Unlock unparalleled surface finishes for metal tubes and pipes. This comprehensive guide explores the technology behind the modern pipe polishing machine, from industry trends and technical specifications to real-world applications and choosing the right manufacturing partner.

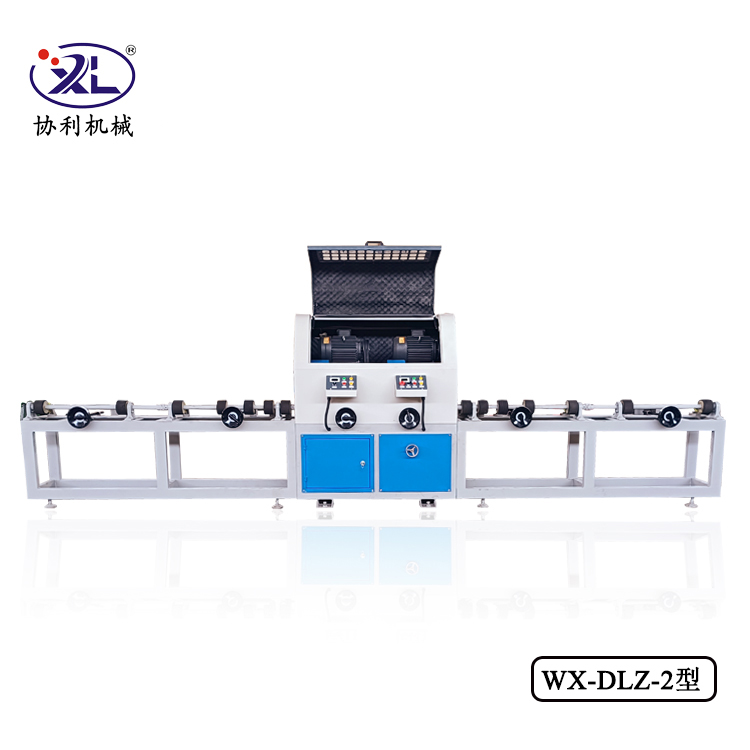

Introducing the Xielizz Round Pipe Metal Polishing Machine for Steel Tube

At the forefront of surface finishing technology is our flagship model, the Round Pipe Metal Polishing Machine. Engineered for precision, efficiency, and durability, this machine is the definitive solution for achieving mirror-like or satin finishes on a variety of round metal tubes.

Engineered for Peak Performance

The Xielizz tube polisher is not just a piece of equipment; it's a comprehensive finishing system. Designed to meet stringent industry standards like ISO 9001 and CE certified, it provides a consistent, high-quality finish, reducing manual labor costs and increasing production throughput. Its robust construction ensures long operational life, even in the most demanding industrial environments.

Key features include a multi-station polishing head configuration, variable speed control for both polishing wheels and the workpiece conveyor, and an integrated dust collection system for a safer, cleaner workspace. Whether you're in the automotive, construction, or furniture industry, this machine delivers exceptional results on materials like stainless steel, aluminum, copper, and carbon steel.

View Product Details & Inquire

Industry Trends & Market Outlook

The global demand for high-quality finished metal products is on the rise. Industries from architectural design to medical devices require components with precise surface characteristics for both aesthetic appeal and functional performance (e.g., corrosion resistance, hygiene). A professional pipe polishing machine is central to meeting this demand.

Fig. 1: Projected Growth of the Metal Finishing Equipment Market (Source: Industry Analysis Reports, 2023)

Market data indicates a compound annual growth rate (CAGR) of approximately 4.5% for the metal finishing equipment market. This growth is driven by:

- Stricter Quality Standards: Regulations in industries like food processing (FDA standards) and aerospace demand smoother, non-porous surfaces to prevent bacterial growth and ensure structural integrity.

- Automation in Manufacturing: Businesses are increasingly adopting automated solutions like a multi-station pipe polisher to enhance productivity, ensure consistency, and reduce reliance on manual polishing, which can be inconsistent and labor-intensive.

- Aesthetic Demands: In consumer-facing industries like high-end furniture, automotive trim, and architectural fixtures, a flawless polished finish is a key differentiator and a mark of quality.

Core Technical Specifications: A Deep Dive into the Round Pipe Metal Polishing Machine

Understanding the technical parameters of a pipe polishing machine is crucial for evaluating its suitability for your specific needs. The Xielizz model is designed with versatility and power in mind. Below is a detailed breakdown of its key specifications.

| Parameter | Specification | Description & Industry Significance |

|---|---|---|

| Product Name | Round Pipe Metal Polishing Machine For Steel Tube | Specifically designed for cylindrical workpieces, ensuring optimal contact and uniform finish. |

| Applicable Pipe Diameter | Ø10mm - Ø150mm (Customizable) | Covers a wide range of common pipe sizes in industries like plumbing, furniture, and handrails. Customization allows for larger or smaller diameters. |

| Applicable Pipe Length | ≥ 500mm | The conveyor system is optimized for standard industrial pipe lengths. |

| Number of Polishing Heads | 2 to 12 stations (Model Dependent) | Multi-station design allows for a progressive polishing process, from coarse grinding to fine mirror polishing in a single pass, drastically increasing efficiency. |

| Polishing Wheel Speed (RPM) | 1800 - 2800 RPM (Variable) | Variable speed control is critical. Higher RPMs are used for aggressive material removal, while lower speeds are for fine finishing, preventing heat damage. |

| Workpiece Feeding Speed | 1 - 8 m/min (Variable) | Adjustable feeding speed allows the operator to control the finish quality. Slower speeds result in a finer, more consistent polish. |

| Achievable Surface Roughness (Ra) | Down to Ra ≤ 0.1 μm | Achieves a mirror finish, meeting stringent requirements for sanitary, decorative, and high-performance applications. Ra is a measure of surface texture. |

| Total Power | 15 kW - 45 kW (Model Dependent) | Indicates the machine's processing power. Higher power allows for polishing larger diameters and harder materials more effectively. |

| Control System | PLC with Touch Screen HMI | Provides user-friendly operation, precise control over all parameters, and the ability to save polishing "recipes" for different jobs. |

| Certification | CE, ISO 9001 | Compliance with international standards for safety (CE) and quality management (ISO 9001), ensuring reliability and operational safety. |

From Raw Material to Flawless Finish: Our Manufacturing Excellence

A superior pipe polisher is born from a meticulous manufacturing process. We adhere to the highest standards, combining robust materials with precision engineering to guarantee performance and longevity.

1. Design & Engineering

CAD/CAE modeling for structural integrity and performance simulation. All designs comply with ANSI/ASME safety standards.

2. Frame Casting

Machine base made from high-tensile HT250 cast iron for maximum vibration damping and stability during operation.

3. CNC Machining

Key components like spindles and guide rollers are precision-machined by 5-axis CNC centers to ensure tolerances within 0.01mm.

4. Assembly & Wiring

Assembled by certified technicians. Electrical systems use Schneider/Siemens components and conform to CE safety directives.

5. ISO 9001 Testing

Each machine undergoes a 72-hour continuous operation test. Surface finish (Ra) is measured, and all functions are verified.

Unlocking Superior Performance: Key Technical Advantages

Choosing the Xielizz tube polisher provides a competitive edge through superior engineering and thoughtful design. Our machine isn't just about polishing; it's about optimizing your entire finishing workflow.

✔ High-Efficiency Multi-Station Design

Our progressive polishing system allows for multiple grit stages in one pass. This reduces handling time and can increase throughput by up to 300% compared to single-head machines or manual polishing.

✔ Unmatched Finish Consistency

The automated conveyor and pressure-controlled polishing heads eliminate human error, ensuring every inch of the pipe receives a uniform finish, from start to finish, batch to batch.

✔ Robust and Durable Construction

With a heavy-duty cast iron base and components made from hardened steel (HRC 55-60), our machine is built for 24/7 operation with an expected service life exceeding 15 years with proper maintenance.

✔ Operator Safety and Ergonomics

Fully enclosed polishing stations, emergency stop systems, and an efficient dust extraction port (connects to standard collectors) create a safer work environment compliant with OSHA guidelines.

✔ Energy-Efficient Motors

We utilize IE3 premium efficiency motors, which can reduce energy consumption by 5-8% compared to standard motors, lowering your operational costs over the machine's lifetime.

✔ Versatility and Adaptability

Quick-change mechanisms for polishing wheels and guide rollers allow for rapid setup for different pipe diameters and finish requirements, minimizing downtime between jobs.

Choosing the Right Partner: Xielizz vs. Generic Alternatives

The market offers various options for a pipe polishing machine. However, not all are created equal. The initial purchase price is only one part of the equation; total cost of ownership (TCO) and return on investment (ROI) are what truly matter. Here’s a comparison that highlights the Xielizz difference.

| Feature / Aspect | Xielizz Round Pipe Polishing Machine | Generic/Low-Cost Competitor |

|---|---|---|

| Construction & Stability | Heavy-duty cast iron frame (HT250), excellent vibration damping. Superior stability. | Welded steel plate frame, prone to vibration, affecting finish quality. |

| Precision & Control | PLC control with variable speed for wheels and feed. High precision. | Basic on/off controls, fixed speeds. Limited process control. |

| Service Life & Reliability | 15+ year design life, premium bearings (SKF/NSK), Schneider/Siemens electronics. | 5-7 year typical lifespan, lower-grade components, frequent breakdowns. |

| Finish Quality (Achievable Ra) | Mirror finish capable (Ra ≤ 0.1 μm). Exceptional consistency. | Typically limited to satin/brush finish (Ra > 0.4 μm). Inconsistent results. |

| Customization | ✔ Full customization for diameter, length, and special fixtures. | ✖ Limited or no customization available. |

| After-Sales Support | 2-year warranty, 24/7 technical support, on-site installation & training. | Limited warranty (6-12 months), difficult to reach support. |

| Safety Compliance | ✔ CE Certified, full safety guarding. | Often lacks proper guarding and international safety certification. |

Versatile Applications Across Diverse Industries

The true value of a high-quality pipe polisher is its ability to serve a wide array of applications. Our machine is a critical asset in any industry that relies on perfectly finished tubes and pipes.

Fig. 2: Typical Application Distribution of our Pipe Polishing Machines

- Petrochemical & Energy: Polishing pipes for pipelines and heat exchangers improves fluid dynamics and enhances corrosion resistance, extending component life in harsh environments.

- Food & Beverage / Pharmaceutical: Achieving a sanitary, mirror-like finish (low Ra value) on stainless steel tubing is critical to prevent bacterial contamination and comply with FDA and 3-A Sanitary Standards.

- Architectural & Construction: Creating flawless satin or mirror finishes on handrails, balustrades, and decorative columns for commercial and residential buildings.

- Automotive: Polishing exhaust systems, roll bars, and other tubular components for both aesthetic appeal and performance.

- Furniture Manufacturing: Providing a high-end, durable finish for metal components in modern chairs, tables, and lighting fixtures.

- Marine Applications: Polishing stainless steel railings and fittings to withstand saltwater corrosion and maintain a pristine appearance.

Tailored to Your Needs: Custom Pipe Polisher Solutions

We understand that standard solutions don't fit every production need. Our engineering team has over 15 years of experience in creating bespoke machine configurations. We demonstrate our authority and experience by offering tailored solutions that generic suppliers cannot match.

Non-Standard Diameters

We can engineer a pipe polishing machine to handle micro-tubes (e.g., 200mm for infrastructure).

Integrated Automation

Our solutions can include automatic loading/unloading systems, robotic integration, and in-line quality inspection systems for fully autonomous operation.

Specialty Materials

We can configure machines with specific polishing media, speeds, and pressures for challenging materials like titanium, Inconel, or exotic alloys.

Complex Shapes

While this model is for round pipes, we also offer solutions for square, rectangular, and even oval tubes. Contact us with your specific requirements for a custom quote.

Real-World Success: Application Case Studies (Experience)

Our claims are backed by the success of our clients. Here are some examples of how the Xielizz pipe polishing machine has transformed production floors.

Case Study 1: Automotive Exhaust Manufacturer

"We replaced our manual polishing line with a 6-station Xielizz machine. The results were immediate. Our throughput for stainless steel exhaust tips increased by 250%, and the finish consistency is perfect every time. We passed a major OEM quality audit with flying colors thanks to the measurable Ra values we can now achieve. The ROI was less than 12 months."

Case Study 2: Architectural Metal Fabricator

"For our high-end projects, the finish is everything. The Xielizz tube polisher allows us to offer our clients a true #8 mirror finish on stainless steel handrails, which was previously very time-consuming and expensive to outsource. Bringing this capability in-house has improved our profit margins and shortened project lead times. The machine paid for itself on two large hotel projects alone."

Our Commitment to You: Trust and Reliability (Trustworthiness)

Comprehensive Warranty

We stand by our quality with an industry-leading 24-month warranty on all major components. This demonstrates our confidence in the machine's durability and reliability.

Global Customer Support

Our team of expert engineers is available 24/7 via email, phone, or video call to assist with troubleshooting, maintenance, and operational questions. We provide support for the entire lifecycle of the machine.

Guaranteed Delivery & Installation

We offer transparent delivery timelines (typically 30-45 days for standard models) and provide optional on-site installation and operator training services worldwide to ensure you get up and running smoothly.

Frequently Asked Questions (FAQ)

Our pipe polishing machine is highly versatile and can effectively polish a wide range of metals. The most common are Stainless Steel (304, 316, etc.), Carbon Steel, Aluminum, Copper, and Brass. With the correct selection of polishing wheels (e.g., sisal, cloth, or nylon) and polishing compounds, it can also be adapted for harder alloys like Titanium and Inconel. The key is to match the abrasive material and machine parameters to the specific metal's properties.

The machine can achieve a mirror finish with a surface roughness (Ra) value as low as 0.1 micrometers (μm). Surface roughness is an industry-standard measurement (defined by ISO 4287) of the fine-scale variations on a surface. A lower Ra value indicates a smoother, more reflective surface. Achieving Ra ≤ 0.1 μm typically requires a multi-station process, starting with a coarse abrasive belt (e.g., 80 grit) and progressing through finer grits to a final buffing stage with a soft cloth wheel and polishing compound.

A multi-station design allows for a "single-pass" finishing process. Each station is fitted with a progressively finer abrasive or polishing wheel. A raw pipe enters at the first station for coarse grinding to remove scale and imperfections. It then automatically moves to the second station for intermediate polishing, the third for fine polishing, and so on, until it exits the final station with the desired finish. This eliminates the need to stop production to change wheels on a single-head machine, dramatically increasing throughput and reducing labor.

Installation requires a solid, level concrete floor to ensure stability. Power requirements depend on the model (number of heads), typically ranging from a 3-phase, 380V/50Hz to 480V/60Hz supply. We provide a detailed pre-installation guide and can configure the machine for your region's specific electrical standards. A connection point for a dust collection system (typically a 150-200mm duct) is also required to maintain a safe and clean working environment.

The machine frame and core components are designed for a service life of over 15 years. The main consumable parts are the polishing wheels/belts and polishing compounds, which wear down with use. Their lifespan depends on the material being polished, the pressure applied, and the desired finish. Other wear parts, such as conveyor belts and guide rollers, are designed for easy replacement and are readily available from our spare parts department.

This specific model, the Round Pipe Metal Polishing Machine, is optimized for straight, cylindrical pipes. Polishing bent pipes or complex shapes like T-fittings requires a different type of machine, such as a robotic polishing cell or a manual machine with specialized fixtures. However, we have extensive experience in providing custom solutions. Please contact our engineering team with your drawings and requirements, and we can recommend or design the appropriate equipment for your unique application.

Safety is a paramount design consideration. All our machines are CE certified and include:

- Full Enclosures: The polishing heads are fully guarded to prevent contact with moving parts and contain sparks and debris.

- Emergency Stop Buttons: Multiple E-stops are located at strategic points for immediate shutdown.

- Overload Protection: All motors are equipped with thermal overload relays to prevent damage.

- Dust Collection Ports: An integrated dust hood at each station allows for efficient connection to an external dust collector, minimizing airborne particles.

Advancing Your Production with a Premier Tube Polisher

Investing in an advanced pipe polishing machine like the Xielizz model is a strategic decision that impacts quality, efficiency, and profitability. By leveraging superior technology, robust construction, and dedicated support, you can meet the increasing demands of the modern market and position your business as a leader in quality. We invite you to contact us to discuss your specific finishing challenges and discover how we can engineer the perfect solution for you.

References and Further Reading:

- Bhushan, B. (2013). Introduction to Tribology (2nd ed.). John Wiley & Sons. - Provides in-depth scientific principles behind friction, wear, and lubrication relevant to polishing processes. Referenced at: Wiley Online Library

- Hocheng, H., & Chen, Y. (2014). A review of the polishing of metals. International Journal of Machine Tools and Manufacture, 81, 1-18. - A comprehensive academic review of various metal polishing techniques. Referenced at: ScienceDirect

- Practical Machinist Forum - "Techniques for Mirror Polishing Stainless Tube": A community discussion featuring real-world experiences and tips from industry professionals. Referenced at: practicalmachinist.com