Exploring the Benefits of ODM Automatic Centerless Grinding Machines

In the realm of precision machining, the demand for efficiency and accuracy is paramount. One of the groundbreaking advancements that have significantly enhanced manufacturing processes is the ODM Automatic Centerless Grinding Machine. This innovative equipment offers a myriad of benefits that can streamline operations and improve product quality in various industries.

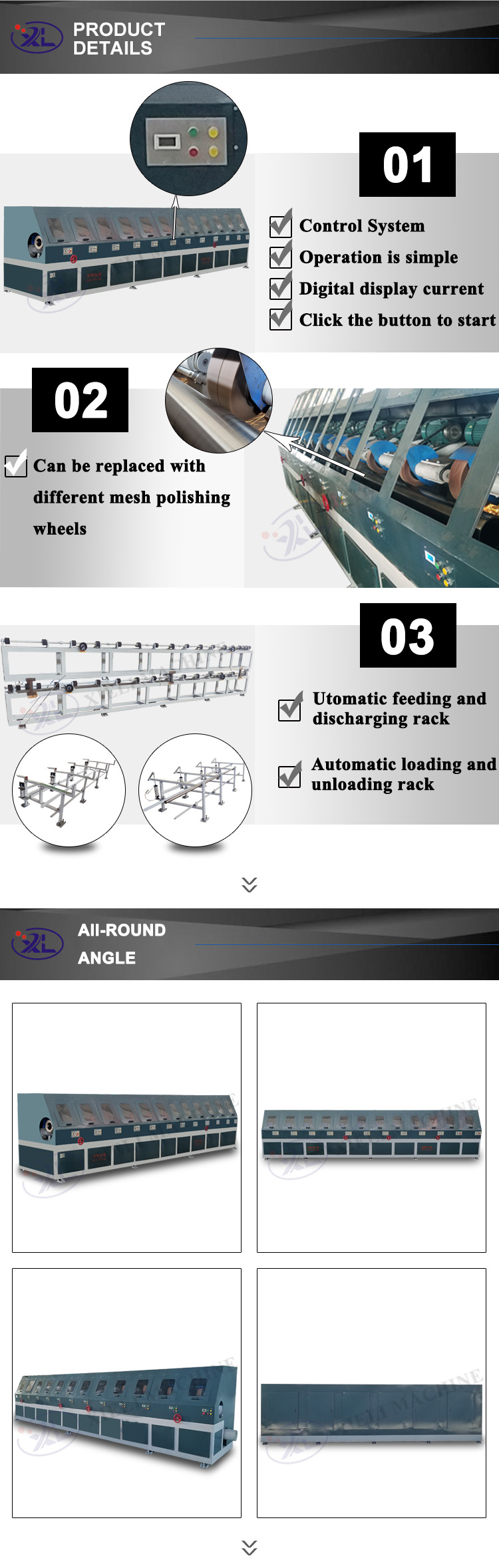

Centerless grinding is a manufacturing process that involves grinding the outer diameter of a workpiece without the use of a spindle. This technique is particularly advantageous for producing cylindrical parts with high precision and minimal tolerance. The ODM Automatic Centerless Grinding Machine takes this concept to the next level by incorporating automation features that minimize human intervention and maximize output.

One of the most significant advantages of ODM machines is their enhanced productivity. With automated feeding systems and advanced software controls, these machines can operate continuously, significantly reducing manufacturer downtime. The ability to handle multiple workpieces simultaneously allows for higher throughput, making them ideal for high-volume production environments. This increase in efficiency translates into reduced manufacturing costs and enables companies to meet tight delivery schedules while maintaining quality standards.

odm automatic centerless grinding machine

Moreover, the ODM Automatic Centerless Grinding Machine excels in achieving consistent results. The advanced technology utilized in these machines ensures that each part is ground uniformly, minimizing variations and defects. This consistency is crucial in industries such as automotive, aerospace, and medical devices, where even minor inconsistencies can lead to catastrophic failures or rejections. By maintaining tight tolerances, manufacturers can enhance product reliability and customer satisfaction.

Another notable feature of the ODM Automatic Centerless Grinding Machine is its flexibility. These machines can be configured to handle a variety of materials, including metals, plastics, and composites, making them versatile tools suitable for different applications. Operators can also easily adjust parameters such as grinding speed, wheel pressure, and feed rates to accommodate different workpiece specifications. This adaptability not only broadens the scope of production but also allows manufacturers to respond swiftly to changing market demands.

Furthermore, the safety and ergonomic design of ODM Automatic Centerless Grinding Machines cannot be overlooked. By automating the grinding process, these machines reduce the risk of operator injuries related to manual handling and excessive exposure to hazardous conditions. Additionally, the user-friendly interfaces and monitoring systems make it easier for operators to oversee the grinding process, ensuring a safer working environment.

In conclusion, the ODM Automatic Centerless Grinding Machine represents a significant advancement in the manufacturing sector. Its ability to improve productivity, maintain consistent quality, offer flexibility, and enhance safety makes it an invaluable asset for businesses aiming to stay competitive in today’s fast-paced market. As technology continues to evolve, it is evident that such innovations will play a crucial role in shaping the future of manufacturing, driving efficiency, and fostering growth across various industries. Investing in these machines is not merely a choice but a strategic decision that can lead to long-term success.