Tube Polishing Machine Products Manufacturers Elevating Finishing Standards in the Metal Industry

The metal fabrication industry is continuously evolving, and one of its vital aspects is the finishing process of tubes and pipes. Among the various methods of enhancing the aesthetics and durability of metal products, tube polishing stands out as a crucial step. This is where tube polishing machine products manufacturers play a pivotal role, providing innovative solutions that ensure high-quality finishes for metallic tubes.

Understanding Tube Polishing

Tube polishing is the process of refining the exterior surface of metal tubes to achieve a smooth, shiny finish. This not only enhances the appearance of the tubes but also prepares them for further applications, including plating, coating, or welding. The demand for polished tubes spans various industries, including automotive, aerospace, and construction, where aesthetics and corrosion resistance are paramount.

The Role of Tube Polishing Machines

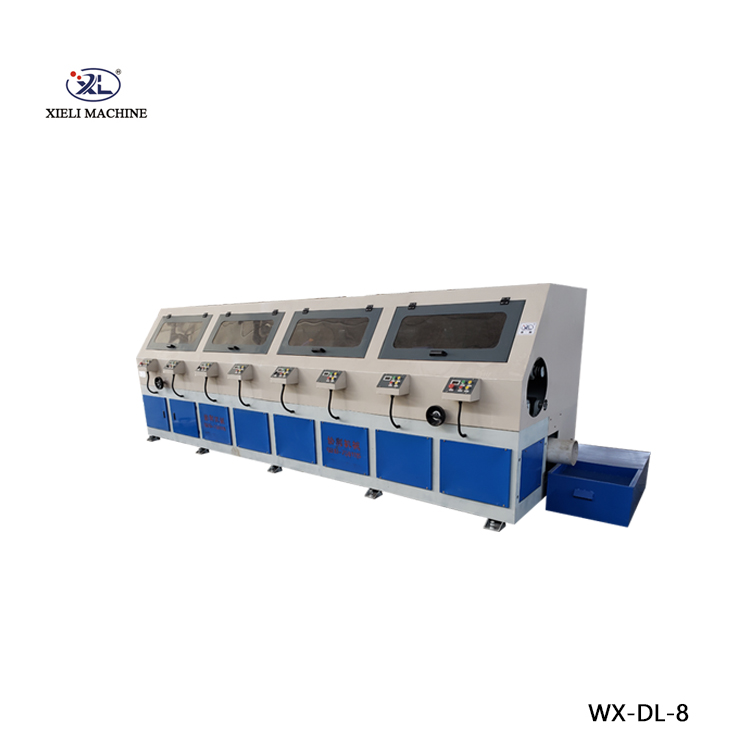

Manufacturers of tube polishing machines supply essential equipment that automates the polishing process. These machines are designed to handle tubes of various sizes and materials, including stainless steel, aluminum, and other alloys. The automation of the polishing process improves efficiency, reduces labor costs, and ensures consistent quality across large production runs.

Modern tube polishing machines incorporate advanced technologies such as CNC (Computer Numerical Control) for precision and control. This automation allows for the precise adjustment of polishing parameters such as speed, pressure, and polishing compounds, which are critical for achieving the desired finish. Furthermore, these machines can accommodate varying tube geometries, including round, square, and rectangular shapes, making them versatile for different manufacturing needs.

Key Features of Tube Polishing Machines

1. Efficiency and Speed Advanced tube polishing machines operate at high speeds, significantly reducing the time required to polish tubes compared to manual processes. This efficiency translates into higher production rates and lower operational costs.

tube polishing machine products manufacturers

2. Flexibility Many manufacturers design machines that can polish tubes of varying lengths and diameters. This flexibility allows businesses to cater to diverse customer needs without the need for multiple machines.

3. Quality Control With integrated monitoring systems, tube polishing machines can ensure a consistent polish quality by adjusting parameters in real time. This capability helps in meeting specific industry standards and reducing the likelihood of defects.

4. User-Friendly Interfaces Most modern polishing machines come equipped with intuitive controls that make them easy to operate. Operators can quickly learn how to use the equipment, minimizing the training time required.

5. Eco-Friendly Solutions Many manufacturers are now focusing on creating machines that use environmentally friendly polishing compounds and processes, aligned with global trends towards sustainability.

The Market Landscape

The market for tube polishing machine products manufacturers is competitive and increasingly global. Companies are constantly striving to innovate, developing machines that feature new technologies or improve upon existing designs. Manufacturers not only compete on the basis of product quality but also on customer service, warranty offerings, and after-sales support, which are increasingly becoming deciding factors for buyers.

Regional manufacturers often focus on specific metalworking industries, enabling them to tailor their products to meet the unique needs of their local markets. Conversely, global manufacturers leverage economies of scale and research and development to create cutting-edge machines that can dominate the market.

Conclusion

Tube polishing machine products manufacturers are essential partners in the metal fabrication industry. As industries around the world continue to grow and evolve, the demand for high-quality polished tubes will only increase. Investing in advanced tube polishing machines not only boosts efficiency and consistency in production but also enhances the final product's aesthetic and functional qualities. In a competitive market, companies that prioritize quality, innovation, and customer-centric solutions will lead the way in shaping the future of tube polishing and the broader metalworking industry.