Centerless Tube Grinding Machines An Overview of Suppliers

In the realm of precision engineering, the demand for high-quality components has never been more critical. One essential process that contributes significantly to the production of precise cylindrical parts is centerless tube grinding. This method provides a streamlined approach to grinding tubes and rods, enabling manufacturers to achieve tight tolerances and superior surface finishes. The rise in demand for these machines has consequently led to a surge in suppliers catering to different industrial needs.

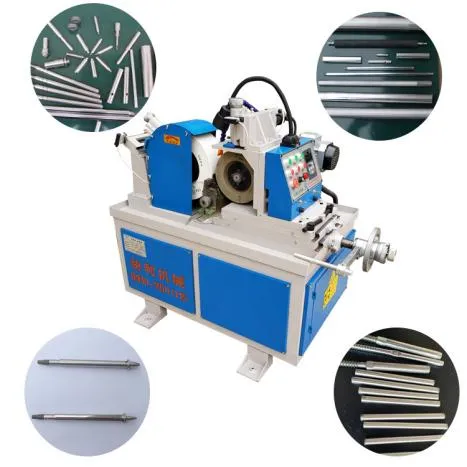

A centerless tube grinding machine operates without the need for a fixture to hold the workpiece. Instead, the tube is held in place through the interaction of the grinding wheel and a lower regulating wheel. This system not only enhances efficiency but also allows for processing longer workpieces with consistent results. The versatility of these machines enables them to grind various materials, making them suitable for industries ranging from automotive to aerospace and beyond.

When searching for a reliable centerless tube grinding machine supplier, several factors come into play. Firstly, the supplier's reputation within the industry is paramount. Established companies often have proven track records and client testimonials that can provide insight into the quality and reliability of their machines. A good supplier will not only offer machinery but also provide invaluable services such as technical support, maintenance, and spare parts availability.

Secondly, the range of products offered by a supplier is crucial. Different manufacturers have varied needs, and a supplier that provides a diverse selection of machines with customizable features can better meet the specific requirements of each client. For instance, some manufacturers may need machines capable of high-volume production, while others may require specialty machines for bespoke applications.

centerless tube grinding machine supplier

Another critical consideration is technology. The grinding machine industry has seen significant advancements in technology, leading to the development of CNC (Computer Numerical Control) centerless grinders. These machines offer unparalleled precision and automation, simplifying the grinding process and minimizing human error. Suppliers that invest in advanced technology and innovation are more likely to provide equipment that meets the rigorous demands of modern manufacturing.

In addition, one cannot overlook the importance of after-sales support and services. A supplier that offers comprehensive assistance, including installation, training, and proactive maintenance plans, adds significant value. With complex machinery, unforeseen challenges may arise, and having a knowledgeable support team can ensure smooth operations and minimize downtime.

Moreover, geographical considerations play a role when selecting a supplier. Local suppliers can often provide quicker service and support, reducing lead times for parts and maintenance. However, globalization means that some excellent manufacturers and suppliers may operate internationally, offering advanced technologies that may not be available locally.

Ultimately, selecting the right centerless tube grinding machine supplier involves careful consideration of these factors reputation, product range, technological advancements, and service support. By choosing a supplier wisely, manufacturers can invest in machines that will enhance their production capabilities, improve efficiency, and ultimately contribute to their bottom line.

In conclusion, the choice of a centerless tube grinding machine supplier can significantly affect manufacturing processes and product quality. As industries continue to evolve and competition intensifies, the importance of reliable suppliers will only grow. Therefore, manufacturers must conduct thorough research and assessments to ensure they select the best partner for their centerless grinding needs, paving the way for innovation and growth in their operations.