The Rise of Centerless Grinding A Closer Look at 340-20% Centerless Grinder Company

In the fast-paced world of manufacturing, precision and efficiency are paramount. One of the methods that has gained significant traction in this regard is centerless grinding. Companies around the globe are increasingly relying on centerless grinding technology, making sense of its robust benefits. Among these firms, the 340-20% Centerless Grinder Company has carved a niche for itself by delivering innovative solutions that meet the evolving needs of the machining industry.

Centerless grinding is a process that eliminates the need for setups that are typically required in traditional grinding methods. This technique allows the workpiece to be held between two wheels a grinding wheel and a regulating wheel. The grinding wheel performs the removal of material, while the regulating wheel controls the speed of the workpiece and its position during the grinding cycle. This unique setup enables fast, efficient, and cost-effective production, making it a preferred choice in various industries, including automotive, aerospace, and medical device manufacturing.

The Rise of Centerless Grinding A Closer Look at 340-20% Centerless Grinder Company

One of the key advantages of centerless grinding machines from the 340-20% Company is their adaptability. Whether handling small, intricate components or large, heavy workpieces, these machines can be tailored to suit diverse manufacturing needs. This flexibility allows manufacturers to produce a wide array of parts without lengthy downtimes for setup changes. In an industry where time equals money, the efficiency offered by centerless grinding is invaluable.

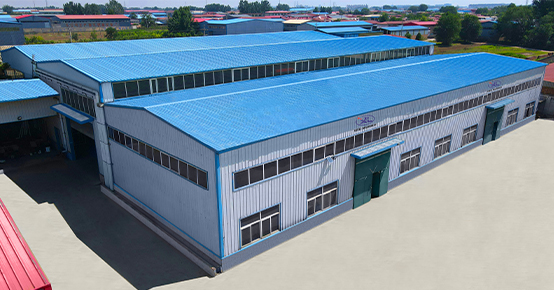

340-20 centerless grinder company

Moreover, the precision offered by the 340-20% grinders significantly reduces waste, which is another critical factor in modern manufacturing. With precise control over the grinding process, companies can minimize material loss while achieving tighter tolerances. This is particularly important for sectors where component accuracy is crucial, such as in the production of medical devices or aerospace components.

The customer service aspect of the 340-20% Centerless Grinder Company is equally impressive. The company places a strong emphasis on customer satisfaction, providing extensive support both pre- and post-purchase. Their team of experts is dedicated to assisting clients in selecting the right equipment for their specific applications and offering training to ensure optimal usage of the machines. Furthermore, the company provides comprehensive maintenance services, ensuring that the equipment operates at peak performance throughout its lifespan.

Sustainability is also becoming a focal point in manufacturing, and 340-20% is proactive in its approach to environmentally friendly practices. The centerless grinding systems are designed to maximize energy efficiency and to minimize waste—both in materials and in energy consumption. By integrating eco-friendly technologies, the company not only adheres to regulatory standards but also meets the growing demand from consumers and businesses alike for sustainable manufacturing practices.

In conclusion, the 340-20% Centerless Grinder Company stands out as a leader in the manufacturing sector, particularly in the realm of centerless grinding. Their dedication to quality, innovation, efficiency, and sustainability sets them apart in a fiercely competitive market. As industries continue to evolve, the role of centerless grinding will likely expand, and the 340-20% Company is well-positioned to meet these challenges head-on. With a focus on delivering exceptional machinery and customer service, they represent a reliable partner for anyone looking to enhance their manufacturing processes through advanced grinding technology.