Crafting a premium product like the centerless grinder involves a comprehensive understanding of its intricate design, engineering, and practical applications. In machinist circles, few tools elicit the level of expertise and acclaim as the centerless grinder. Renowned for its efficiency and precision, this machine has revolutionized the way industries handle production challenges.

The concept of centerless grinding eliminates the need for the locating fixture or centers to hold the workpiece—a defining feature that underscores its uniqueness. Without the traditional limitations, machinists can achieve exceptional precision and a highly polished finish. This advantage is especially vital in manufacturing sectors where roundness and tolerance are crucial, such as aerospace, automotive, and tool manufacturing.

The effectiveness of the centerless grinder is anchored in its three-part system the grinding wheel, the regulating wheel, and the work blade. These components work harmoniously to ensure the workpiece is held stationary, while the abrasive and regulating wheels rotate. Such a setup provides superior consistency compared to traditional grinders.

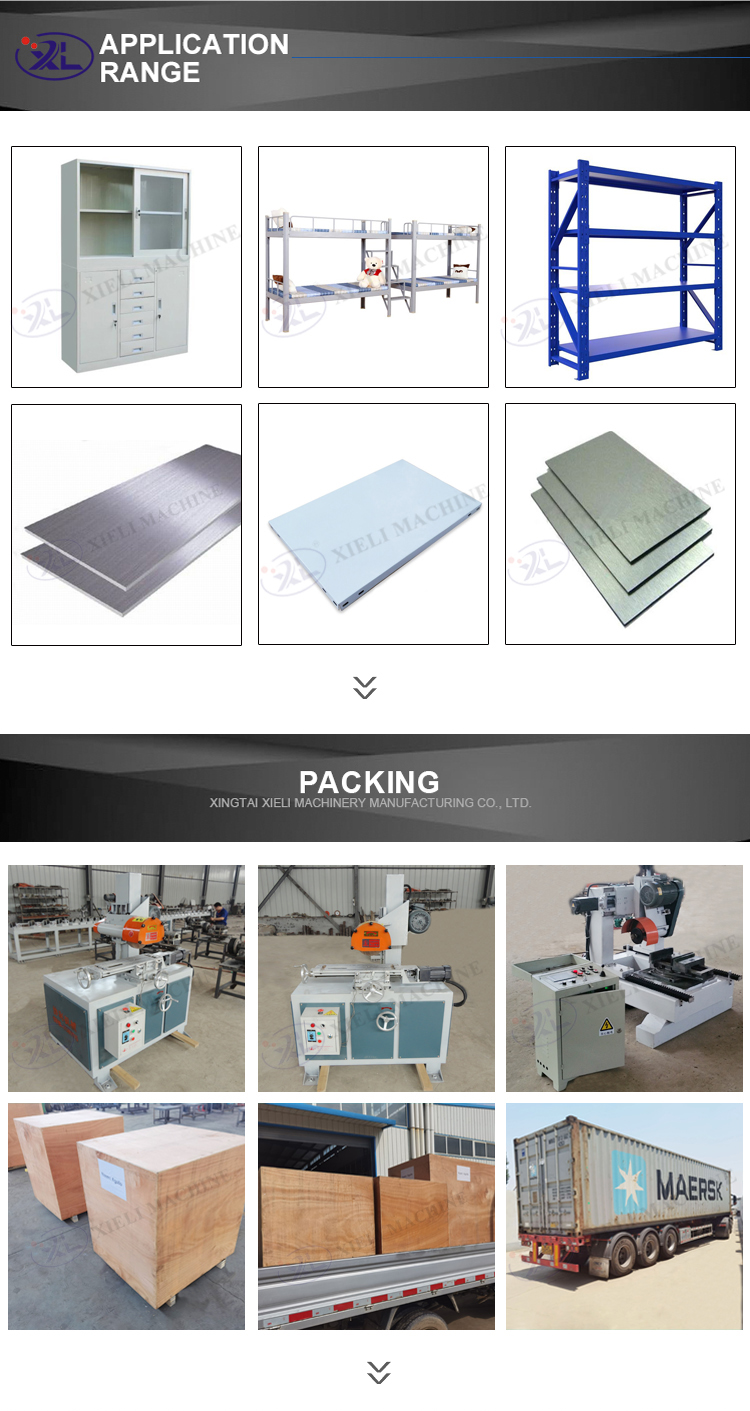

A significant advantage of centerless grinders is their ability to manage a wide range of workpiece sizes. The flexibility in handling various diameters without significant downtime in adjustments makes it a preferred choice for operations seeking efficiency and versatility. This adaptability is directly linked to its innovative design, making it an optimal solution for high-throughput environments.

From an engineering perspective, the centerless grinder brings forth an opportunity to explore advanced materials and coatings used in its construction. Modern versions deploy ceramics, carbides, and superabrasive materials for the wheels, enhancing the machine’s durability and cutting performance. This development aligns with the continuous pursuit of excellence in quality and lifespan.

centerless grinder

In terms of maintenance, centerless grinders demand a thorough understanding of their mechanical and operational intricacies. Regular preventive measures ensure longevity and sustained performance, positioning them as a reliable choice in high-stakes production lines. A well-maintained grinder not only performs optimally but also reduces the risk of downtime, safeguarding production schedules.

When operating a centerless grinder, expertise is paramount. Skilled operators who understand the nuances of the machine can maximize its capabilities, ensuring dimensional accuracy and surface finish that meet or exceed industry standards. Attention to factor adjustments like wheel speed, pressure, and alignment is crucial to mastering its use—a factor that underscores both the art and science of centerless grinding.

Centerless grinding also champions environmental stewardship. Due to reduced risk of material wastage and enhanced efficiency, this method aligns seamlessly with sustainable production practices. Maximizing materials and minimizing resource consumption are key benefits, positioning centerless grinding as a responsible choice for eco-conscious manufacturers.

For those seeking a competitive edge in the market, investing in a high-quality centerless grinder can place your production capabilities ahead of the rest. It allows for the seamless integration of cutting-edge technology with proven grinding principles, creating a synergy that caters to the demands of modern manufacturing disciplines.

In conclusion, the centerless grinder remains an indispensable asset in the machine tool arsenal, combining innovative design with practical applications. Its ability to adapt, perform, and deliver underpins its esteemed status across industries. Mastery in its operation not only requires technical proficiency but also a commitment to excellence—factors that lead to unparalleled operational success.