High-Quality Automatic Pipe Polishing Machines Revolutionizing Metal Finishing

In the realm of metal fabrication, quality and efficiency have always been paramount. One of the most critical operations in this sector is the polishing of metal pipes. With advancements in technology, high-quality automatic pipe polishing machines have emerged as vital tools, significantly enhancing productivity and finishing quality in manufacturing processes.

Automatic pipe polishing machines are designed to automate the tedious task of polishing, which traditionally required significant manual labor and time. These machines utilize a combination of innovative technologies and high-performance materials to achieve a superior finish on various types of pipes, including stainless steel, aluminum, and other metals.

Efficiency and Consistency

One of the primary advantages of using automatic pipe polishing machines is their ability to deliver consistent results. Unlike manual polishing, which can vary depending on the operator’s skill level and attention, automated systems are programmed to execute precise polishing parameters. This consistency is crucial for industries that require uniformity in product appearance and quality, such as aerospace, automotive, and medical device manufacturing.

Moreover, the efficiency of these machines cannot be overstated. With the capability to process multiple pipes simultaneously, automatic polishing machines significantly reduce the time required for metal finishing. This time-saving translates to increased throughput, allowing manufacturers to meet tight deadlines and enhance their overall production capacity.

Advanced Technology Integration

Modern automatic pipe polishing machines come equipped with advanced features that enhance their functionality. Many of these machines incorporate automated feeding systems, allowing for continuous operation without the need for constant monitoring. This feature not only improves productivity but also minimizes the likelihood of human error, further ensuring quality.

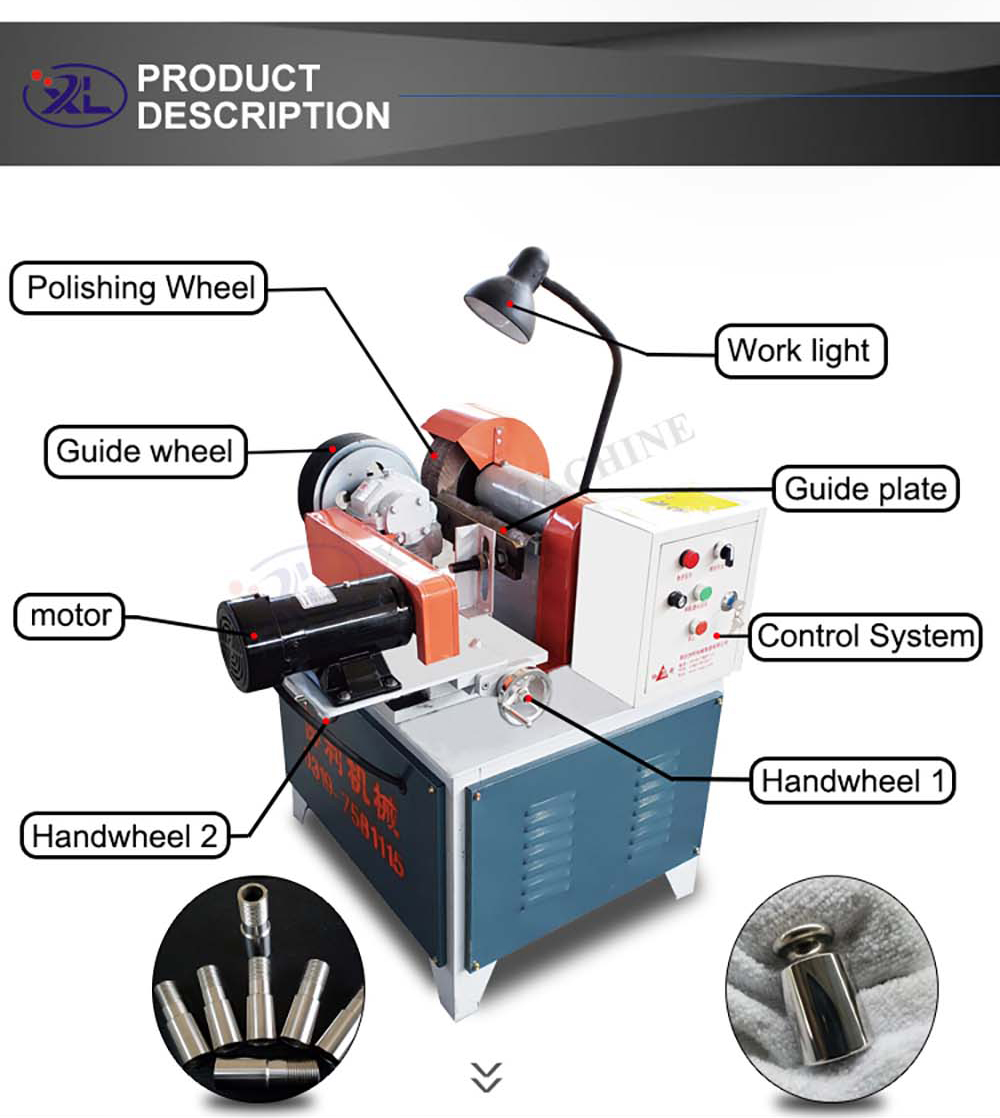

high quality automatic pipe polishing machine

Additionally, sophisticated control systems enable users to customize polishing processes according to the specific requirements of different projects. Operators can adjust parameters such as speed, pressure, and the type of polishing medium used, tailoring the process for optimal results on various materials and surface finishes.

Eco-Friendly Operations

As industries globally are leaning towards more sustainable practices, many manufacturers of automatic pipe polishing machines have embraced eco-friendly technologies. These machines often utilize water-based polishing compounds and energy-efficient motors, significantly reducing their environmental impact. By optimizing resource consumption, they not only contribute to sustainability but also help companies reduce operational costs.

Market Demand and Future Trends

The demand for high-quality automatic pipe polishing machines is on the rise. Industries are increasingly recognizing the value of investing in automated solutions for metal finishing due to the competitive advantages they offer. As manufacturing processes become more sophisticated, the need for machines that can deliver high-quality finishes quickly and efficiently is essential.

Looking ahead, the future of automatic pipe polishing machines seems promising. Ongoing advancements in artificial intelligence and machine learning can further enhance their capabilities. For instance, integrating smart technology could lead to predictive maintenance features that alert operators to potential issues before they disrupt production.

Conclusion

In conclusion, high-quality automatic pipe polishing machines play a crucial role in modern metal fabrication. Their ability to deliver consistent results, enhance efficiency, and incorporate advanced technology makes them invaluable assets for manufacturers seeking to improve their operations. As industries continue to evolve, these machines will undoubtedly remain at the forefront of metal finishing innovation, driving higher standards of quality and productivity in the manufacturing sector. Investing in such technology not only represents a commitment to excellence but also paves the way for a more efficient and sustainable future in metalworking.