The Rise of Multi-Head Automatic Polishing Machine Factories

In the world of manufacturing, efficiency and precision are paramount. As industries strive to enhance productivity while maintaining high quality, the demand for advanced machinery increases. One significant innovation that has emerged is the multi-head automatic polishing machine, which has revolutionized the polishing process across various sectors. This article delves into the pivotal role of multi-head automatic polishing machine factories and their contributions to modern manufacturing.

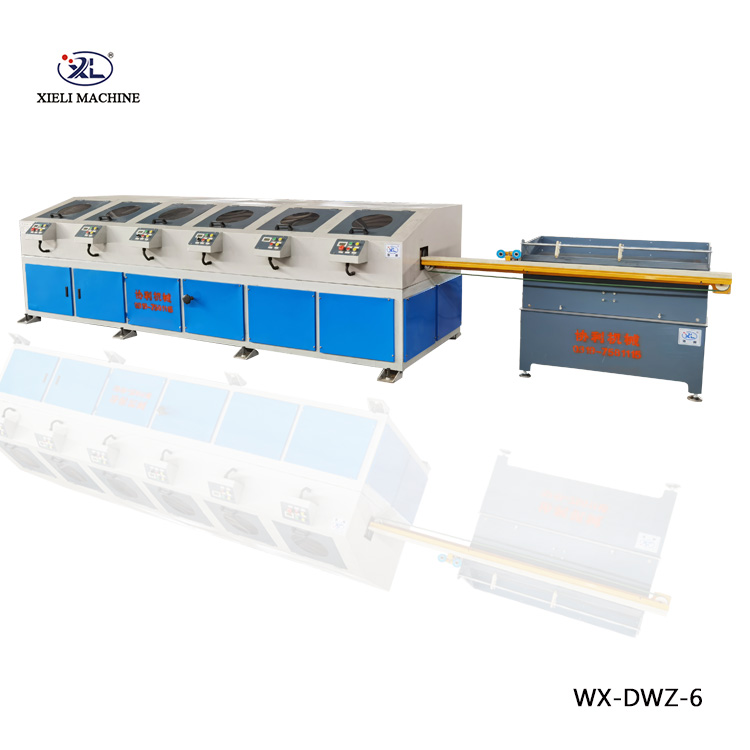

Multi-head automatic polishing machines are designed to streamline the polishing process by utilizing multiple polishing heads that operate simultaneously. This capability allows manufacturers to process more items in a shorter period, significantly boosting productivity. In industries such as automotive, aerospace, and electronics, where precision and finish are critical, these machines are indispensable.

The factories that produce these sophisticated machines focus on integrating advanced technologies, such as artificial intelligence and automation. By incorporating programmable logic controllers (PLCs) and computer numerical control (CNC), these machines can execute complex polishing patterns with minimal human intervention. This not only improves the consistency of the finish but also reduces the risk of human error, which can lead to costly defects.

multi-head automatic polishing machine factories

Moreover, multi-head automatic polishing machine factories prioritize the use of high-quality materials and components in their production processes. The longevity and reliability of these machines are essential for manufacturers who rely on them for continuous operation. Therefore, factories invest in research and development to enhance the durability and efficiency of their products. Innovations in polishing materials, such as high-performance abrasives, also contribute to achieving superior results.

The versatility of these machines is another factor that contributes to their growing popularity. Multi-head automatic polishing machines can be adapted for various materials, including metals, plastics, and composites. This adaptability makes them suitable for a wide range of applications, from finishing intricate components in medical devices to polishing large automotive parts. As industries evolve and diversify, the need for flexible manufacturing solutions becomes increasingly important, solidifying the position of these machines in the market.

In addition to enhancing productivity, multi-head automatic polishing machines also align with sustainability efforts. Many factories are now designing machines that consume less energy and generate less waste. By focusing on eco-friendly practices, manufacturers can reduce their carbon footprint and meet the growing demand for sustainable production methods.

In conclusion, multi-head automatic polishing machine factories play a critical role in the modern manufacturing landscape. By offering innovative, efficient, and flexible solutions, they cater to the evolving needs of various industries. As technology continues to advance, these factories are likely to lead the way in developing even more sophisticated polishing machines that not only enhance productivity but also contribute to sustainable manufacturing practices. In an increasingly competitive global market, the integration of these machines will be essential for businesses aiming to stay ahead.