The Evolution and Significance of Automatic Centerless Grinding Machines in Manufacturing

In the world of manufacturing, precision and efficiency are paramount, especially in processes like grinding, which play a crucial role in producing high-quality components. One of the most significant advancements in this area is the development of automatic centerless grinding machines. These machines have revolutionized how manufacturers approach grinding tasks, enabling high-speed production of components while ensuring consistent quality.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding secures the workpiece between a grinding wheel and a regulating wheel. This setup allows for continuous production, making it suitable for batch processing of various materials, including metals, plastics, and ceramics.

Advantages of Automatic Centerless Grinding Machines

The introduction of automatic centerless grinding machines brings multiple advantages that enhance the manufacturing process

1. Precision and Consistency Automatic machines are designed to maintain tight tolerances and consistent quality over long production runs. By automating the grinding process, manufacturers can ensure uniformity in dimensions and surface finish, which is critical for components that require perfect fit and function.

2. Increased Productivity Automatic centerless grinding machines operate at high speeds, significantly reducing cycle times compared to manual grinding processes. This increase in productivity translates to lower operational costs and higher output rates, making it an attractive option for manufacturers trying to maintain competitiveness in a fast-paced market.

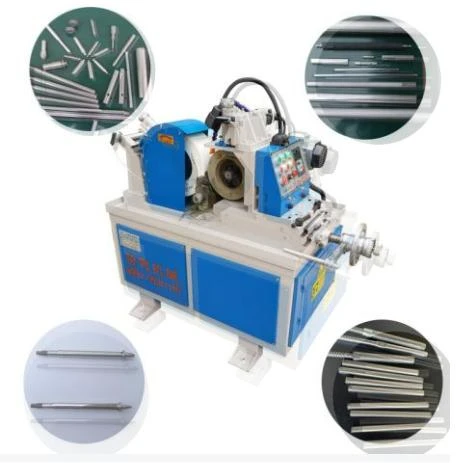

automatic centerless grinding machine factory

3. Reduced Labor Costs Automation minimizes the need for skilled labor to operate grinding machines. With fewer workers needed for setup and monitoring, manufacturers can reallocate their labor resources to other areas, enhancing overall operational efficiency.

4. Versatility Modern automatic centerless grinding machines are designed to accommodate a wide range of workpiece sizes and shapes. This flexibility allows manufacturers to easily switch between different products without the need for extensive reconfiguration, making it ideal for companies that deal with multiple product lines.

The Role of Technology in Advancements

The integration of advanced technologies such as CNC (Computer Numerical Control) and AI (Artificial Intelligence) has also played a pivotal role in enhancing the capabilities of automatic centerless grinding machines. CNC technology enables precise control over grinding parameters, ensuring optimal performance and consistency. Meanwhile, AI algorithms can monitor machine performance in real-time, proactively identifying potential issues before they lead to downtime or defects.

Industry Applications

Automatic centerless grinding machines find applications across various industries, including automotive, aerospace, medical devices, and consumer goods. For instance, in the automotive sector, these machines are used to grind components such as fuel injectors and shafts, ensuring they meet the stringent quality standards required for high-performance vehicles. In the medical field, precision ground components are crucial for surgical instruments and implants, where any deviation can impact patient safety.

Conclusion

As the demand for high-quality, precision-engineered components continues to rise, the role of automatic centerless grinding machines in manufacturing will only become more critical. Their ability to provide high-speed production, enhanced precision, and reduced labor costs make them indispensable tools in modern manufacturing processes. Investing in these advanced machines not only improves operational efficiency but also keeps businesses competitive in an ever-evolving marketplace. As technology continues to advance, it is fascinating to envision the future developments within this essential manufacturing function.