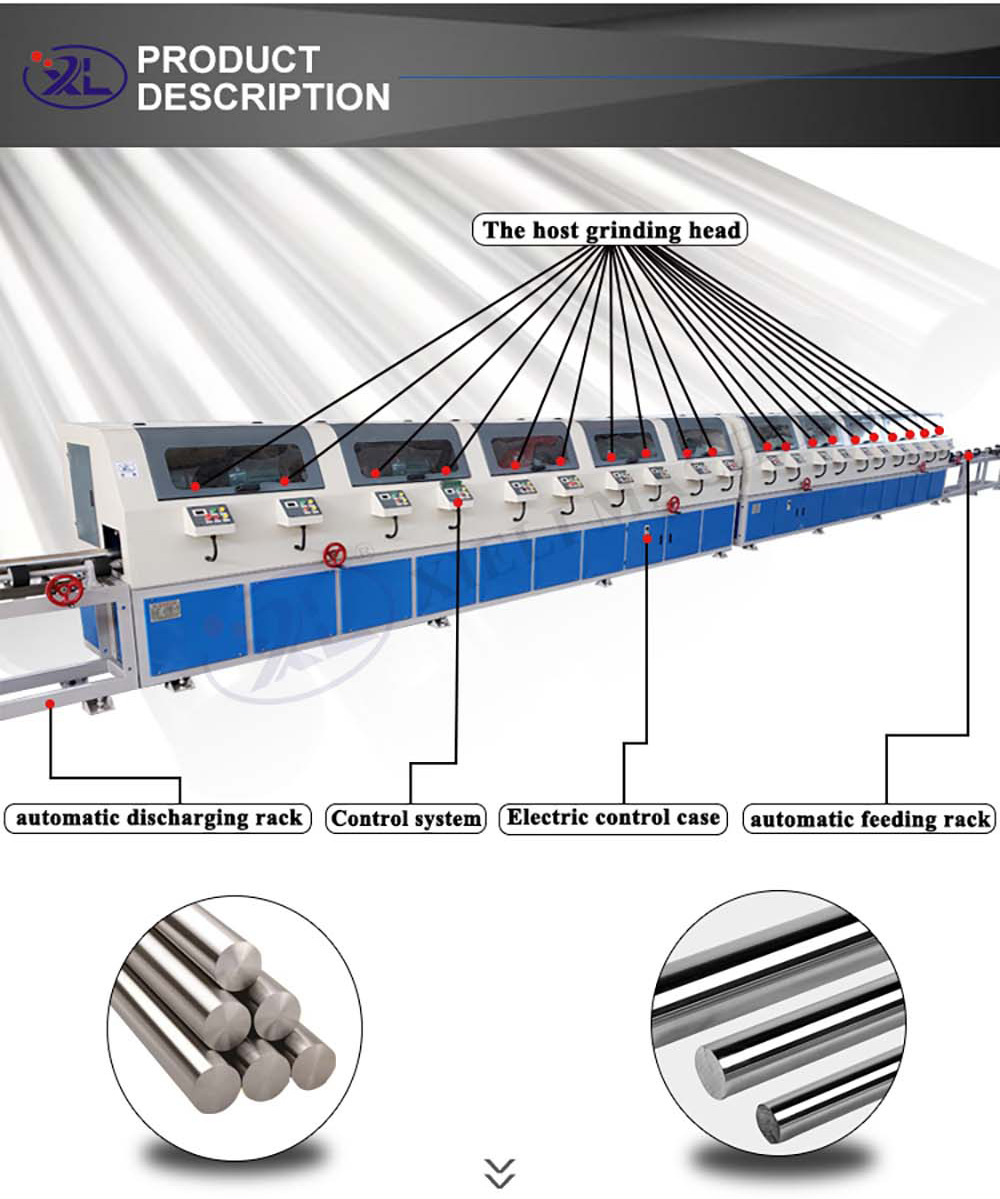

WX-DLZ Series Multi-station Vertical Polishing Machine: Precision Rust Removal and Polishing for Industrial Applications

The WX-DLZ Series Multi-station Vertical Polishing Machine is a cutting-edge solution designed for efficient rust removal and polishing of round pipes, rods, and slender shafts across multiple industries. This advanced machinery combines automation, precision engineering, and customizable features to meet the demands of modern manufacturing. Below, we explore its core functionalities, technical specifications, applications, and the reputable company behind it.

Product Overview: Revolutionizing Metal Surface Treatment

The WX-DLZ Series is a specialized round pipe polishing machine engineered to address the challenges of rust removal, surface refinement, and polishing for materials such as steel, stainless steel, and other metallic components. Its design prioritizes efficiency, durability, and adaptability, making it a preferred choice for industries like automotive, hydraulic systems, and machinery manufacturing.

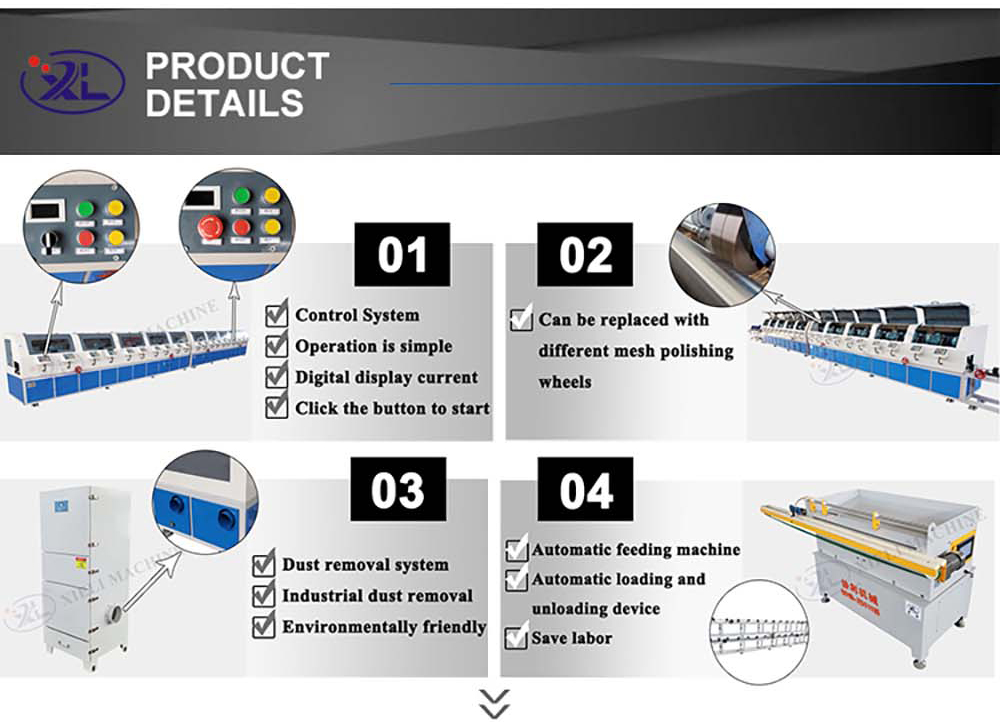

Key features include:

- Multi-station operation: Enables simultaneous processing of multiple parts, enhancing productivity.

- Automatic loading and unloading: Reduces manual intervention, ensuring consistent quality and safety.

- Customizable polishing wheels: Supports a range of materials, including Chiba wheels, nylon wheels, and PVA, to suit diverse applications.

- Stepless speed control: Allows precise adjustment of the guide wheel speed for optimal performance.

Technical Specifications: Precision and Performance

The WX-DLZ Series offers a range of models (WX-DLZ-2, WX-DLZ-4, WX-DLZ-6, WX-DLZ-8, WX-DLZ-10) tailored to varying production needs. Below is a detailed specification table:

| Project | Model | WX-DLZ-2 | WX-DLZ-4 | WX-DLZ-6 | WX-DLZ-8 | WX-DLZ-10 |

|---|---|---|---|---|---|---|

| Input Voltage (V) | 380V (Three phase four wire) | |||||

| Input Power (kW) | 8.6 | 18 | 26.5 | 35.5 | 44 | |

| Polishing Wheel Specification (mm) | 250/300*40/50*32 (Width can be assembled) | |||||

| Guide Wheel Specification (mm) | 110*70 | |||||

| Polishing Wheel Speed (r/min) | 3000 | |||||

| Guide Wheel Speed (r/min) | Stepless speed regulation | |||||

| Machining Diameter (mm) | 10-150 | |||||

| Processing Efficiency (m/min) | 0-8 | |||||

| Surface Roughness (μm) | Ra 0.02 | |||||

| Processing Length (mm) | 300-9000 | |||||

| Wet Water Cycle Dust Removal | Optional | |||||

| Dry Fan Dust Removal | Optional | |||||

| Grinding Head Feeding Mode | Digital display electric adjustable | |||||

| Passive Guide Wheel Adjustment Method | Manual/electric/automatic (optional) | |||||

| Machine Tool Total Weight (kg) | 800 | 1600 | 2400 | 3200 | 4000 | |

| Equipment Dimension (L x W x H, mm) | 1.4*1.2*1.4 | 2.6*1.2*1.4 | 3.8*1.2*1.4 | 5.0*1.2*1.4 | 6.2*1.2*1.4 | |

Applications: Versatile Solutions for Diverse Industries

The WX-DLZ Series is designed to cater to a wide array of industrial applications. Its adaptability makes it a valuable asset in:

- Hardware Manufacturing: Polishing of components like nuts, bolts, and fittings.

- Vehicle Accessories: Surface treatment of automotive parts such as exhaust pipes and suspension components.

- Hydraulic Cylinders: Ensuring smooth, rust-free surfaces for optimal performance.

- Steel and Wood Furniture: Enhancing the finish of metal frames and decorative elements.

- Instrument Machinery: Precision polishing of delicate mechanical parts.

- Standard Parts: Consistent quality for mass-produced components.

With its ability to handle diameters ranging from 10mm to 150mm and lengths up to 9000mm, the machine is ideal for both small-scale and large-scale production environments.

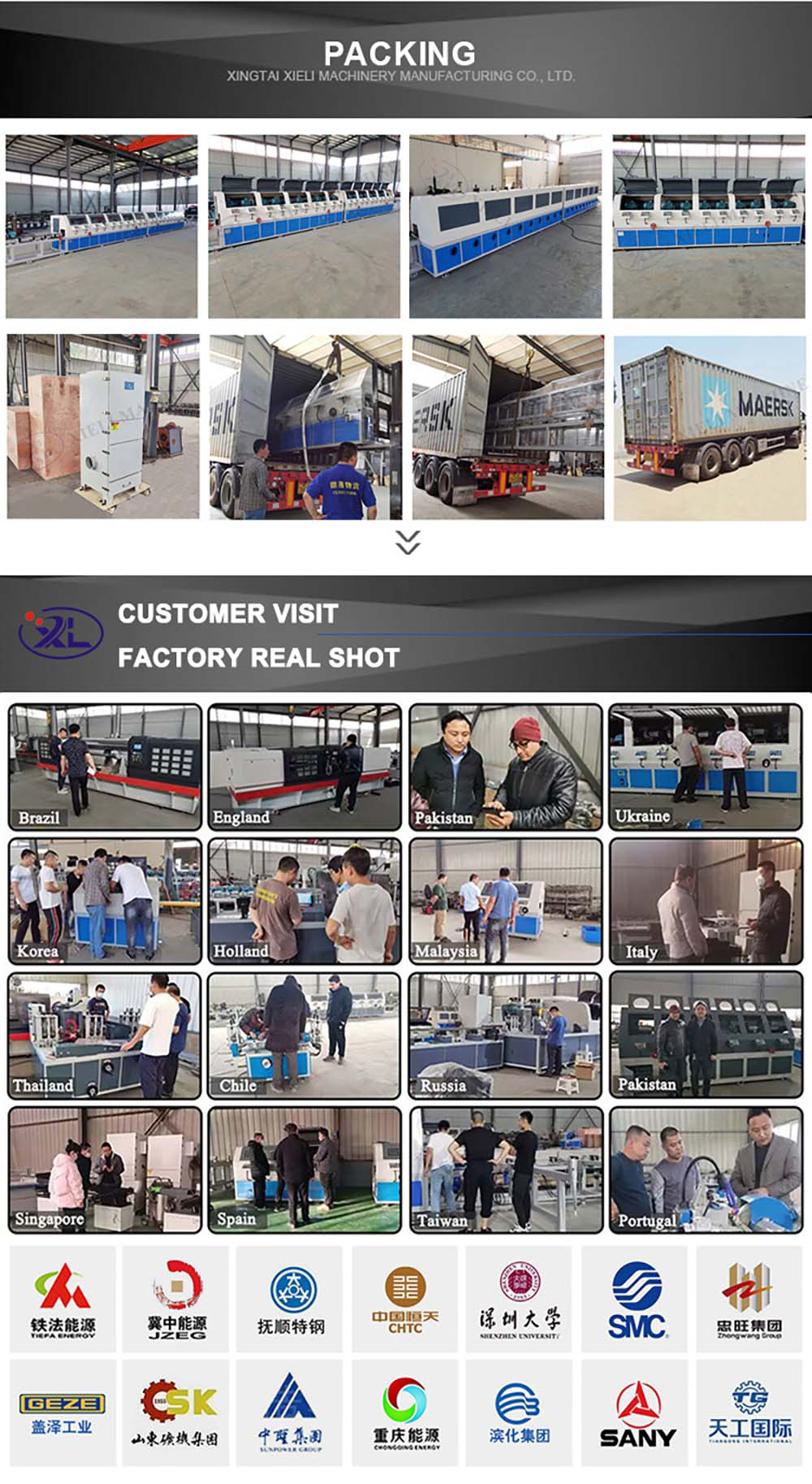

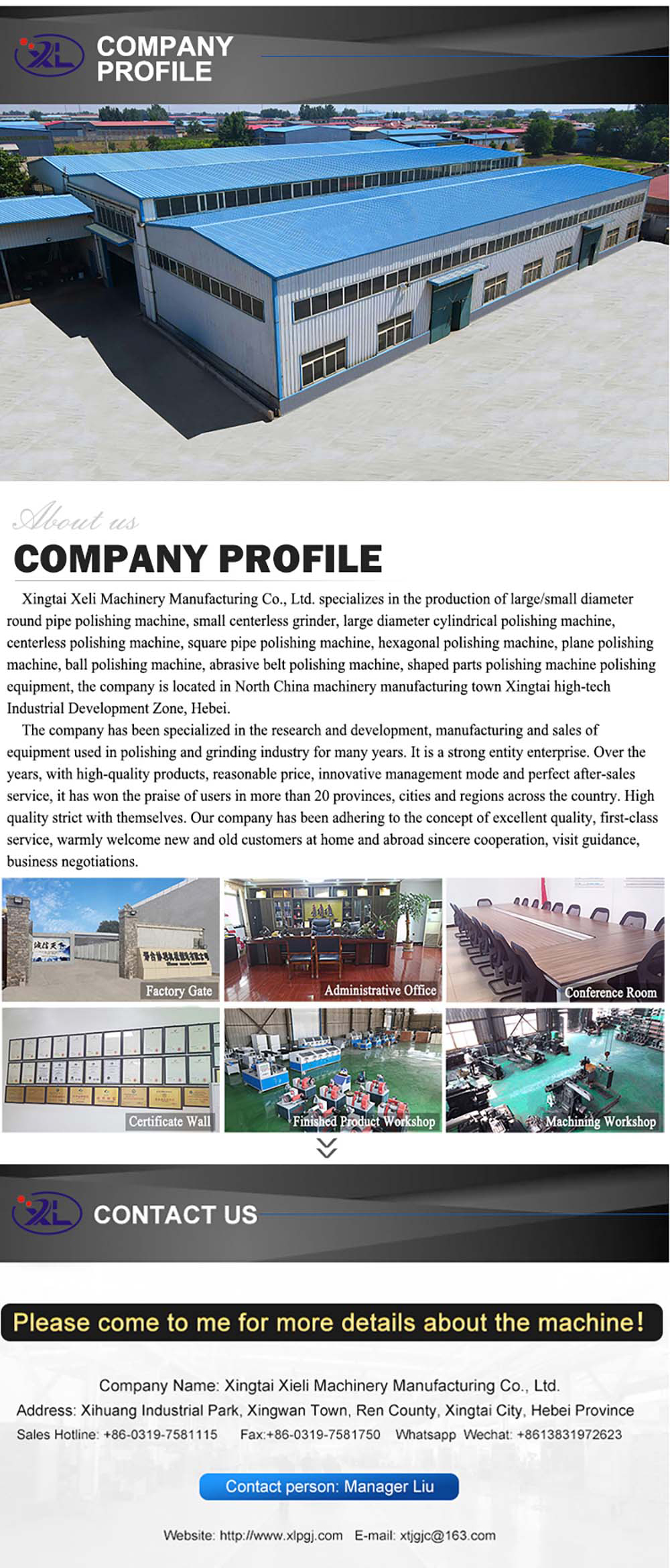

Company Background: Xingtai Xieli Machinery Manufacturing Co., Ltd.

Manufactured by Xingtai Xieli Machinery Manufacturing Co., Ltd., the WX-DLZ Series reflects the company's commitment to innovation and quality. With over a decade of experience in the industrial machinery sector, Xingtai Xieli has established itself as a trusted provider of advanced solutions for metal processing and surface treatment.

The company's dedication to precision engineering and customer-centric design ensures that its products meet the highest standards of performance and reliability. Their website offers further insights into their product range and technical support services.

Key Advantages: Why Choose the WX-DLZ Series?

The WX-DLZ Series stands out due to its unique features and benefits:

- High Automation: The automatic loading and unloading rack minimizes manual labor, reducing costs and improving efficiency.

- Reliability and Stability: Advanced design and high-quality materials ensure long-term performance even under demanding conditions.

- Flexibility: Customizable configurations allow the machine to adapt to different materials and processing requirements.

- Environmental Compliance: Optional wet/dry dust removal systems reduce workplace pollution, aligning with modern safety standards.

For more details on the WX-DLZ Series, visit the product page.

Working Principle: Seamless Integration of Automation and Precision

The WX-DLZ Series operates through a streamlined process:

- Feeding: The automatic loading and unloading rack positions the workpiece for processing.

- Processing: The polishing machine performs the operation, guided by precise speed control and digital adjustments.

- Discharge: The finished part is automatically unloaded, ensuring a continuous workflow.

This automation not only enhances productivity but also ensures consistent quality, as highlighted by NIST (National Institute of Standards and Technology) in its research on industrial automation standards.

Conclusion: A Reliable Partner for Industrial Surface Treatment

The WX-DLZ Series Multi-station Vertical Polishing Machine is a testament to Xingtai Xieli Machinery Manufacturing Co., Ltd.'s expertise in delivering innovative, high-performance solutions. Its combination of automation, precision, and adaptability makes it an essential tool for industries requiring efficient rust removal and polishing. Whether for small-scale operations or large manufacturing lines, this machine sets a new benchmark in surface treatment technology.

For further information, explore the company website or contact their sales team directly.

References

National Institute of Standards and Technology (NIST). "Driving Innovation Through Measurement Science." Retrieved from https://www.nist.gov.