Embracing Efficiency The Importance of Wholesale Junker Centerless Grinders in Modern Manufacturing

In today's fast-paced manufacturing landscape, companies are continually seeking innovations that streamline processes and enhance productivity. One such innovation is the centerless grinder, a machine that has revolutionized the way manufacturers achieve precision and efficiency in grinding operations. Among the leading brands in this domain, Junker has established itself as a benchmark for quality and performance, particularly when it comes to wholesale offerings.

Centerless grinding is a process that allows for the grinding of cylindrical parts without the need for a traditional workholding fixture. This method creates a more efficient workflow, as it enables the continuous production of precision components. The Junker centerless grinder stands out for its ability to produce high-quality, consistent results while minimizing the setup time needed between runs. This capability is particularly valuable in high-volume manufacturing environments where time and cost savings directly impact profitability.

Embracing Efficiency The Importance of Wholesale Junker Centerless Grinders in Modern Manufacturing

One of the key advantages of using a Junker centerless grinder is its advanced automation features. Modern models are equipped with state-of-the-art controls that allow for real-time monitoring and adjustments. This essential capability ensures that the grinding process remains consistent, while also significantly reducing the likelihood of human error. The result is a production line that operates smoothly and efficiently, improving overall output and reducing waste.

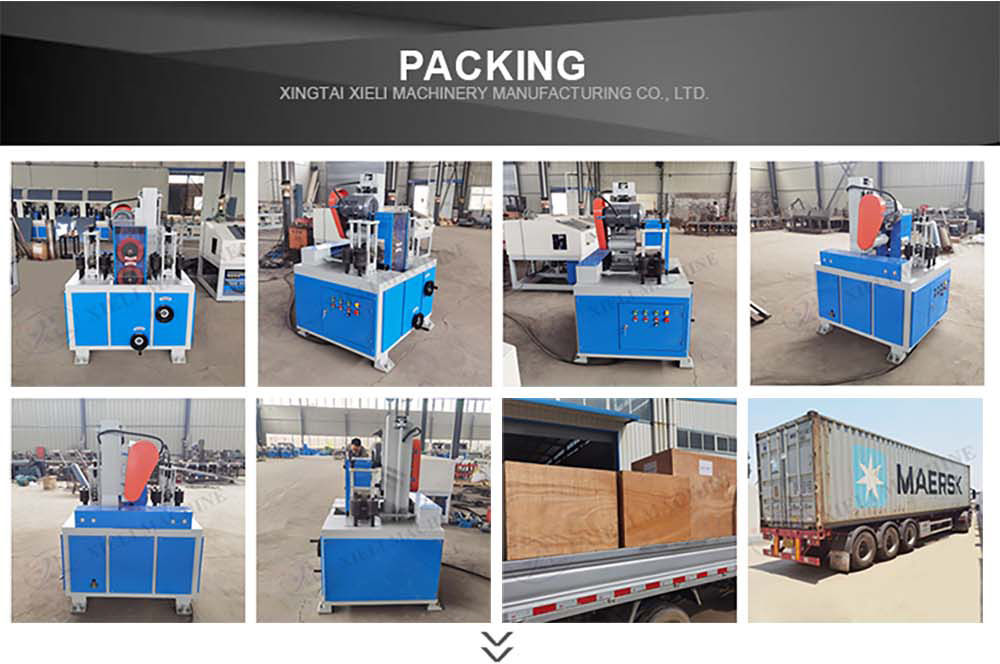

wholesale junker centerless grinder

Moreover, Junker grinders are designed with durability in mind, capable of withstanding the rigorous demands of daily operations. Their robust construction not only ensures longevity, reducing the frequency of machine downtime and maintenance costs, but also guarantees that manufacturers can consistently produce parts to exact specifications.

In addition, the centerless grinding process is known for its flexibility. Junker machines can accommodate a variety of materials and dimensions, making them suitable for diverse applications—from automotive to aerospace parts. This versatility allows manufacturers to adapt quickly to changing market needs, keeping them agile and competitive.

As industries across the globe continue to evolve, the importance of efficient manufacturing processes cannot be overstated. Investing in wholesale Junker centerless grinders is more than just a purchase; it is a strategic move toward enhancing operational efficiency, reducing costs, and improving product quality. By incorporating these advanced machines into their production lines, companies can ensure that they are not only meeting but exceeding the expectations of their customers in an increasingly demanding market.

In conclusion, the wholesale acquisition of Junker centerless grinders represents a vital step for any manufacturer aiming to thrive in today’s competitive environment. With their proven performance, durability, and efficiency, these machines embody the future of manufacturing, paving the way for innovation and growth.