The Importance of Buying an Automatic Centerless Grinding Machine

In the world of manufacturing and machining, precision and efficiency are key factors that determine the success of operations. One vital piece of equipment that can significantly enhance these factors is the automatic centerless grinding machine. This article will explore the reasons for investing in such machinery and how it can benefit various industries.

What is an Automatic Centerless Grinding Machine?

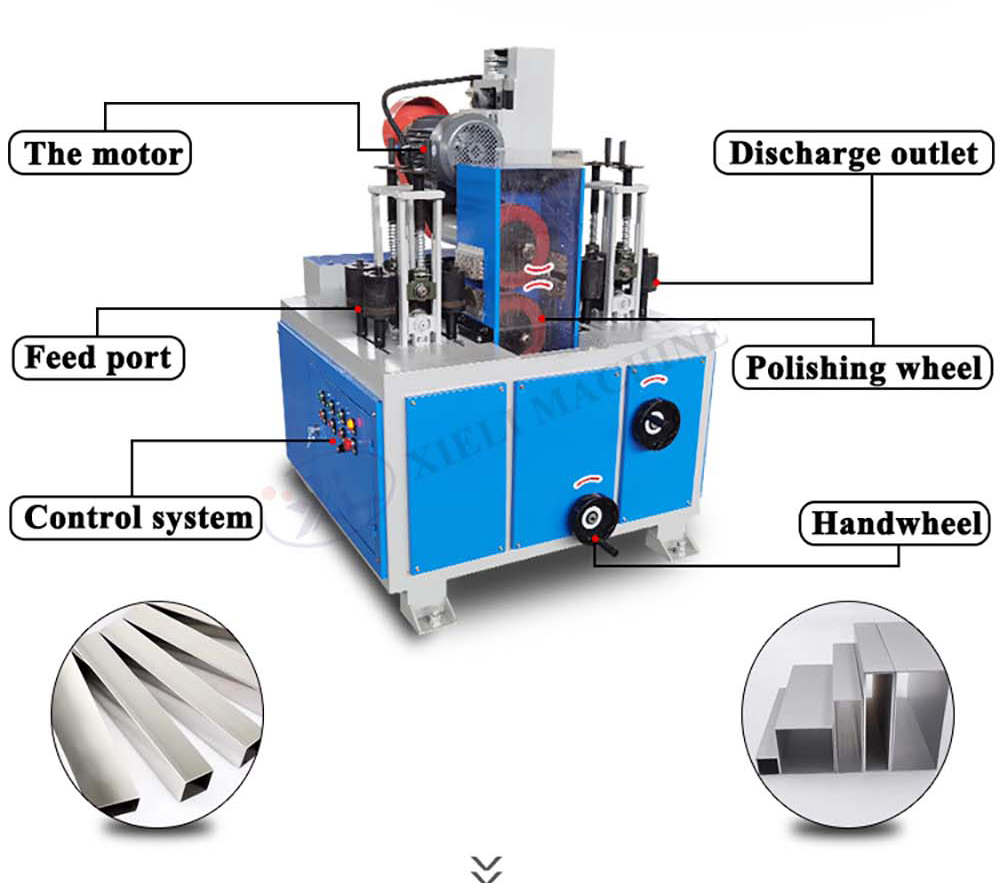

An automatic centerless grinding machine is a specialized piece of equipment designed for grinding cylindrical workpieces without the need for a fixed center point. Unlike traditional grinding machines that require a center to hold the workpiece in place, centerless grinders utilize two rotating wheels—one for grinding and another for regulating the speed of the workpiece. This innovative design allows for continuous operation and increased productivity.

Advantages of Centerless Grinding

1. Increased Efficiency One of the primary advantages of automatic centerless grinding machines is their ability to handle large volumes of workpieces quickly. The automated nature of these machines allows for minimal human intervention, leading to higher throughput rates. As a result, manufacturers can meet increased demand without compromising quality.

2. Enhanced Precision Centerless grinding machines are known for their ability to produce highly precise and consistent results. The lack of a center point eliminates the possibility of workpiece deformation during the grinding process. This precision is essential in industries such as automotive, aerospace, and medical devices, where even the slightest deviation can lead to significant issues.

3. Versatility Automatic centerless grinding machines can accommodate a wide variety of materials and workpiece sizes. They are suitable for grinding metals, plastics, and other materials, making them an excellent investment for manufacturers dealing with diverse product lines. Additionally, the machines can easily adapt to different production requirements, from small batch runs to large-scale manufacturing.

4. Cost Savings While the initial investment in an automatic centerless grinding machine may be substantial, the long-term savings can be significant. The increased efficiency and reduced labor costs contribute to lower operating expenses. Furthermore, the enhanced precision reduces the likelihood of defects, leading to fewer reworks and scrap materials.

buy automatic centerless grinding machine

5. Improved Workplace Safety Automated machines are designed with various safety features that help protect operators. Reducing the need for manual handling also decreases the risk of workplace accidents. By investing in an automatic centerless grinding machine, manufacturers can create a safer working environment for their employees.

Considerations When Buying

When considering the purchase of an automatic centerless grinding machine, several factors should be taken into account

- Specifications and Features Different models may offer varying features, such as CNC capabilities or programmable settings. It's essential to choose a machine that meets the specific needs of your operations.

- Supplier Reputation Research potential suppliers to ensure they have a proven track record for quality and customer support. Investing in a reliable machine from a reputable manufacturer can save time and money in the long run.

- Maintenance and Support Determine what maintenance services are available for the machine. Regular maintenance is crucial to keep the machine running efficiently and to prolong its lifespan.

Conclusion

Investing in an automatic centerless grinding machine can significantly enhance a manufacturer’s capabilities, efficiency, and precision. As industries continue to demand higher quality at faster production rates, such machines are becoming increasingly essential. By carefully considering the features, suppliers, and maintenance options, businesses can make informed decisions that will pay off in operational excellence and profitability.