Wholesale Centerless Grinder Wheels The Key to Precision Manufacturing

In the world of precision manufacturing, achieving high-quality finishes and maintaining tight tolerances are paramount. Centerless grinding has emerged as a revolutionary process in the machining industry, offering exceptional efficiency and precision. Central to the success of this method is the use of high-quality centerless grinder wheels. For manufacturers looking to optimize their operations, understanding the importance of wholesale centerless grinder wheels can be a game changer.

Centerless grinding is uniquely advantageous because it allows for the continuous processing of workpieces without requiring the complexities of part fixturing. The process involves placing the workpiece between two wheels a grinding wheel that removes material and a regulating wheel that controls the speed and rotation of the workpiece. The synergy between these two components is critical, and the quality of the grinding wheels plays an essential role in the overall performance of the machine.

Wholesale centerless grinder wheels provide manufacturers with a cost-effective solution for acquiring high-quality grinding wheels needed for their operations. Purchasing in bulk leads to significant savings, allowing businesses to reduce operational costs while ensuring that they have a reliable supply of wheels to keep production moving smoothly.

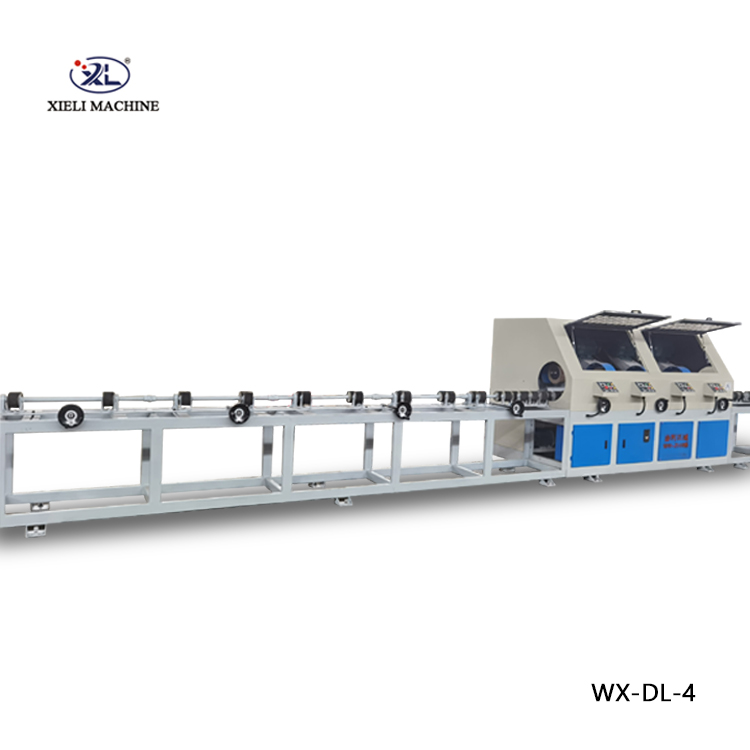

wholesale centerless grinder wheels

One of the primary benefits of high-quality centerless grinder wheels is their ability to maintain precise tolerances across various materials, including metals and plastics. When grinder wheels are manufactured to strict quality standards, they deliver consistent performance, resulting in superior surface finishes and increased productivity. This consistency is crucial, especially for industries that demand high precision, such as aerospace, automotive, and medical device manufacturing.

Moreover, wholesale suppliers often offer a diverse range of grinding wheels suitable for various applications. Different materials, grits, and bond types are available, allowing manufacturers to select the right wheel for their specific needs. For instance, ceramic and diamond wheels are ideal for tough materials, while aluminum oxide wheels work well for softer metals. This diversity enables businesses to tailor their machining processes to achieve optimal results, further enhancing production efficiency.

Another significant advantage of sourcing from wholesale suppliers is the access to technical expertise and support. Many wholesale vendors have extensive knowledge of the grinding process and can provide valuable insights into wheel selection, maintenance, and best practices. This support can help manufacturers troubleshoot problems, optimize their grinding processes, and reduce downtime, ultimately contributing to higher throughput and improved product quality.

In conclusion, wholesale centerless grinder wheels are essential for manufacturers looking to enhance their grinding operations. The ability to procure high-quality wheels at reduced costs, combined with a broad selection and expert guidance, makes wholesale solutions an attractive option for businesses striving for excellence. As the manufacturing sector continues to evolve, investing in top-notch centerless grinding wheels will undoubtedly be a key factor in achieving operational success and maintaining a competitive edge.