The Rise of Tube Polishing Machine Manufacturers Revolutionizing Metal Finishing Processes

In the world of manufacturing, the quest for efficiency, quality, and precision has propelled the tube polishing industry into a new era. Tube polishing machines, essential for achieving a fine finish on metal pipes and tubes, have gained significant importance due to their applications in various sectors such as automotive, aerospace, medical, and decorative purposes. The advancements in technology and the increased demand for high-quality polished finishes have led to the emergence of numerous tube polishing machine manufacturers.

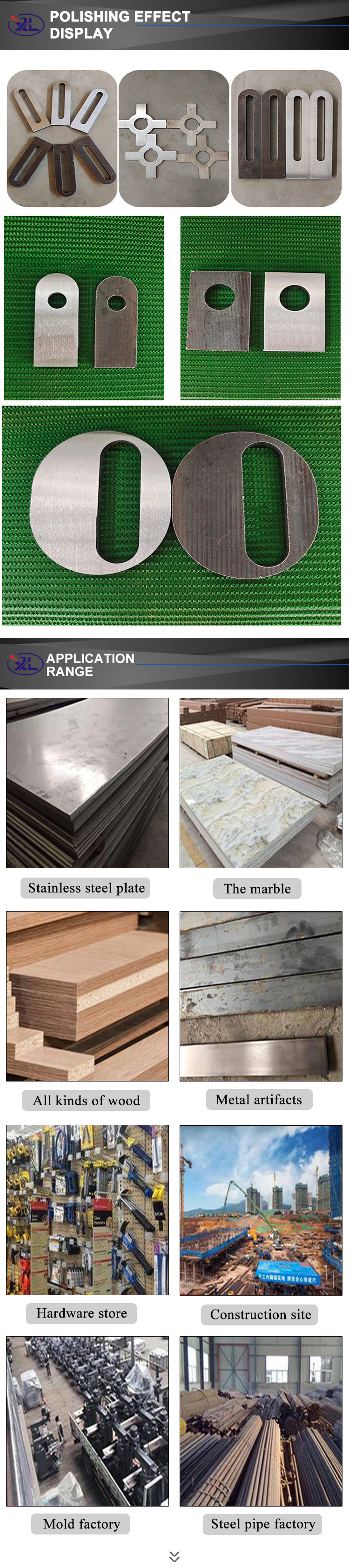

Tube polishing machines are designed to enhance the aesthetic appeal and functional properties of metal surfaces. The process of polishing not only improves visual appearance but also enhances corrosion resistance and cleaning ease. Manufacturers utilize different techniques, including mechanical, chemical, and electrolytic polishing, to achieve the desired results. Each method has its own unique benefits, making it crucial for manufacturers to choose the right technology based on specific needs.

Today’s tube polishing machines come equipped with advanced features such as programmable logic controllers (PLCs), automated feed systems, and real-time monitoring, which significantly enhance productivity and precision. These machines cater to various tube sizes and shapes, allowing for versatile applications. A key consideration for manufacturers when selecting a tube polishing machine is the balance between efficiency and quality. A high-speed machine with a low-quality finish would be counterproductive, leading to increased costs and diminished customer satisfaction.

Furthermore, environmental considerations have driven the evolution of tube polishing machines. Manufacturers are increasingly focusing on developing eco-friendly machines that minimize waste and energy consumption. Technologies such as water-based polishing compounds and closed-loop systems for recycling polishing fluids are becoming industry standards. This shift not only helps in complying with stringent regulations but also resonates well with the environmentally conscious consumers of today.

tube polishing machine manufacturers manufacturer

As the industry evolves, competition among tube polishing machine manufacturers has intensified. Many companies now offer customizable solutions tailored to meet specific customer requirements. For instance, manufacturers may provide machines that vary in size, speed, and functionality. The option for custom solutions allows businesses to optimize their operations and achieve superior finishes, setting them apart in a competitive marketplace.

When selecting a tube polishing machine manufacturer, it is essential to consider several factors. First and foremost, the manufacturer’s experience and reputation in the industry play a critical role. An established manufacturer with a proven track record is more likely to provide a reliable and efficient product. Additionally, after-sales support, including maintenance services and availability of spare parts, should be a significant consideration. A strong relationship with a manufacturer can extend the lifespan of the machine and enhance overall productivity.

In this competitive landscape, innovation remains a driver of success. Leading manufacturers are investing in research and development to bring forth cutting-edge technologies and automation solutions. These innovations aim to reduce manual labor, enhance safety features, and improve the overall user experience. As a result, companies can meet the rising demand for precision-engineered parts, facilitating their expansion into new markets.

Moreover, the digital transformation in manufacturing is influencing tube polishing machines’ design and operation. IoT (Internet of Things) integration allows for real-time data collection and analysis, optimizing machine performance and predictive maintenance. This technological integration not only boosts productivity but also aligns with Industry 4.0 standards, making manufacturers more competitive on a global scale.

In conclusion, the landscape of tube polishing machine manufacturers is evolving rapidly, driven by technological advancements, environmental considerations, and competitive pressures. As industries strive for high-quality finishes and efficient processes, these manufacturers are at the forefront of meeting these demands through innovation and tailored solutions. The future of tube polishing is bright, with opportunities for manufacturers willing to adapt and innovate in this dynamic field. The ongoing evolution in machining technology is not just shaping the products but also redefining the capabilities of manufacturers across the globe.