The Importance of Centerless Grinding in Wholesale Manufacturing

In the competitive landscape of wholesale manufacturing, precision and efficiency are paramount. Among the various processes that contribute to high-quality production, centerless grinding stands out as a vital technique, particularly when it comes to achieving uniformity and precision in workpieces. At the heart of this process is the wholesale paragon centerless grinder, a machine that plays an essential role in the manufacturing of numerous components across diverse industries.

What is Centerless Grinding?

Centerless grinding is a method of removing material from the outside diameter of a workpiece. Unlike traditional grinding machines, where the workpiece is held between two centers, centerless grinders hold the workpiece with a support blade and utilize two rotating wheels. This makes it possible to grind the workpiece without having it held at both ends, resulting in increased speed and efficiency.

Advantages of Using Wholesale Paragon Centerless Grinders

1. High Precision and Consistency One of the standout features of paragon centerless grinders is their ability to produce parts with tight tolerances. In wholesale manufacturing, consistency is key, as even the slightest deviation can lead to significant issues in the assembly line. These grinders ensure that every product meets the necessary specifications, maintaining quality throughout large production runs.

2. Increased Production Speed The design of centerless grinders allows for faster material removal compared to traditional grinding methods. This speed not only accelerates the manufacturing process but also contributes to lower production costs, as more parts can be processed in a given timeframe.

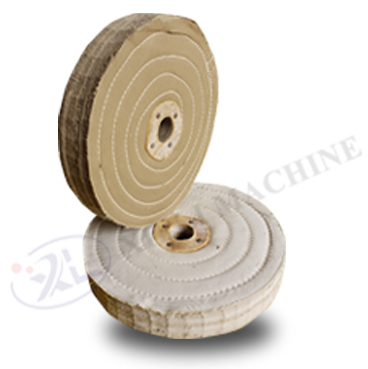

wholesale paragon centerless grinder

3. Versatile Applications Wholesale paragon centerless grinders are adaptable to a variety of materials and sizes, making them suitable for different applications. They can be used to grind a wide range of materials, including metals, plastics, and ceramics, which makes them indispensable in industries such as automotive, aerospace, and medical manufacturing.

4. Reduced Setup Time Compared to conventional grinding machines, centerless grinders require less time for setup and changeover. This reduction in setup time maximizes productivity and allows manufacturers to respond quicker to changing market demands.

5. Improved Surface Finish The grinding process not only shapes the workpiece but also enhances its surface quality. Paragon centerless grinders are designed to achieve a superior surface finish, which is crucial in applications where aesthetic appearance and functional performance are interconnected.

Conclusion

As wholesale manufacturing continues to evolve, the significance of advanced machining processes like centerless grinding cannot be overstated. The wholesale paragon centerless grinder exemplifies the attributes needed for high-volume production precision, speed, and adaptability. By investing in such technology, manufacturers can ensure they remain competitive in a global market, meeting both quality and efficiency standards.

In conclusion, embracing the capabilities of centerless grinding, and specifically the wholesale paragon centerless grinder, can lead to enhanced manufacturing processes that yield superior products while maintaining operational effectiveness. For businesses looking to excel in today’s fast-paced industrial environment, capitalizing on these advanced grinding solutions is a smart and strategic move.