Precision in Motion The Role of China’s Precision Centerless Grinders

In the ever-evolving landscape of manufacturing, precision machinery plays a pivotal role in ensuring high standards of production quality. Among these machines, centerless grinders have emerged as essential tools in the realm of precision engineering, particularly within China’s growing industrial sector. This article delves into the significance of precision centerless grinders, their operational principles, and their impact on various industries in China.

Understanding Centerless Grinding

Centerless grinding is a machining process that allows for the efficient shaping, finishing, and sizing of workpieces without the need for fixtures or workholding devices. Contrary to conventional grinding methods, this technique involves the placement of the workpiece between two wheels a grinding wheel and a regulating wheel. The grinding wheel is responsible for the material removal, while the regulating wheel controls the workpiece’s rotation and feed rate. The absence of center holes or fixtures in the workpiece allows for continuous machining, which enhances productivity and reduces cycle time.

The Mechanics Behind Precision Centerless Grinders

In China, precision centerless grinders are engineered with high-tech components that optimize performance and precision. They incorporate advanced features such as CNC (Computer Numerical Control) systems, which enable precise control over the grinding parameters. This automation not only enhances the accuracy of the grinding process but also ensures consistent quality across production runs. Additionally, modern centerless grinders are designed for adaptability, allowing manufacturers to switch between different workpieces and materials with minimal downtime.

The use of high-quality grinding wheels and advanced cooling systems further ensures that the grinding process remains stable and efficient. This combination of technology and design enables manufacturers to achieve tolerances as tight as a few microns, making these machines invaluable in industries where precision is paramount.

Applications in Diverse Industries

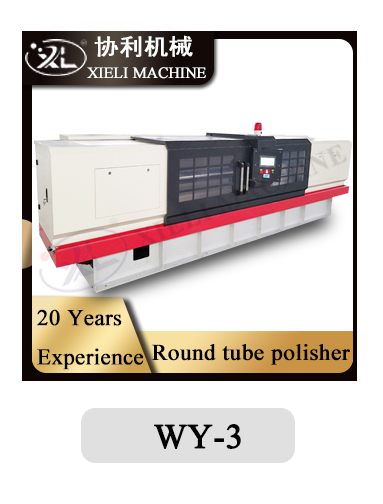

china precision centerless grinder

The applications of precision centerless grinders in China are vast and diverse. They are extensively utilized in the automotive, aerospace, medical, and electronics industries, where the precision of components is critical to performance and safety. For instance, in the automotive sector, centerless grinders are employed to produce engine parts, transmission components, and other critical pieces that require exact dimensions and surface finishes.

In the medical field, precision centerless grinding is essential for manufacturing surgical instruments and implants, where even the slightest deviation in size can lead to product failure. The aerospace industry also relies on these grinders to produce lightweight yet durable components that can withstand extreme conditions. Furthermore, the electronics sector uses centerless grinders to manufacture precision shafts and connectors vital for electronic devices.

The Future of Precision Centerless Grinding in China

As China strengthens its position as a global manufacturing powerhouse, the demand for precision centerless grinders is expected to grow. The country’s commitment to technological advancement and automation will likely drive innovations in grinding technology. With the integration of artificial intelligence and smart manufacturing practices, future centerless grinders may achieve even higher levels of precision and efficiency.

Additionally, as industries increasingly prioritize sustainability, manufacturers are exploring eco-friendly grinding processes that minimize waste and energy consumption. This shift will necessitate further development of precision centerless grinders that accommodate these new standards.

Conclusion

The landscape of manufacturing in China is continuously shaped by advancements in precision machining technologies. Centerless grinders stand at the forefront of this transformation, offering unmatched efficiency and accuracy. Their essential role in industries ranging from automotive to aerospace underscores their importance in the pursuit of excellence in manufacturing. As technology evolves, so will the capabilities of precision centerless grinders, ensuring that China remains a key player on the global manufacturing stage. Through precision and innovation, the future of manufacturing in China looks promising, heralding a new era of efficiency and quality in production.