Customized Centerless Grinder Company Revolutionizing Precision Machining

In today's manufacturing landscape, precision and efficiency are paramount. One of the most effective solutions for achieving these goals is the use of centerless grinding technology. A customized centerless grinder company specializes in developing machines tailored to the specific needs of businesses, providing them with the opportunity to enhance their production processes and elevate the quality of their output.

Understanding Centerless Grinding

Centerless grinding is a machining process used to remove material from the outer diameters of cylindrical workpieces. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding allows for continuous material removal without the need for fixturing. This process significantly increases productivity and reduces cycle times, making it an attractive option for manufacturers seeking to optimize their operations.

The Importance of Customization

Every manufacturing environment is unique, and so are the challenges they face. A one-size-fits-all approach to centerless grinding can lead to suboptimal results. Customized centerless grinders are designed to accommodate specific dimensions, tolerances, and materials, ensuring that each machine delivers the precise performance required by the user.

A reputable customized centerless grinder company will work closely with clients to understand their needs and design machines that address their specific challenges. This collaboration can lead to innovations that improve grinding efficiency and quality, resulting in better products and increased profitability.

Key Features of Customized Centerless Grinders

Customized centerless grinders can incorporate various features aimed at enhancing their performance

customized centerless grinder company

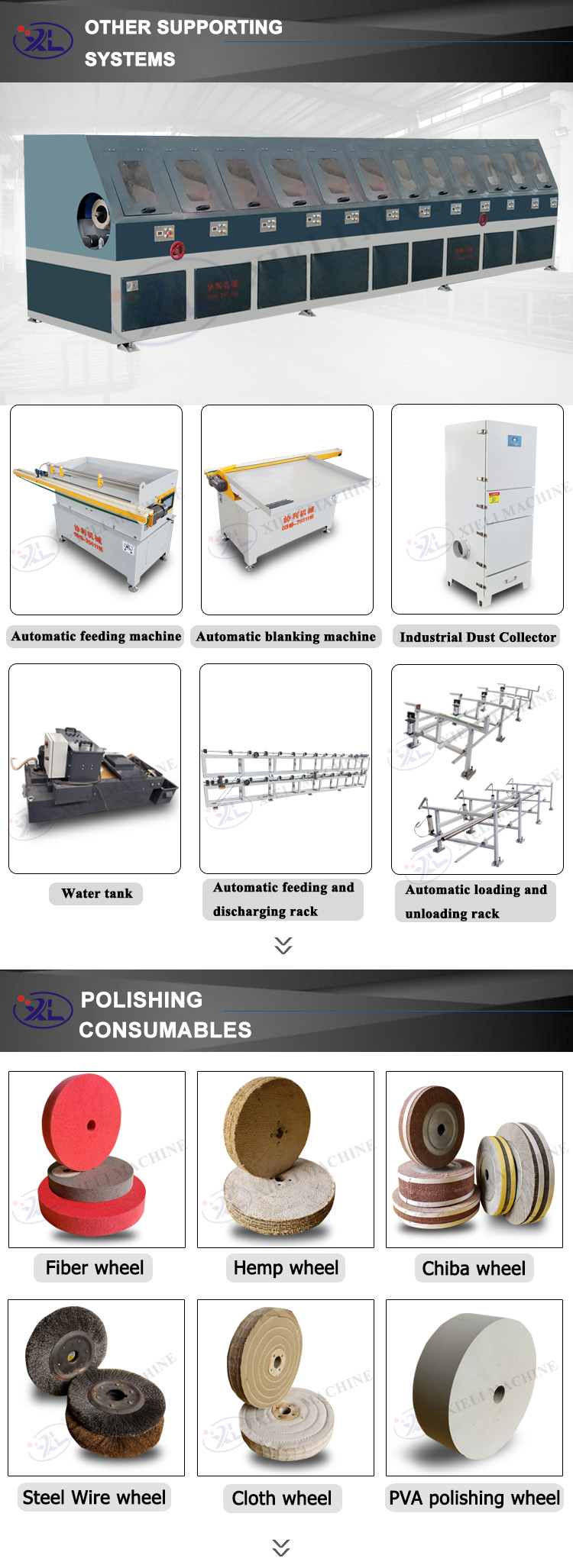

2. Enhanced Automation Integration with robotic systems and automated feeding mechanisms can streamline the manufacturing process, reducing manual labor and improving consistency.

3. Advanced Control Systems Utilizing modern control technology enables precise adjustments and monitoring during the grinding process, ensuring optimal performance and quality control.

4. Tailored Wheel Designs The ability to customize grinding wheels for specific applications and materials enhances the machine's effectiveness and longevity.

5. Cooling and Lubrication Solutions Custom cooling systems can prevent overheating, while tailored lubrication systems reduce wear and extend machine life.

Benefits of Partnering with a Customized Centerless Grinder Company

Investing in a customized centerless grinding solution offers numerous advantages. Companies can improve their production rates, reduce waste, and achieve tighter tolerances. Furthermore, a tailored machine can adapt to changing production requirements, making it a versatile addition to any manufacturing facility.

Moreover, the long-term relationship with a customized centerless grinder company can provide ongoing support, including maintenance, training, and upgrades, ensuring that the machinery keeps pace with evolving industry standards and technological advancements.

Conclusion

In conclusion, the evolving demands of the manufacturing sector necessitate innovative approaches to machining. A customized centerless grinder company stands at the forefront of this revolution, delivering bespoke solutions that enhance precision, efficiency, and productivity. By partnering with such a company, manufacturers can leverage cutting-edge technology tailored to their unique requirements, positioning themselves for success in an increasingly competitive marketplace. With the right tools and partnerships, the future of precision machining is indeed bright.