A revolution in the realm of machining is quietly reshaping industries by refining the tools and techniques employed in manufacturing processes. Among these groundbreaking advancements is the implementation of centerless grinding on surface grinders. Highly regarded for its precision and efficiency, this process has established its position as an essential component in modern manufacturing, supporting diverse sectors such as automotive, aerospace, and tool manufacturing.

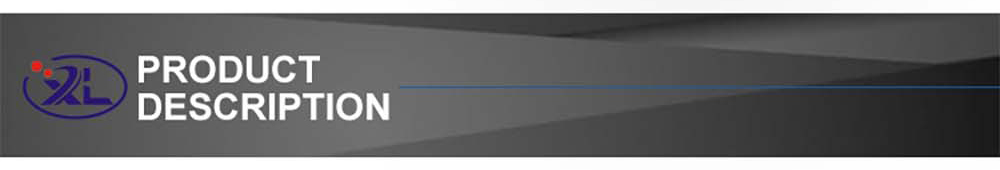

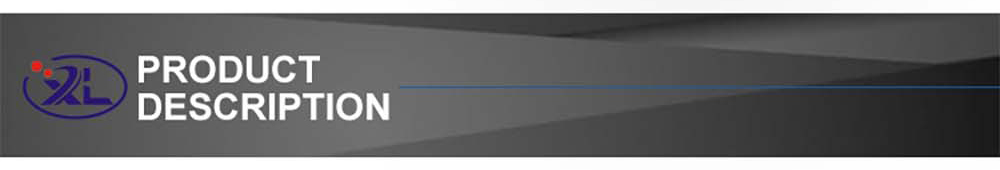

Centerless grinding, a process that removes material from a workpiece without the traditional requirements for centering or spindle support, offers notable advantages over conventional grinding techniques. It relies on the interplay between two rotary grinding wheels and support workpieces to maintain workpiece stability and achieve unparalleled precision.

One of the key benefits of centerless grinding in the use on surface grinders is operational efficiency. The lack of the traditional fixed center requirement leads to faster setup times and allows for smoother workflow processes. Manufacturers can achieve higher production volumes without sacrificing the quality of the finished product. This efficiency not only supports mass production but also reduces processing costs, providing a considerable return on investment which is particularly attractive to cost-sensitive industries.

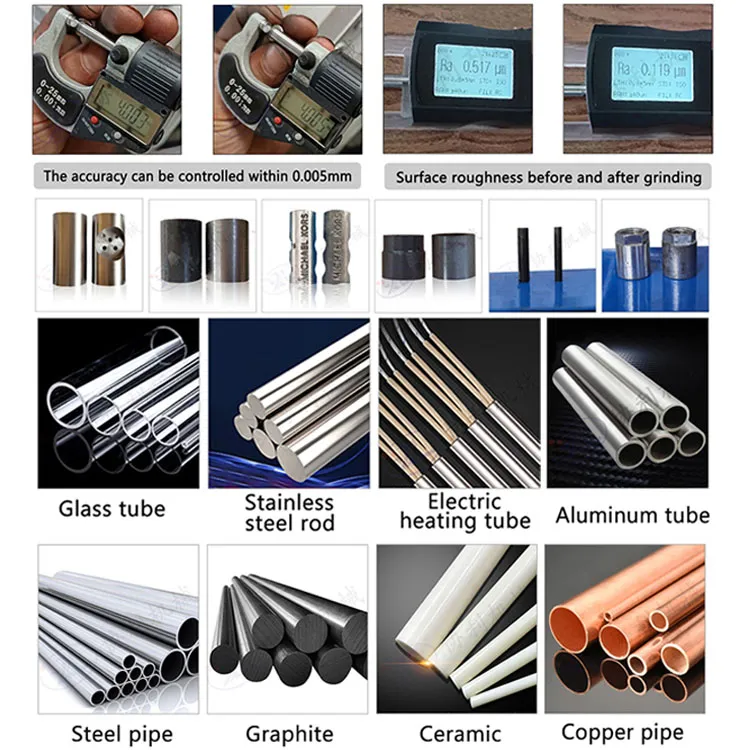

Precision is another hallmark of centerless grinding. By minimizing runout and achieving tighter tolerances, surface grinders equipped for centerless grinding produce superior surface finishes and dimensions that adhere to stringent industry standards. This level of precision makes the process ideal for manufacturing components that require flawless specifications, such as bearing rings, bushings, and engine parts.

From an expertise standpoint, centerless grinding on surface grinders demands a profound understanding of both equipment mechanics and material science. Operators must be skilled in adjustments relating to wheel alignment, pressure settings, and material feed rates. Compounded with the elasticity of the materials involved, these elements demand a high level of expertise to maximize the benefits of the process.

centerless grinding on surface grinder pricelist

The adoption of centerless grinding also signifies a commitment to innovation and sustainability, addressing the evolving needs of modern manufacturing. The process not only reduces material waste but also extends the lifespan of equipment by minimizing wear and tear. Proper training and technological updates further enhance the process’s sustainability, building a resilient manufacturing ecosystem.

Moreover, the credibility of centerless grinding is reinforced by its authoritative presence in landmark projects and its adoption by industry leaders. For example, aerospace companies trust centerless grinding for producing components that must withstand rigorous operational stress while complying with industry regulations. Such trust underscores the reliability of the process and its critical role in safeguarding operational integrity.

In the sphere of trustworthiness, centerless grinding processes have been extensively vetted for safety and compliance. Manufacturers prioritize systems that integrate necessary safety measures, including automated shut-off capabilities and monitoring systems to prevent mishaps. These protocols not only protect the equipment and workpieces but also ensure workforce safety, fostering a secure operational environment.

In conclusion, centerless grinding on surface grinders represents not only a transformative approach in material processing but also an emblem of innovation and technical prowess. As industries strive for superior quality and sustainability, this process encapsulates the ideals of modern machining. Through its implementation, manufacturers are equipped to meet the multifaceted demands of today's dynamic markets while ensuring optimal performance, competitive edge, and unwavering commitment to excellence.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.