In the pursuit of enhancing the quality of stainless steel products, utilizing a stainless polishing machine has become an indispensable part of manufacturing and finishing processes. These machines are not only pivotal for enhancing the appearance of stainless steel surfaces but also for increasing their longevity and performance. Drawing from years of expertise, this article delves into the intricate functioning, selection criteria, and the multifaceted benefits of stainless polishing machines, offering both novices and professionals insights into making informed choices.

Stainless polishing machines have radically transformed the metal finishing industry. By automated processes that ensure even the minutest surface of stainless steel is polished to perfection, these machines negate the need for labor-intensive manual polishing. The result is a consistent, mirror-like finish that enhances both the aesthetic appeal and material quality.

Expertise in selecting the appropriate type of polishing machine is crucial. Depending on the size, shape, and finish requirements of the product, one might choose between rotary, belt, or vibratory polishing machines. Rotary machines are renowned for their high-speed, efficiency, and ability to handle large-scale production. In contrast, belt machines excel in achieving a fine finish on flat or slightly curved surfaces. Vibratory machines are excellent for small or intricate items, where a uniform finish is paramount.

Stainless polishing machines operate through various methods, typically involving abrasives and polishing compounds. These components interact with the stainless surface, removing imperfections and producing a high-gloss finish. The choice of abrasive material is key, as it must complement the hardness and end-finish desire of the stainless steel. Abrasives like aluminum oxide and silicon carbide are popular due to their durability and consistent performance across different steel grades.

The authority of stainless polishing machines in the industry is undisputed, with seasoned manufacturers continuously innovating to enhance machine features. Modern polishing machines now offer computer numerical control (CNC) systems, enabling precise control over polishing parameters and ensuring optimal results every time. This technological advancement not only guarantees a superior finish but also minimizes material wastage, aligning with eco-friendly production standards.

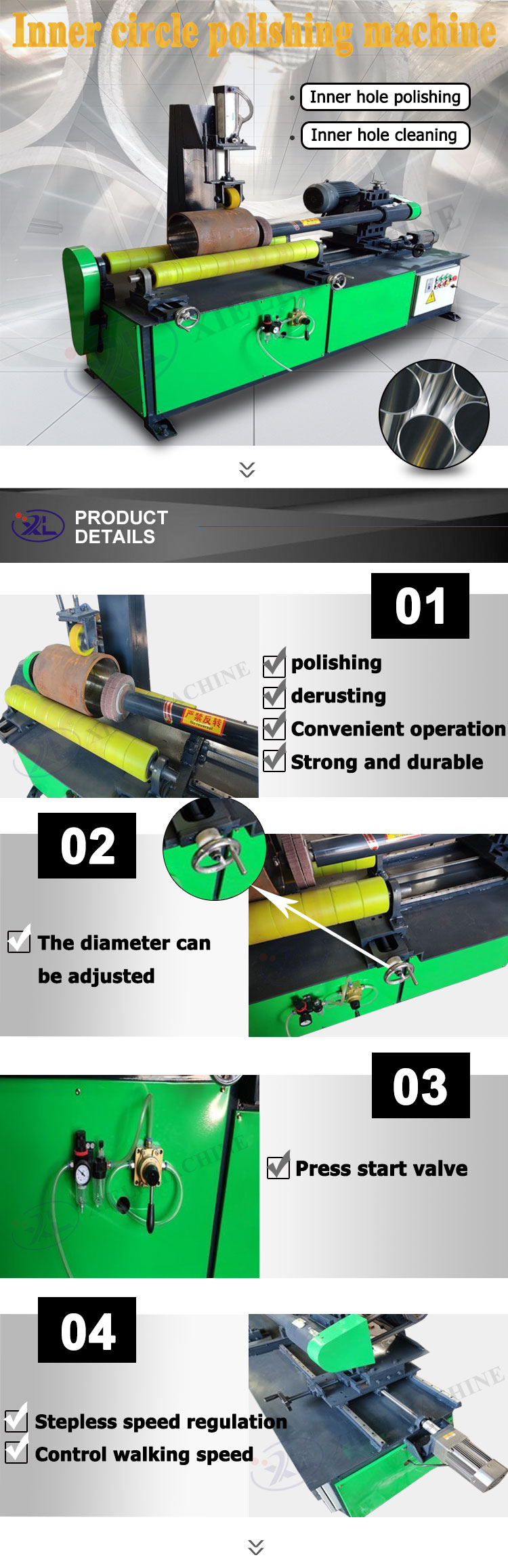

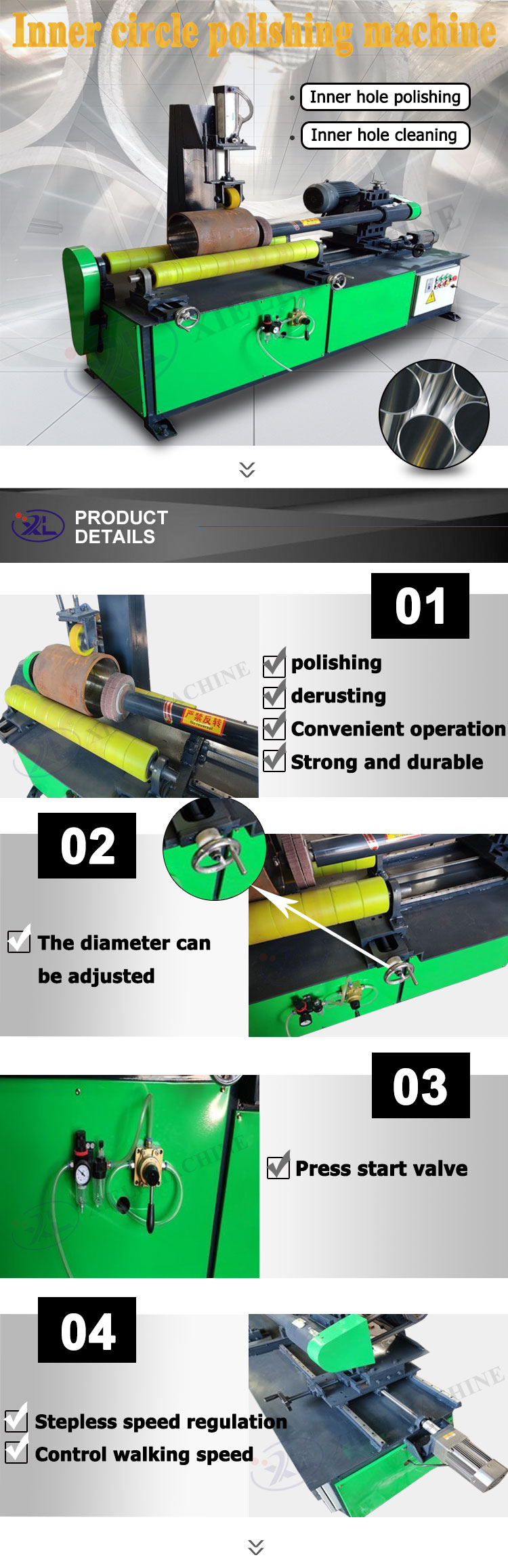

stainless polishing machine product

Trustworthiness in a polishing machine is defined by its build quality and reliability. When selecting the right machine, it's imperative to prioritize brands with a legacy of excellence and a proven track record. Machines constructed from robust materials and equipped with advanced safety features ensure not only prolonged operational life but also safety for the operators.

From an operational standpoint, employing a stainless polishing machine adds immense value to the production cycle. By significantly reducing labor costs and manual effort, these machines allow businesses to allocate resources more efficiently, focusing on innovation and growth. The enhanced finish achieved also reduces the need for post-production polishing or rework, streamlining the overall manufacturing process.

In terms of experience, user-friendliness and maintenance also play a crucial role in the machine's operational lifecycle. Machines designed with intuitive interfaces and easy-to-maintain components allow for seamless integration into existing production lines. Regular maintenance, guided by manufacturer protocols, ensures that the machines function at peak performance, providing consistent results over the long term.

Conclusively, stainless polishing machines represent a synthesis of technological precision and industrial necessity. Their capability to both transform the physical properties of stainless surfaces and reduce operational bottlenecks positions them as a central asset in modern manufacturing. By employing such machines, industries not only enhance the aesthetic quality of their products but also uphold stringent quality standards, catering to the ever-increasing demands of the global market. Making an informed investment in these machines enhances production efficiency and ensures that products meet and exceed customer expectations.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.