Tube Polishing Machine A Key Investment for Quality Finish in the UK

In today’s competitive manufacturing landscape, the quest for excellence drives businesses to invest in high-quality equipment. Among such investments, tube polishing machines play a crucial role, particularly in industries where the finish of metal components is paramount. For companies in the UK looking to enhance their production capabilities, obtaining quotes for tube polishing machines can be a fundamental step toward achieving superior product quality.

Understanding Tube Polishing Machines

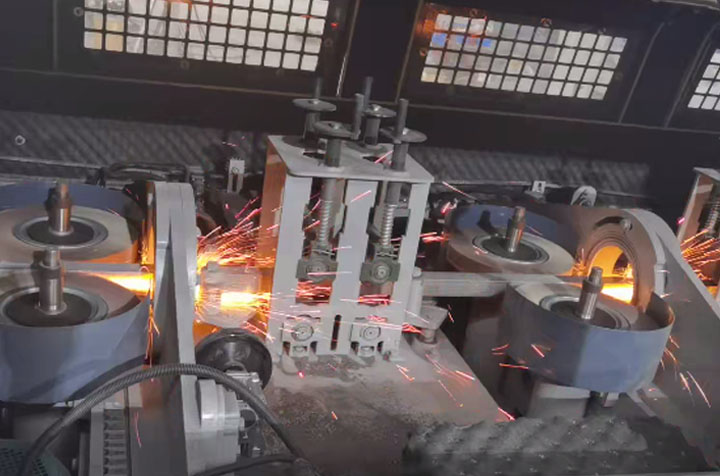

Tube polishing machines are specialized equipment designed to improve the surface finish of tubular products made of metals like stainless steel, aluminum, and brass. These machines eliminate imperfections, scratches, and oxidization, resulting in a sleek, reflective surface that not only enhances aesthetic appeal but also prevents corrosion and extends the lifespan of the products.

Different types of tube polishing machines cater to various needs—some are ideal for large-scale operations, while others are better suited for smaller production runs. They employ several techniques, such as abrasive polishing, mechanical buffing, and chemical finishing, each designed to meet the specific requirements of the manufacturer.

Importance of Surface Finish

A high-quality surface finish is vital for many applications, especially in sectors like food processing, pharmaceuticals, automotive, and architecture. For instance, in the food processing industry, a smooth and clean surface on tubes helps prevent bacterial growth and contamination, ensuring product safety and compliance with health regulations. Similarly, in the automotive sector, a polished finish can reduce friction in exhaust systems, improving efficiency and performance.

Why Obtain Quotes?

When considering the acquisition of a tube polishing machine, obtaining quotes from different suppliers is essential for several reasons

1. Cost Comparison The prices of tube polishing machines can vary significantly based on features, capabilities, and brand reputation. By gathering multiple quotes, businesses can compare prices and select an option that fits their budget while still meeting their specifications.

2. Understanding Features Different machines come with various features that might be beneficial for specific applications. Quoting multiple suppliers allows manufacturers to better understand what is available in the market and how those features can enhance their production processes.

tube polishing machine uk quotes

3. Negotiation Leverage Having several quotes in hand gives businesses leverage when negotiating with suppliers. It enables them to advocate for better terms, prices, or additional services such as installation or training that might come with the purchase.

4. Supplier Reputation Acquiring quotes also opens the door to researching supplier reputations. Customer reviews and after-sales support are critical factors in selecting a manufacturer, and quotes often include references or testimonials that can aid in this evaluation.

The Buying Process

When seeking quotes for tube polishing machines in the UK, businesses should follow a systematic approach

1. Research Suppliers Identify reputable manufacturers and distributors that specialize in tube polishing machines. Online reviews, trade shows, and industry recommendations can be useful in this process.

2. Specify Requirements Outline the specific polishing needs and capacity requirements to ensure that the quotes received are relevant and comparable.

3. Request Detailed Quotes Reach out to multiple suppliers for detailed quotes that include pricing, machine specifications, warranty information, and after-sales service.

4. Evaluate Options After receiving quotes, evaluate them based on price, features, and overall value proposition to make an informed decision.

Conclusion

Investing in a tube polishing machine is a strategic decision for manufacturers in the UK aiming to enhance the quality of their products. By obtaining and comparing quotes, businesses can ensure they choose the right machine that fits their operational needs and budget. In an era where quality standards are continually rising, such equipment is not merely an asset but a necessity for maintaining competitiveness and ensuring customer satisfaction. As the demand for high-quality finishes in metalworking continues to grow, tube polishing machines stand out as essential tools in the manufacturing arsenal.