Understanding CE Certification and Parts of the Cinco 15 Centerless Grinder

The manufacturing landscape is continuously evolving, and with it comes the necessity for machines that not only deliver precision but also comply with international standards. One essential standard is the CE certification, which guarantees that products adhere to safety, health, and environmental protection standards for European markets. In this context, the Cinco 15 centerless grinder stands out as a versatile and reliable tool employed in various industrial applications.

What is a Centerless Grinder?

A centerless grinder is a type of machine tool that processes materials without the need for a fixed location or center. Unlike traditional grinding methods, where the workpiece is held between centers, centerless grinding uses two wheels the grinding wheel and the regulating wheel. This design allows for high-speed processing, ensuring optimal grinding of cylindrical parts, such as rods, tubes, and components of various shapes and sizes.

The Cinco 15 centerless grinder is notable for its efficiency and ability to deliver exceptional surface finish and dimensional accuracy. It is widely used in industries such as automotive, aerospace, and manufacturing, where precision and productivity are paramount.

Importance of CE Certification

CE certification is crucial for any equipment that targets the European market. It serves as a declaration by the manufacturer that the product meets all relevant EU directives and regulations. For manufacturers, achieving CE certification for the Cinco 15 centerless grinder means several things

1. Market Access CE marking is mandatory for many products sold in the European Economic Area (EEA). It facilitates trade by ensuring that products fulfill necessary safety requirements.

2. Consumer Confidence CE certification assures customers that the product complies with health, safety, and environmental standards. This can significantly enhance marketability and trust.

3. Legal Compliance The absence of CE certification can lead to penalties for non-compliance, including fines or even a ban on the sale of the product in Europe.

4. Quality Assurance Obtaining CE certification often requires rigorous testing and evaluation. This process helps manufacturers fine-tune their products and improve quality standards.

ce certification cinco 15 centerless grinder parts

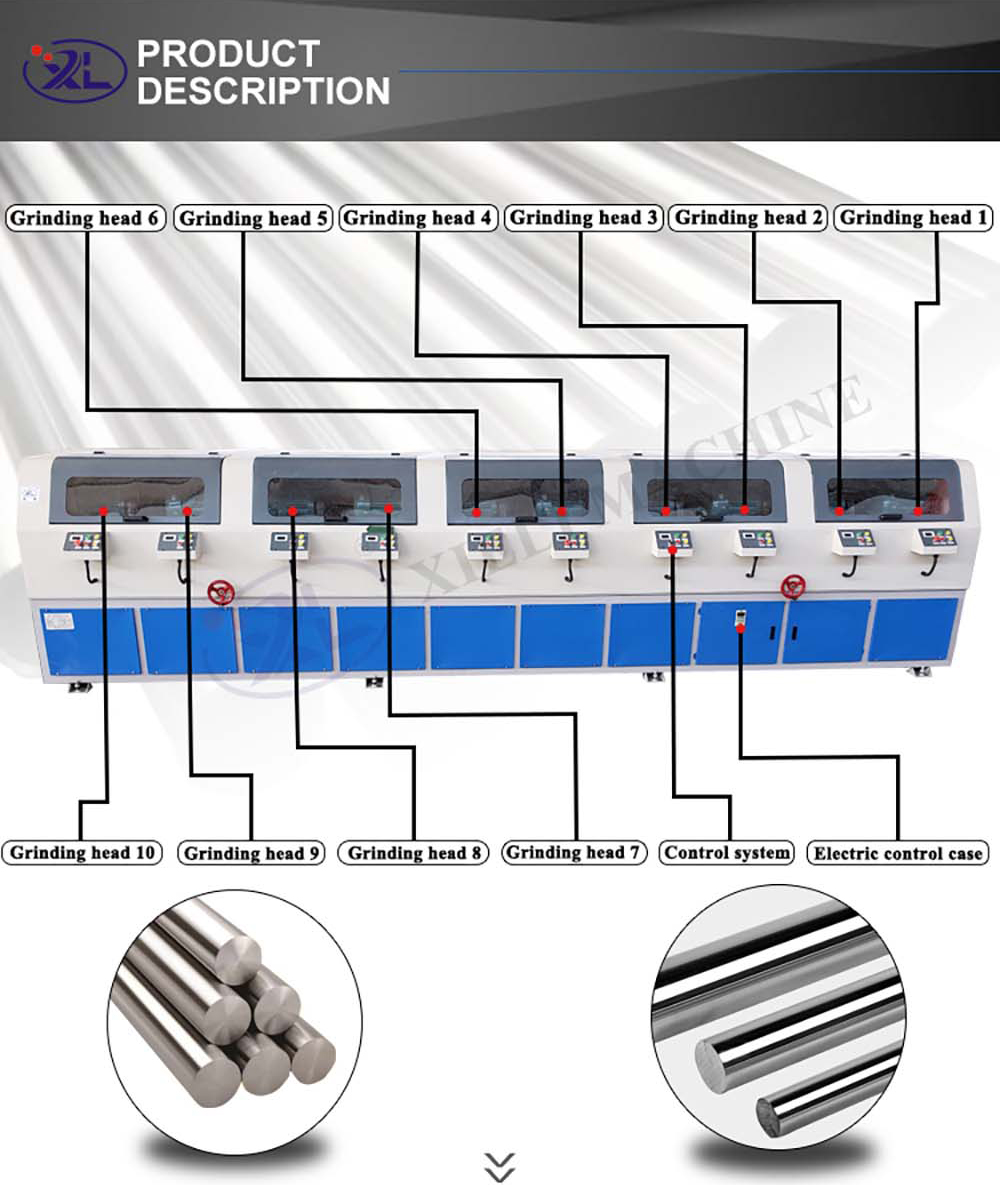

Key Parts of the Cinco 15 Centerless Grinder

Understanding the components of the Cinco 15 centerless grinder is essential for operators and maintenance personnel. Here are the main parts and their functions

1. Grinding Wheel The grinding wheel is the primary component responsible for removing material from the workpiece. It is made of abrasive particles that provide the necessary grinding action.

2. Regulating Wheel This wheel controls the speed of the workpiece as it passes through the grinder. By adjusting the regulating wheel's speed, operators can influence the surface finish and dimensional tolerances.

3. Work Rest Blade This component provides support for the workpiece during the grinding process. It is critical for ensuring that the workpiece remains stable and is ground evenly.

4. Adjustable Beds These are used to hold the grinding and regulating wheels in place. They can be adjusted to accommodate different workpiece sizes and ensure proper alignment and spacing.

5. Coolant System A coolant system is often integrated to flush away debris and cool the grinding process, which helps prevent overheating and extends the lifespan of the grinding wheels.

6. Control System Modern centerless grinders, including the Cinco 15, may come equipped with advanced control systems that can automate many aspects of the grinding process, enabling better precision and efficiency.

Conclusion

In an era where precision manufacturing is key to success, the Cinco 15 centerless grinder, with its CE certification, presents manufacturers with a reliable tool that meets stringent safety and performance standards. Understanding its components not only aids in operational efficiency but also emphasizes the importance of compliance with international norms. As industries continue to evolve, so too will the technology and standards that govern them, making CE certification an integral aspect of manufacturing excellence.