The Importance of Polishing in Stainless Steel Tube Manufacturing

In the competitive landscape of modern manufacturing, the finishing processes play a critical role in determining the quality and performance of the final products. Among these processes, polishing is especially significant, particularly for stainless steel tubes, which find extensive use across various industries like automotive, aerospace, medical, and construction. Efficient and effective polishing not only enhances the aesthetic appeal of stainless steel tubes but also increases their durability and corrosion resistance. Thus, the emergence of specialized stainless steel tube polishing machine companies has marked a vital development in meeting these manufacturing demands.

What are Stainless Steel Tube Polishing Machines?

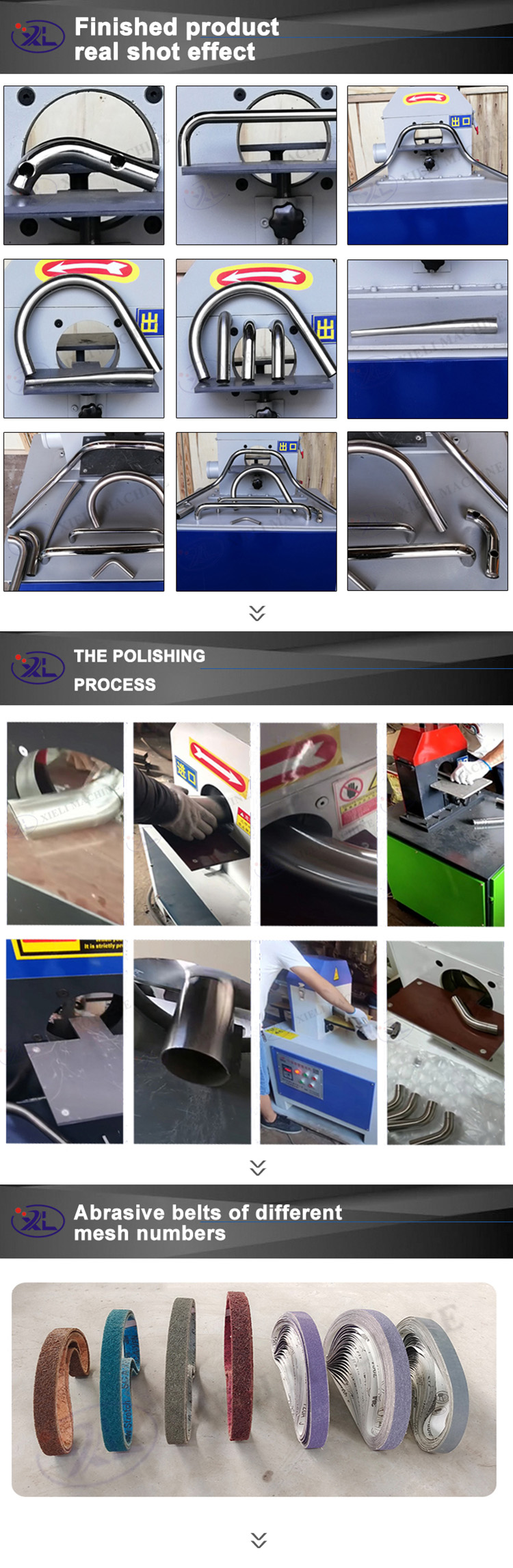

Stainless steel tube polishing machines are specialized equipment designed to perform the polishing process on stainless steel tubes. This process typically involves the removal of surface imperfections and oxidation from the tube's exterior, resulting in a smooth and shiny surface finish. The machines vary in complexity, ranging from manual units to fully automated systems, depending on the specific manufacturing needs and production volumes.

The polishing process itself involves several stages, including grinding, pre-polishing, and final polishing. Each step utilizes different types of abrasives and techniques to gradually achieve the desired finish. For instance, initial grinding might employ coarser abrasive materials to eliminate significant surface defects, while final polishing uses finer abrasives or buffing materials to create a mirror-like finish.

Why Choose a Professional Polishing Machine Company?

When manufacturing stainless steel tubes, the choice of a polishing machine company is crucial. Here are some key aspects that professional companies typically offer

1. Tailored Solutions Leading polishing machine manufacturers can provide customized solutions that cater to specific production requirements. Whether you need a machine designed for large-scale operations or for niche applications, a professional company can engineer a product that fits your needs.

2. Advanced Technology Reputable companies invest in the latest technologies and innovations in polishing machinery. This includes computer numerical control (CNC) systems that enhance precision, automation features that improve efficiency, and energy-efficient designs that reduce operational costs.

stainless steel tube polishing machine company

3. Quality Assurance A distinguished polishing machine company adheres to stringent quality control standards. This ensures that the machines perform consistently and reliably, reducing downtimes and enhancing overall productivity in the manufacturing process.

4. Support and Maintenance Beyond just selling machinery, reputable companies often offer ongoing support, maintenance services, and training for operators. This continuous support helps manufacturers maximize the lifespan and performance of their machines.

5. Research and Development Leading manufacturers commit to ongoing research and development to stay ahead in the industry. This commitment not only leads to innovative machinery designs but also ensures that companies are equipped to handle evolving market demands.

The Benefits of Polished Stainless Steel Tubes

Investing in high-quality polishing machines and processes offers numerous benefits for manufacturers of stainless steel tubes. Polished tubes have lower friction, which leads to more efficient fluid flow in applications like pipelines and heating systems. Additionally, the enhanced surface finish improves the tube's corrosion resistance, making polished stainless steel a preferred choice for environments that demand high standards of cleanliness and hygiene, such as the food and pharmaceutical industries.

Moreover, polished stainless steel tubes are more visually appealing, attracting customers and clients who prioritize aesthetics in product design. With industries increasingly focused on sustainability and durability, polished stainless steel is often seen as a long-lasting material, leading to increased customer satisfaction and loyalty.

Conclusion

The choice of an efficient stainless steel tube polishing machine company can significantly influence the quality and performance of finished products in many industries. As the demand for stainless steel tubes continues to grow, so does the importance of integrating advanced polishing technologies that enhance both functional performance and aesthetics. For manufacturers looking to thrive in today's competitive marketplace, investing in high-quality polishing equipment and partnering with leading machine manufacturers is not merely an option—it is a strategic necessity.