Centerless grinder blades are a vital component in the manufacturing industry, often overshadowed by the machines they empower. Yet, their role is indispensable when it comes to precision and efficiency in the grinding process. This article delves into the nuances of centerless grinder blades, bringing insights from industry veterans who have honed their skills over decades, to help you understand why these products deserve your attention.

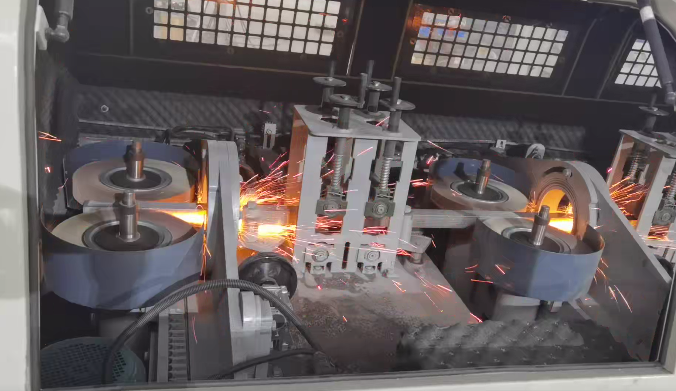

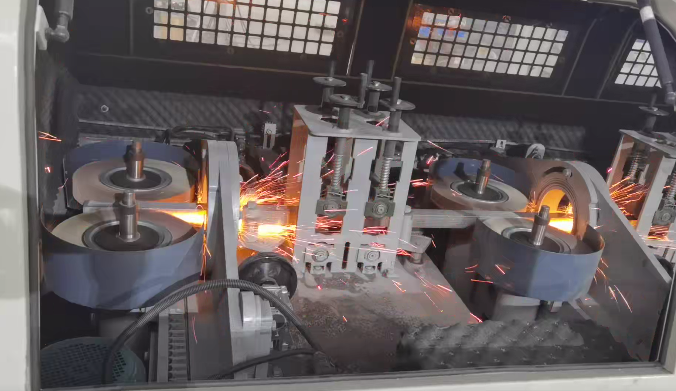

In the world of machining and manufacturing, precision is king. Centerless grinder blades fit into this realm by providing unparalleled precision and consistency. As the name 'centerless' suggests, these blades are used in centerless grinding processes which do not rely on centers to hold the workpiece in place. Instead, the workpiece is held between a rotating grinding wheel and a stationary blade, known as the work blade.

One of the remarkable characteristics of these grinder blades is their ability to enhance operational efficiency. Experienced operators highlight that the right blade geometry and material can improve the throughput rate significantly. With the correct setup, operators have reported an increase in machine productivity by up to 30%, demonstrating the value of investing time in understanding the best blade for each application.

The choice of material for centerless grinder blades is crucial. It directly impacts the grinding process's outcome and the lifespan of the blade itself. Common materials include high-speed steel (HSS), carbide, and ceramics. Each material offers unique benefits. For instance, carbide blades are renowned for their durability and wear resistance, making them ideal for high-volume production settings. On the other hand, HSS blades might be preferred in scenarios where flexibility and ease of reshaping are required, catering to bespoke or variable manufacturing needs.

The expertise required in selecting and maintaining these blades cannot be overstated. Industry experts emphasize the need for routine maintenance and precise adjustments to the blade settings to achieve optimal results. A well-maintained blade not only extends the life of the equipment but also ensures the quality of the final product, effectively reducing waste and rework.

Ensuring high standards of quality control is another critical aspect emphasized by authoritative figures in the industry. Every blade must undergo rigorous testing to meet specific dimensional tolerances and hardness criteria. Such stringent quality checks are vital because even the slightest deviation could lead to significant defects in the workpiece, underlining the intensive nature of producing these precision tools.

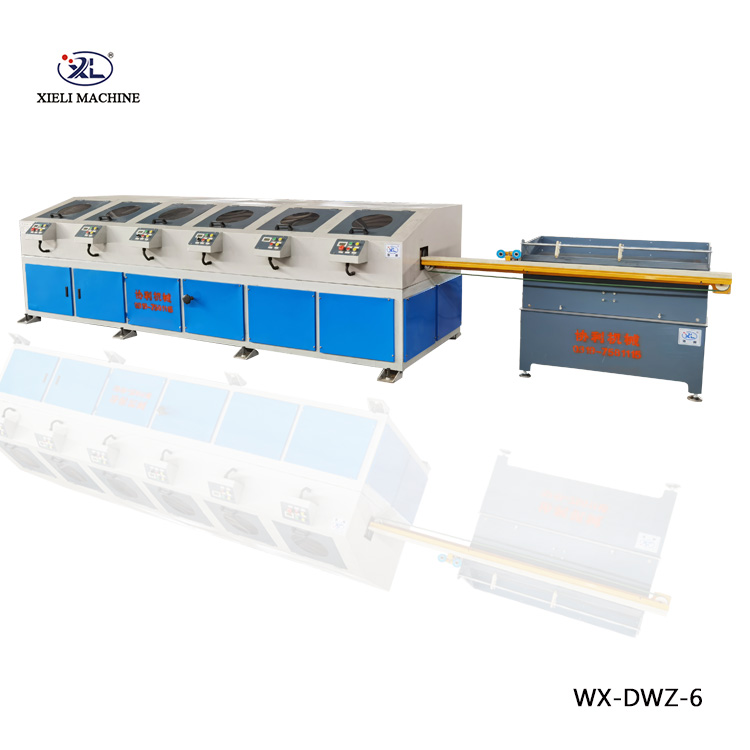

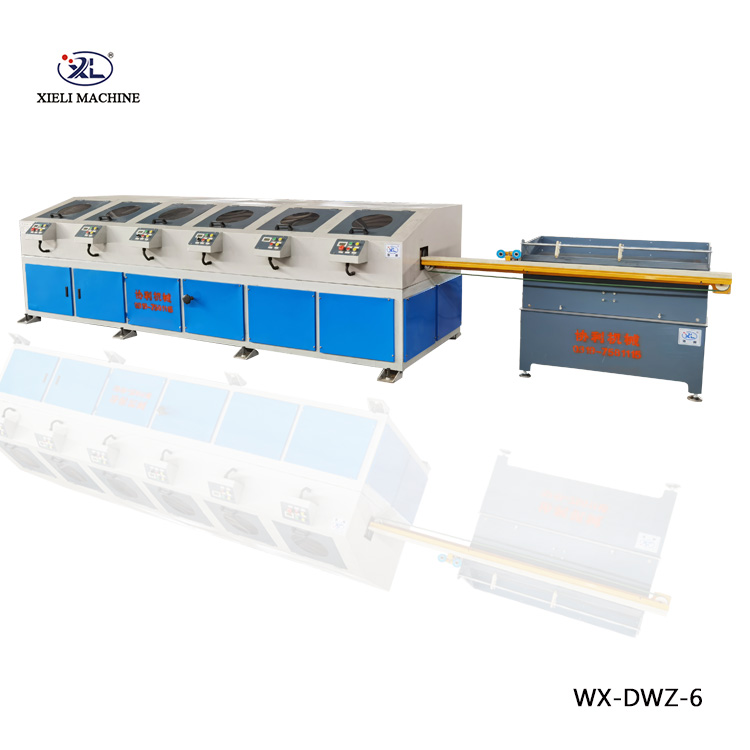

centerless grinder blades products

Trust in the manufacturers is an additional vector worth exploring. Leading brands in the centerless grinder blade market often have decades of experience and a robust track record, providing peace of mind to their customers. Certifications from industry bodies and adherence to international quality standards further reinforce trust. For buyers, aligning with such reputable brands ensures they receive products that have been tried and trusted across various applications globally.

Networking within the industry can also help in understanding the latest advancements and sharing best practices related to centerless grinder blades. Attending trade shows and seminars, or participating in online forums, can provide invaluable insights and updates on newer materials, coatings, and technologies that could improve operational efficiencies or extend the tool's lifespan.

The successful implementation of centerless grinder blades involves a confluence of experience, specialized knowledge, and a commitment to continuous learning and improvement. Whether you're an operator on the floor or an executive overseeing manufacturing processes, understanding the intricacies of these blades can provide a significant competitive edge.

In a market swamped with products claiming to be the best, identifying genuine quality requires education and awareness. Investing in high-quality centerless grinder blades might seem costly at the outset, but the returns in terms of durability, efficiency, and quality assurance make it an investment well worth considering for any serious manufacturer.

To sum up, the world of centerless grinder blades goes beyond mere components—they are enablers of precision and catalysts of efficiency. An admiration for their intricate design and functionality offers a glimpse into the complex dance of science and engineering that drives modern manufacturing processes.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.