Centerless Grinder Machines for Sale An In-Depth Look

In the world of industrial manufacturing, precision and efficiency are paramount. This is where centerless grinder machines take center stage. Designed to grind cylindrical parts without the need for a machine spindle, centerless grinders have become a vital tool in many industries, from automotive to aerospace. The market for centerless grinder machines for sale has grown significantly, providing businesses with numerous options. This article will explore the advantages of using centerless grinders, their operating principles, key features to consider when purchasing, and the market trends driving their popularity.

The Advantages of Centerless Grinding

One of the main benefits of centerless grinding is its ability to handle high volume production with exceptional precision. Unlike traditional grinders, which require the part to be mounted on a spindle, centerless grinders use a simpler setup that allows multiple parts to be fed and processed more rapidly. This results in reduced cycle times and lower operational costs.

Another significant advantage is the ability to grind parts of various sizes and shapes. Centerless grinders can handle both small and large quantities of workpieces efficiently. The method also enables the grinding of long, slender parts like shafts and rods, which can be challenging to manage in conventional grinding setups.

Furthermore, the centerless grinding process typically leads to a superior finish on parts. The continuous contact between the workpiece and the grinding wheel helps achieve a smooth, consistent surface, which is essential for functionality and aesthetic quality.

How Centerless Grinders Operate

The operation of centerless grinders involves a few key components the grinding wheel, the regulating wheel, and the workpiece itself. The workpiece is positioned between the grinding wheel and the regulating wheel, and as the grinding wheel revolves, the workpiece is ground to the desired shape and size.

The regulating wheel plays a crucial role in controlling the speed and direction of the workpiece. It helps in guiding the part through the grinding process while ensuring accuracy. The unique design of centerless grinders allows for adjustments in the height and angle, enabling operators to fine-tune the grinding process according to the specific requirements of the parts being processed.

Key Features When Buying a Centerless Grinder

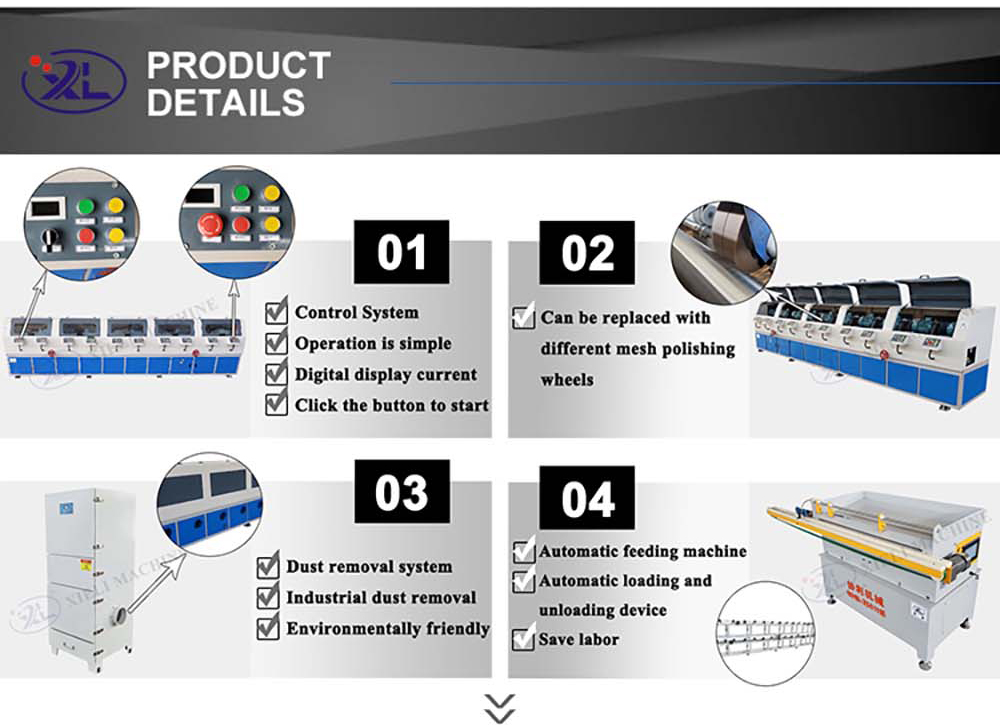

centerless grinder machine for sale product

When considering the purchase of a centerless grinder machine, several key features should be taken into account

1. Size and Capacity Evaluate the size of the machine and its capacity to handle the types of parts you need to grind. A larger grinder may handle bigger parts but require more space.

2. Precision and Tolerance Look for machines that offer high precision and can maintain tight tolerances, which are vital for many applications.

3. Type of Grinding Wheels Different grinding wheels can affect the finish and efficiency of the grinding process. Consider what types are compatible with the machine.

4. Ease of Use User-friendly controls and easy setup features can significantly reduce training time for operators and enhance productivity.

5. Service and Support Reliable after-sales service and availability of spare parts are crucial considerations to ensure minimal downtime in your operations.

Market Trends and Conclusion

The demand for centerless grinder machines is on the rise, driven by advancements in technology and increasing automation in manufacturing processes. The shift towards precision engineering and growing industries like electric vehicles and renewable energy is also fueling this market.

Investing in a centerless grinder machine can enhance productivity, reduce waste, and improve product quality. As businesses continue to seek innovative ways to remain competitive, the role of centerless grinders becomes increasingly vital. When exploring options for centerless grinder machines for sale, it is essential to consider the features and advantages that align best with your specific manufacturing needs and goals.