In the world of precision manufacturing, where accuracy and efficiency are paramount, the centerless grinder stands as a cornerstone in the realm of material fabrication. As industries relentlessly pursue advancements to maintain competitiveness, the spotlight turns to the profound impact of comprehensive centerless grinder training offered by leading manufacturers. This training is more than a mere instructional course; it is the gateway to mastering a machine that is integral to numerous industries such as automotive, aerospace, and medical device manufacturing.

To understand the significance of expert-driven centerless grinder training, one must first appreciate the intricate workings of the machine itself. Unlike traditional grinders,

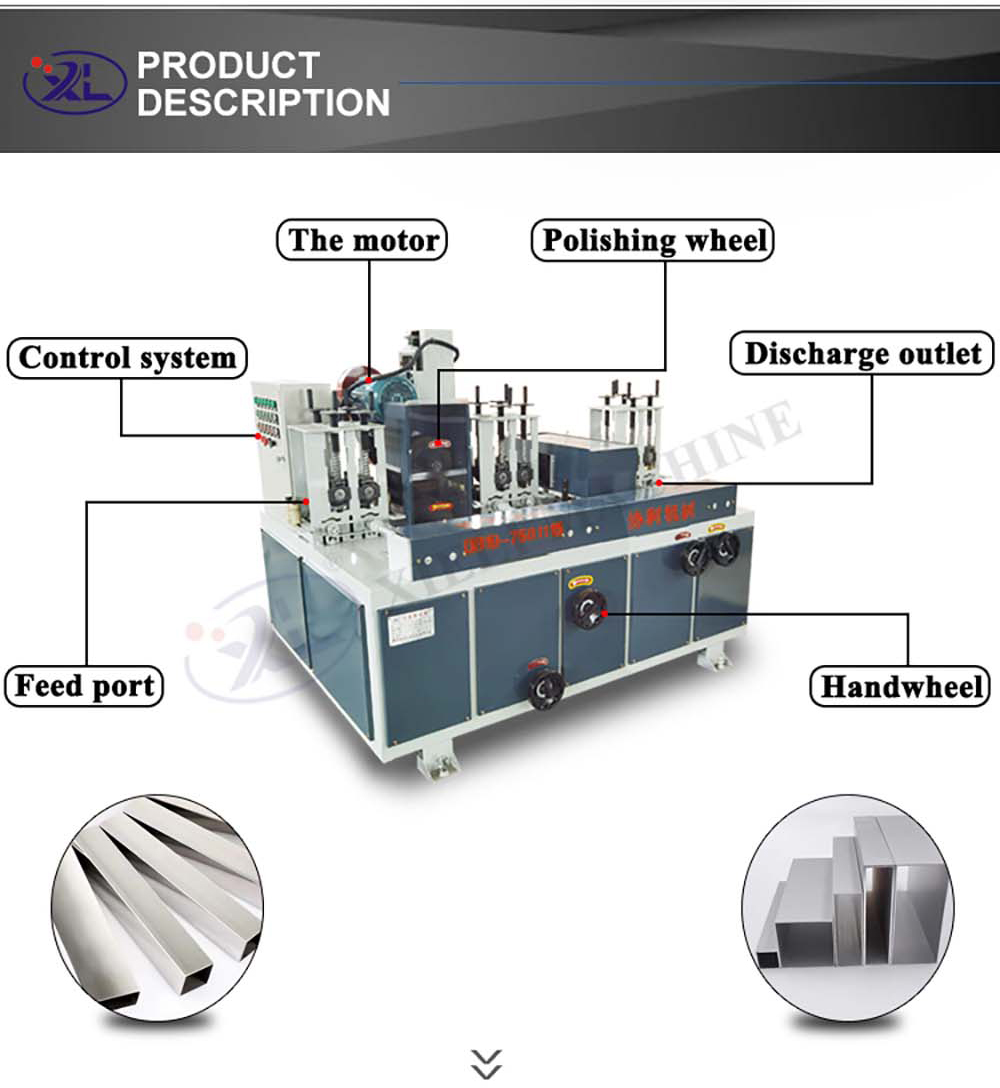

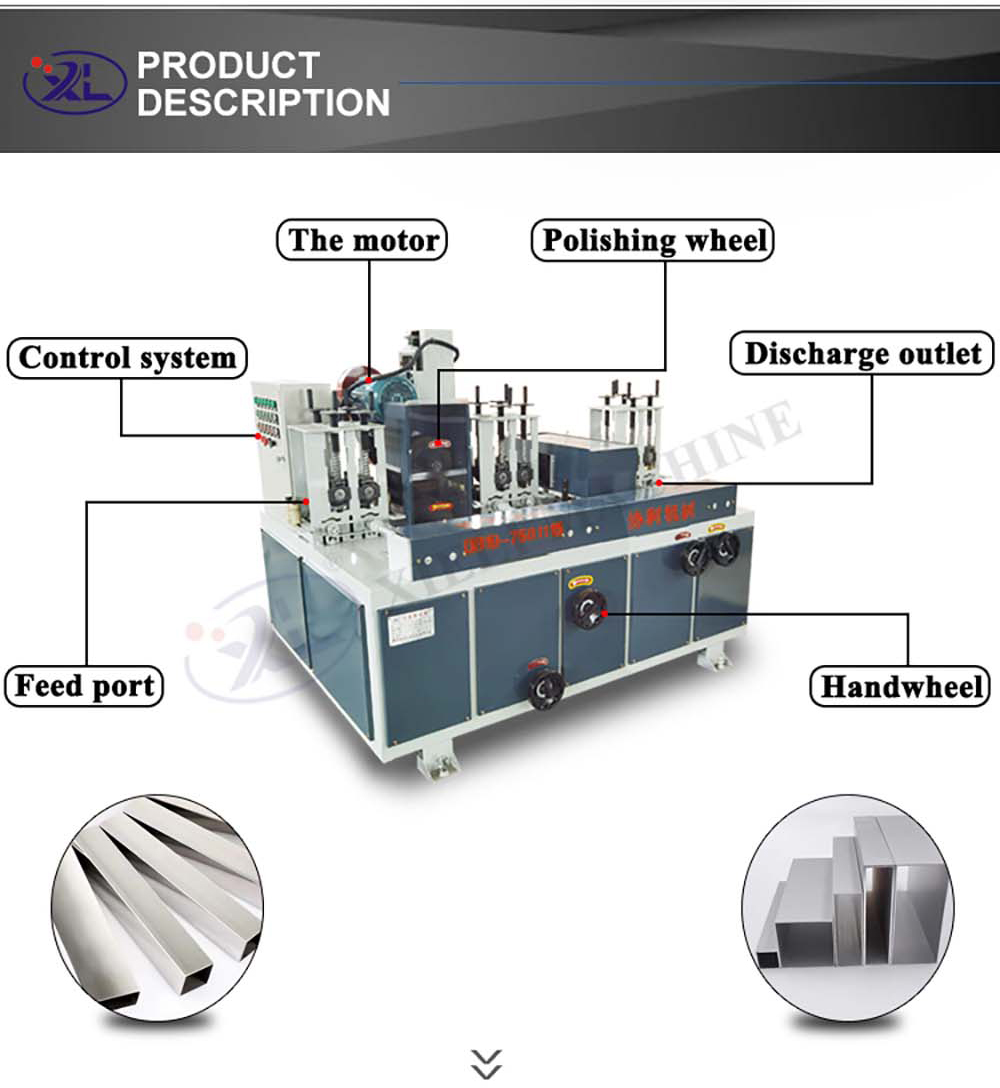

the centerless grinder does not rely on a spindle to secure parts. Instead, it utilizes dual wheels—a stationary one for grinding and a regulating wheel for maintaining rotational speed and part stability. The absence of a securing spindle enhances accuracy, but also introduces nuances requiring expert handling, underscoring the necessity of robust training programs.

Manufacturers of centerless grinders are uniquely positioned to offer unparalleled training programs. With their profound knowledge and insights into the intricate designs and functionalities of their machines, they ensure that operators are not merely performing tasks but mastering a craft. Training programs are meticulously designed to instill confidence and competence, reflecting the manufacturer's understanding that an expertly operated grinder results in optimal performance and prolonged machine life.

Expert training programs typically commence with foundational knowledge, delving into machine components, their purposes, and understanding the importance of precision settings. Trainees then engage with sophisticated modules covering the nuances of setup, maintenance processes, troubleshooting common issues, and adherence to safety protocols. This step-by-step approach empowers operators to handle the machine with expertise, maximizing productivity and minimizing downtime—a critical requirement in high-pressure manufacturing environments.

Moreover, manufacturers routinely update their training materials to incorporate the latest technological advancements and industry standards. This commitment ensures that clients receive not only an education in current best practices but also insights into emerging trends that could redefine their production processes. Through comprehensive updates, manufacturers affirm their authoritative stance, guiding industries through evolving landscapes.

centerless grinder training manufacturers

Trustworthiness forms the bedrock of these training sessions. Manufacturers offer credentials that serve as industry-recognized benchmarks for operational excellence. Certified operators are often seen as valuable assets within manufacturing teams due to their proven ability to maintain and optimize production lines effectively. This assurance of quality upholds the manufacturer’s reputation while instilling customer confidence.

A well-rounded understanding is not reserved solely for operators but extends to maintenance teams and managerial personnel. Manufacturers offer tailored courses depending on the role, equipping each attendee with focused, relevant knowledge that enhances organizational efficiency. A maintenance technician, for instance, gains insights into preventive care and diagnostics, significantly reducing unplanned outages and maintenance costs.

Lastly, the experiential aspect of training offered by manufacturers cannot be understated. Trainees benefit from engaging, hands-on practice, simulating real-world challenges and solutions. This immersion fosters a deeper understanding of the mechanics and encourages creative problem-solving while utilizing the latest in simulation technology and interactive modules. Thus, operators transition from learning theoretical concepts to implementing actionable, practical techniques in live settings.

In conclusion, centerless grinder training provided by manufacturers plays a crucial role in transforming operational efficiency and product accuracy. With roots firmly based in experience, expertise, authority, and trust, these training programs not only equip industry professionals with essential skills but also drive innovation and excellence across sectors. As industries continue to evolve, the steadfast commitment of manufacturers to impart in-depth, practical knowledge ensures that businesses remain at the forefront of manufacturing precision and reliability.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.