Understanding Tube Polishing Machine Manufacturers Quotes and Insights

When it comes to the manufacturing of industrial components, tube polishing machines play a vital role in ensuring that metallic tubes not only meet functional specifications but also possess the aesthetic appeal required for various applications. Whether used in industries such as automotive, aerospace, or furniture manufacturing, these machines are designed to enhance the surface finish of tubes, making them smoother and more visually appealing. In this article, we will explore various aspects related to tube polishing machine manufacturers and the significance of quotes in the purchasing process.

The Importance of Tube Polishing Machines

Tube polishing machines utilize different techniques, such as mechanical polishing, buffing, and electropolishing, to achieve the desired surface finish on metal tubes. The process is essential for removing scratches, oxidation, and other imperfections while achieving a high-gloss appearance. As industries become increasingly competitive, manufacturers seek tube polishing machines that can deliver precision, reliability, and efficiency.

Moreover, with the growing demand for customized products, these machines often come with advanced features for versatility in operations. Manufacturers focused on this sector must meet the evolving needs of clients, often presenting cost-effective and innovative solutions.

Key Considerations When Choosing a Manufacturer

1. Quality and Reliability It’s crucial to partner with manufacturers known for their high-quality products. A reputable manufacturer will provide robust machines that minimize downtime and enhance productivity.

2. Technological Advancements As technology evolves, so do the features of tube polishing machines. Look for manufacturers who offer the latest innovations, including automation and smart technology, which can lead to better performance and easier operation.

3. After-Sales Support A reliable manufacturer should provide comprehensive after-sales support, including maintenance services, spare parts availability, and technical assistance. This support ensures that operations continue smoothly without unnecessary interruptions.

4. Customization Options Every industry has unique requirements. A good manufacturer will offer customization options to tailor machines according to specific needs, whether that means changes in size, polishing methods used, or special features incorporated.

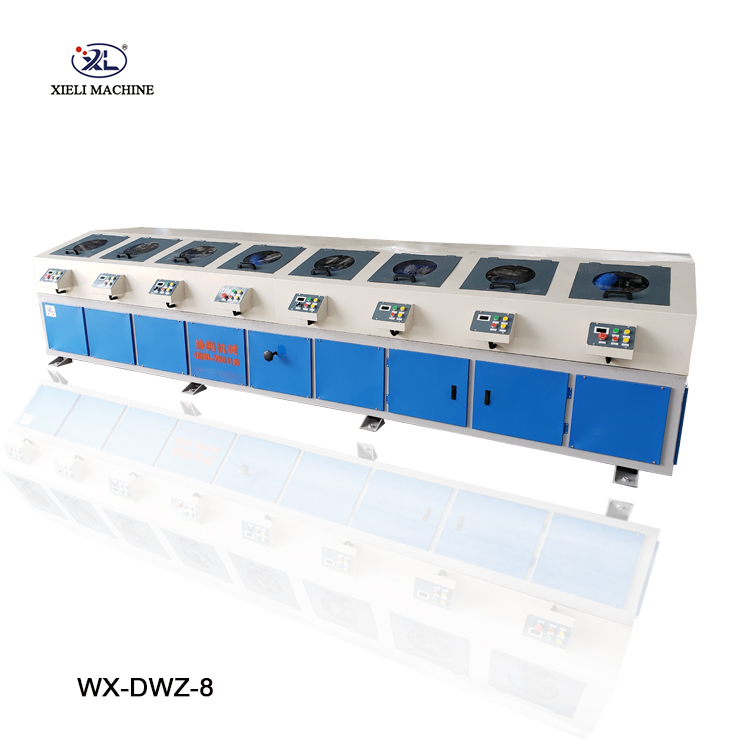

tube polishing machine manufacturer quotes

5. Financial Aspects Considering the cost of machines is vital. Manufacturers should provide clear and transparent pricing structures to prevent hidden costs later.

Gathering Quotes from Manufacturers

When deciding to purchase a tube polishing machine, obtaining quotes from multiple manufacturers is a wise strategy. Here’s how to effectively gather and evaluate these quotes

- Define Your Requirements Clearly outline what you require from the tube polishing machine. Consider aspects such as the type of materials to be polished, the volume of production, and the desired finish quality.

- Request Detailed Quotes When reaching out to manufacturers, ensure they provide detailed quotes that include not only the base price but also information on any additional features, warranties, and shipping costs.

- Comparative Analysis Once you receive the quotes, conduct a comparative analysis. Look for the best value rather than just the lowest price. Assess the quality, support, and additional features provided in each quote.

- Seek Recommendations Often, word of mouth can lead you to trusted manufacturers. Speak with industry peers to gather insights on their experiences with specific manufacturers and any recommendations they may have.

Conclusion

In the highly competitive landscape of industrial manufacturing, selecting the right tube polishing machine is crucial for ensuring product quality and operational efficiency. By understanding the key factors to consider when choosing a manufacturer and gathering detailed quotes, businesses can make informed decisions that align with their specific needs.

Investing time and effort in this process pays off in the long run—enabling manufacturers to enhance their production capabilities and maintain a competitive edge in the market. In essence, the right partnership with a tube polishing machine manufacturer can lead to mutually beneficial outcomes, fostering growth and innovation within the industry.