Custom Inner Wall Polishing Machines Revolutionizing Surface Finishing

In today's fast-paced manufacturing world, the demand for high-quality surface finishes has never been greater. Industries ranging from aerospace to automotive and beyond rely on precision-engineered components that not only meet stringent performance standards but also aesthetics. One critical aspect of this is the inner wall finishing of various components, which is where custom inner wall polishing machines come into play.

A custom inner wall polishing machine is designed specifically to enhance the surface finish of cylindrical components, such as pipes, tubes, and tanks. These machines are tailored to meet the unique requirements of various materials, shapes, and sizes, providing a level of flexibility that standard machines often cannot achieve. By employing innovative polishing techniques, they ensure a smooth, uniform finish on the inner walls, which can significantly impact the overall performance and longevity of the product.

One of the primary advantages of using a custom inner wall polishing machine is the ability to achieve tight tolerances and superior finishes. The technology involved in these machines often includes advanced features such as automated polishing heads, adjustable speeds, and customizable abrasive materials. This allows manufacturers to fine-tune the polishing process to suit specific applications, whether it is reducing friction in hydraulic systems or improving the cleanliness of pharmaceutical components.

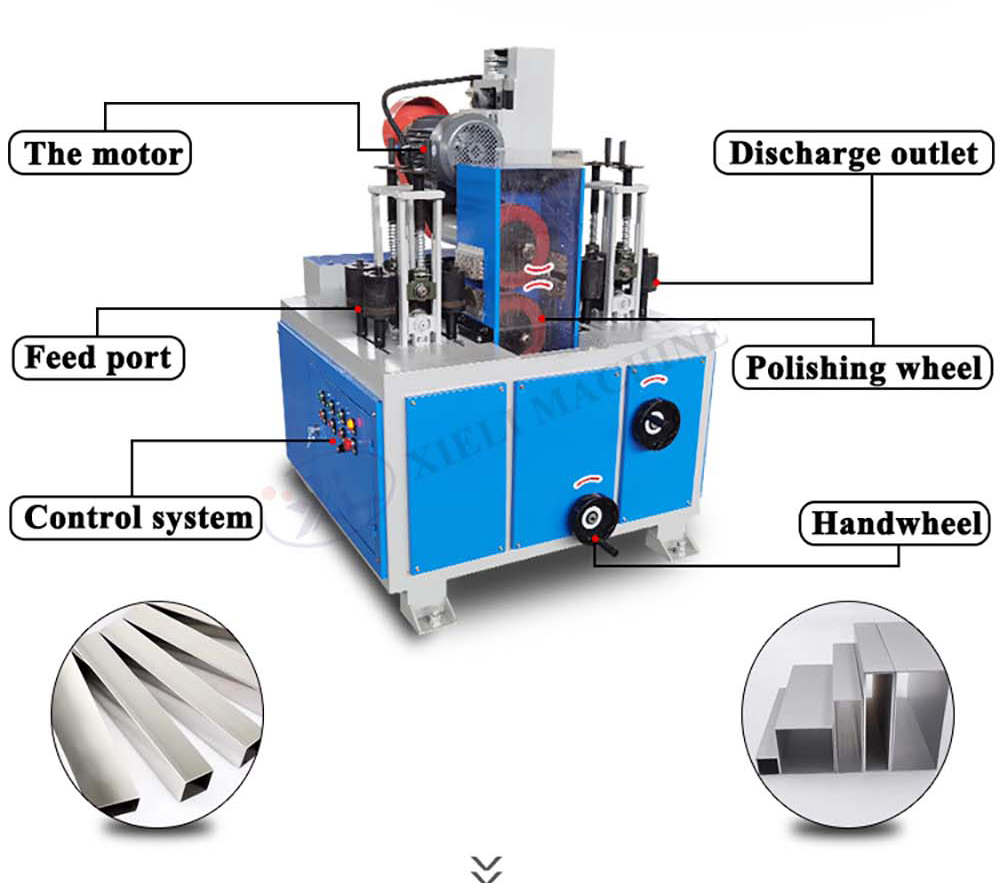

custom inner wall polishing machine

Moreover, custom inner wall polishing machines are designed with energy efficiency and waste reduction in mind. Many modern machines incorporate features that minimize material wastage and optimize polishing media usage. This is not only environmentally sustainable but also economical for manufacturers. By streamlining the polishing process, companies can reduce production times and costs while maintaining high quality standards.

In addition to technical advancements, the rise of Industry 4.0 has prompted the integration of smart technologies into polishing machines. Many custom inner wall polishing machines now come equipped with IoT (Internet of Things) capabilities, enabling real-time monitoring and data analytics. This connectivity allows for predictive maintenance, better process control, and enhanced traceability, ensuring that the polishing operation is as efficient and effective as possible.

Furthermore, the versatility of these machines allows them to cater to a wide range of industries. From precision automotive parts to intricate aerospace components, the ability to customize polishing solutions makes these machines invaluable. They can handle different materials, including metals, plastics, and composites, without compromising the quality of the finish.

In conclusion, custom inner wall polishing machines are at the forefront of surface finishing technology, enabling manufacturers to achieve impeccable results tailored to their specific needs. With their ability to enhance performance, reduce waste, and integrate smart technologies, these machines are revolutionizing the way industries approach inner wall polishing. As the demand for high-quality finishes continues to grow, investing in custom inner wall polishing solutions will undoubtedly pay dividends in terms of product quality and operational efficiency. The future of manufacturing looks brighter with these advanced polishing technologies paving the way for excellence in surface finishing.