The Role and Importance of Centerless Grinder Operator Suppliers in Manufacturing

In the rapidly evolving landscape of manufacturing, precision and efficiency are paramount. One of the essential tools contributing to these factors is the centerless grinder. As an indispensable part of the machining process, centerless grinders are designed to provide high-volume production capabilities combined with precise workpiece dimensions. This is where centerless grinder operator suppliers come into play, offering not just the necessary equipment but also a wealth of expertise that enhances manufacturing operations.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is supported by centers, centerless grinding employs a unique configuration again relying on a support wheel and a grinding wheel. The workpiece is fed through the machine and is held in place with the use of friction and kinetic energy. This process allows for continuous production of parts that are uniform in size and finish, making it highly suitable for mass production.

The Supplier's Role

Centerless grinder operator suppliers are not merely vendors of machinery; they are critical partners in the manufacturing process. Their role includes

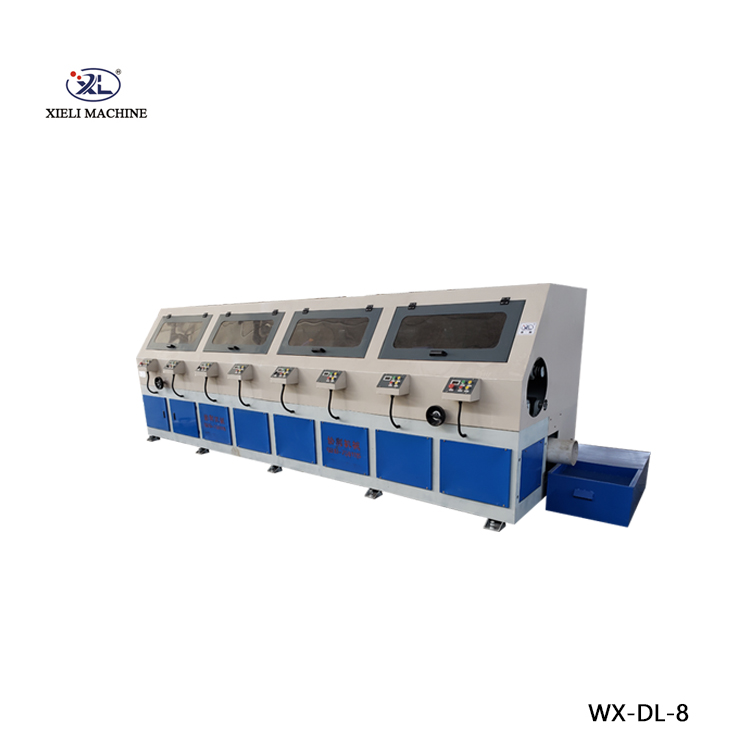

1. Equipment Provision Suppliers offer a variety of centerless grinding machines tailored to different industry needs. These machines differ in specifications, sizes, and capabilities, allowing manufacturers to choose the best fit for their production goals.

2. Technical Support Beyond supplying equipment, these suppliers provide technical support to help operators maximize the efficiency of their machines. This support may include training on machine operation, maintenance, and troubleshooting common issues that could disrupt production.

centerless grinder operator supplier

3. Custom Solutions Many suppliers work closely with manufacturers to develop customized grinding solutions. This can involve modifying existing machines to suit specific production requirements or offering bespoke tooling and fixtures that optimize the grinding process.

4. Parts and Maintenance A reliable supplier also offers spare parts and regular maintenance services. This is crucial for minimizing downtime and ensuring that machines operate at peak performance over their lifespan.

Challenges and Considerations

Choosing the right centerless grinder operator supplier involves careful consideration of various factors. Manufacturers must assess the supplier’s reputation, experience in the industry, and the range of products and services offered. Additionally, it is essential to consider after-sales support and the availability of maintenance services to ensure longevity and efficiency in the grinding process.

The Future of Centerless Grinding

As manufacturing technologies continue to advance, the role of centerless grinder operator suppliers will evolve. Automation and digitalization are becoming increasingly significant, leading to the development of smart grinding solutions that integrate machine learning and data analytics. This means that suppliers must not only provide traditional grinding machines but also embrace technological advancements that enhance productivity and quality.

In conclusion, centerless grinder operator suppliers are vital players in the manufacturing sector, providing essential equipment and expertise that enable companies to achieve precision in their machining processes. By offering comprehensive support, customized solutions, and a focus on innovation, these suppliers contribute significantly to the efficiency and effectiveness of manufacturing operations worldwide. As the industry continues to advance and adapt, the relationship between manufacturers and their suppliers will be crucial in navigating future challenges and opportunities.