The Advantages of Investing in a Tube Buffing Machine

When it comes to finishing techniques in manufacturing, tube buffing machines have become essential tools for businesses that deal with metal, stainless steel, or aluminum tubing. These machines play a crucial role in enhancing the aesthetic appeal and functionality of tubular components. If you're considering purchasing a tube buffing machine, understanding its benefits is essential to maximizing your investment.

What is a Tube Buffing Machine?

A tube buffing machine is specifically designed to polish and buff tubes and pipes. These machines use abrasive wheels and polishing compounds to remove surface imperfections, resulting in a smooth and shiny finish. Whether you're in the automotive, aerospace, or any other industry utilizing tubular components, having a tube buffing machine can significantly enhance your end products.

Enhancing Product Aesthetics

One of the primary reasons businesses opt for a tube buffing machine is to improve the appearance of their products. A polished tube not only looks more appealing but also signifies quality and attention to detail. This polished finish is especially critical for products that are visible to consumers, such as furniture, automotive trims, and architectural elements. A good-looking product can dramatically influence customer perception and purchasing decisions, making a tube buffing machine a worthy investment for businesses seeking to improve their market competitiveness.

Increasing Durability and Lifespan

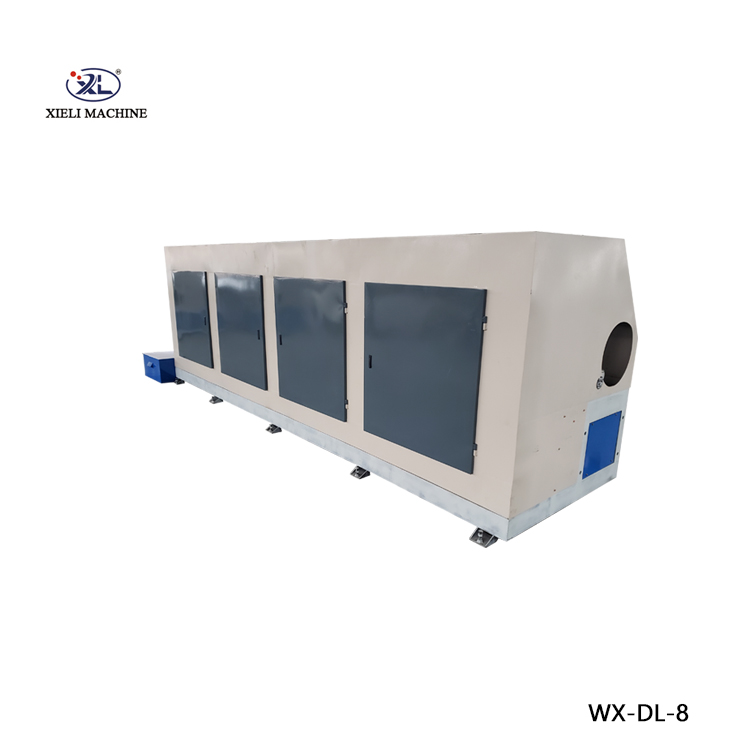

buy tube buffing machine

Beyond aesthetics, tube buffing machines play a pivotal role in enhancing the durability of tubular components. Polishing not only removes surface defects but also helps in the preparation of surfaces for plating, coating, or painting. A smooth surface reduces the risk of corrosion, particularly in metals that are prone to rusting. Furthermore, the absence of scratches and rough spots can prevent stress concentration, thereby increasing the lifespan of the products. Investing in a tube buffing machine ultimately means investing in the longevity of your products, which leads to reduced warranty claims and lower overall costs.

Efficiency and Productivity

Traditionally, tube polishing was a labor-intensive process, requiring skilled workers to manually buff surfaces. This not only consumed time but also carried a significant risk of human error, resulting in inconsistent finishes. Tube buffing machines, however, streamline this process by automating tasks and providing consistent, high-quality results. This efficiency translates into higher throughput, allowing manufacturers to meet increasing demands without compromising on quality. Moreover, the reduced need for manual labor can reallocate human resources to other critical areas, thus optimizing overall operational efficiency.

Versatility in Applications

Another significant advantage of tube buffing machines is their versatility. Many models are designed to accommodate various sizes and shapes of tubes and pipes, making them suitable for a wide range of applications. From small-diameter tubes used in intricate machinery to larger pipes in construction projects, you can find machines that fit your needs. This adaptability allows businesses to diversify their offerings and cater to different markets without the necessity of purchasing multiple specialized machines.

Conclusion

In conclusion, investing in a tube buffing machine can yield substantial benefits for manufacturers in various industries. Not only do these machines enhance the aesthetics and durability of tubular components, but they also improve efficiency and expand operational capabilities. By automating the polishing process, businesses can reduce labor costs, increase production rates, and ultimately provide superior products to their customers. If you’re looking to elevate your manufacturing process and ensure high-quality output, incorporating a tube buffing machine into your operations is a decision worth considering. With numerous options available in the market, you can choose a machine that best aligns with your business needs, ensuring a sound investment that pays off in the long run.