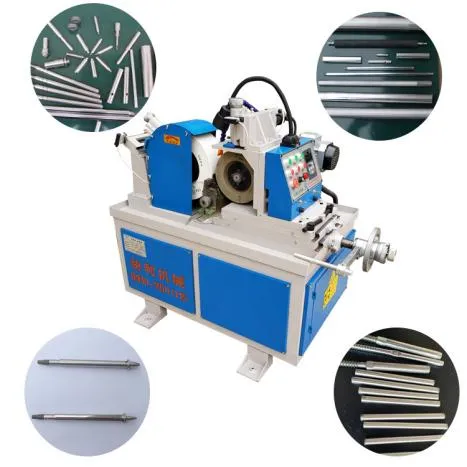

cincinnati 2 centerless grinder factory

Applications and Industries

The Cincinnati 2 Centerless Grinder has found its way into multiple industries thanks to its versatility and reliability. In the automotive sector, for instance, it’s employed to grind components such as shafts, rollers, and gears, contributing significantly to vehicle performance and safety. In aerospace, the precision it offers is paramount, where even the slightest deviation can lead to catastrophic failures.

Moreover, the medical device industry utilizes centerless grinders to produce intricate parts for surgical instruments, prosthetics, and other critical components. The ability to maintain strict tolerances while ensuring high production rates is what makes the Cincinnati 2 an indispensable tool in these applications.

The Future of Grinding Technology

As manufacturing continues to advance, the Cincinnati 2 Centerless Grinder remains relevant by incorporating the latest technological innovations. With the integration of digital controls, operators can now monitor and optimize grinding processes in real-time, improving efficiency and reducing scrap rates. Automation is gradually becoming a part of the equation, with robotic systems assisting in part loading and unloading, further enhancing productivity.

Moreover, sustainability has become a pressing concern in manufacturing. The Cincinnati 2 is designed to minimize waste and energy consumption, aligning with the industry’s move toward greener practices. By adopting efficient grinding techniques, manufacturers can reduce their environmental footprint while maintaining high standards of quality.

Conclusion

The Cincinnati 2 Centerless Grinder not only represents a significant advancement in grinding technology but also embodies the spirit of innovation that has characterized Cincinnati Machines throughout its history. As industries evolve and new challenges arise, the principles of precision and efficiency that the Cincinnati 2 stands for remain essential. Commitment to quality, adaptability, and forward-thinking technologies ensures that this legendary machine will continue to serve as a cornerstone of manufacturing excellence for years to come.

In summary, whether it is the automotive, aerospace, or medical device sector, the Cincinnati 2 Centerless Grinder is a vital asset, enhancing production capabilities and supporting the relentless pursuit of quality in machining. Its legacy is not just defined by its design and capabilities but also by the countless success stories that have emerged from its use in factories around the world.