Centerless grinding machines represent the pinnacle of precision in manufacturing processes. These machines, with their unique design and operational capabilities, cater to industries demanding high accuracy and fast production speeds. When selecting a centerless grinding machine manufacturer or supplier, several factors underscore the decision — from technical expertise to market reputation. Below, we delve into the intricacies of the industry, providing insights into why it’s crucial to partner with the right manufacturer.

Centerless grinding is a technique that allows for precision grinding of cylindrical parts without the need for centers to hold the workpiece. This method offers advantages in speed and finish, critical for applications in automotive, aerospace, and other high-tech industries. Unlike traditional grinding methods, centerless grinding offers consistent roundness, surface finish, and size accuracy, allowing for greater production efficiency.

Leading manufacturers of centerless grinding machines invest heavily in research and development to continually enhance machine performance. They understand the nuanced demands of the industries they serve and tailor their solutions to meet these specific requirements. Manufacturers with a proven track record in innovation often have developed proprietary technologies that significantly enhance machine performance. Whether it’s through improving the speed of the grinding process or enhancing the precision of each pass, these innovations set top manufacturers apart from their competitors.

An authoritative centerless grinding machine manufacturer typically provides comprehensive after-sales support. This includes training, maintenance, and the provision of spare parts. By offering training sessions and hands-on workshops, manufacturers ensure that the client’s workforce is adept at operating the machines efficiently, reducing downtimes and increasing productivity. An emphasis on maintenance and quick spare parts supply further underscores a manufacturer’s commitment to their clients’ success.

Insight into material compatibility is another area where reputable manufacturers differentiate themselves. Centerless grinding operations can involve materials ranging from hard metals to softer composites. Understanding how each material responds to different grinding techniques can significantly influence the choice of a machine. Experienced manufacturers consult closely with their clients to understand their specific material requirements, ensuring that the machine supplied is perfectly suited for the task.

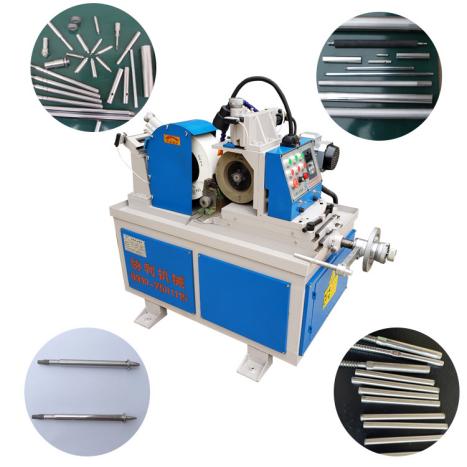

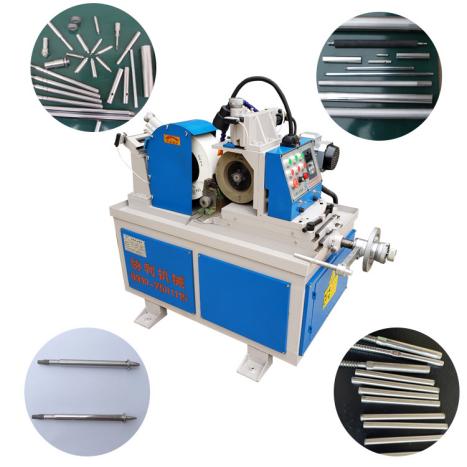

centerless grinding machine manufacturers supplier

Another critical factor is the manufacturer’s global reach and reliability. Operating within a global economy means that your manufacturing processes may demand support and solutions on an international scale. Many top manufacturers operate service centers around the globe, providing local support no matter where your operations are based. This globalization of services reiterates a supplier’s readiness to support international business growth.

Supply chain reliability also ties into environmental and regulatory considerations. Leading suppliers often integrate eco-friendly practices in machine operations, reducing the carbon footprint of your manufacturing processes. They maintain compliance with international standards and certifications, such as ISO and CE, ensuring that your company adheres to global safety and environmental regulations.

Trustworthiness in the selection of a manufacturer is further evidenced by industry testimonials and case studies. Real-world success stories from clients across different industries provide tangible proof of a manufacturer’s capability to deliver. Forums and online reviews can serve as valuable resources in assessing a manufacturer’s reputation. A strong portfolio of successful projects mirrors the company’s expertise and ability to meet the rigorous demands of high-precision industries.

In summary, the decision to select a centerless grinding machine manufacturer should rest on a foundation of meticulous research, expertise, and a proven record in both product innovation and customer support. The right partner will not only provide you with high-quality machines but also empower your operations through continuous support and improvements. By aligning with the right supplier, companies gain a critical edge in efficiency, product quality, and ultimately, competitiveness within their industries.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.