Tube Polishing Machine for Sale A Comprehensive Guide

In the modern manufacturing landscape, the need for quality finishing processes is paramount. Among these processes, tube polishing has emerged as a crucial step to enhance the aesthetic appeal and functional performance of metal tubes and pipes. For businesses looking to invest in tube polishing machinery, understanding the options available in the market can ensure better decisions and improved outcomes.

What is a Tube Polishing Machine?

A tube polishing machine is a specialized tool designed to smooth and polish the surface of metal tubes. By utilizing various polishing techniques—such as mechanical, electrochemical, or chemical polishing—these machines can effectively remove imperfections, burrs, and oxidation, resulting in a shiny, smooth surface. This not only enhances the appearance but also increases corrosion resistance, which is vital for many applications in industries like automotive, aerospace, and construction.

Types of Tube Polishing Machines

There are several types of tube polishing machines available, each tailored to specific requirements

1. Belt Polishing Machines These machines use abrasive belts to polish the tubes. They are versatile and can handle various tube sizes and materials, making them suitable for small workshops to large manufacturing plants.

2. Rotary Polishing Machines Equipped with a rotating head, these machines provide a fine polish to the surface of the tubes. They are often used for finishing stainless steel and aluminum tubes.

3. Centerless Polishing Machines These machines do not rely on a conventional setup of a holding device. Instead, they use the concept of centerless grinding to polish the tubes uniformly. This method is efficient for high-volume production as it allows continuous feeding of tubes.

4. Manual Polishing Machines For smaller operations, manual machines are often employed. These are typically handheld tools that require an operator to move the tool across the tube surface, often used for intricate details or small-scale projects.

5. Automated Polishing Systems These are advanced machines that use robotic technology to automate the polishing process. Suitable for high-volume production lines, they ensure consistent quality while minimizing labor costs.

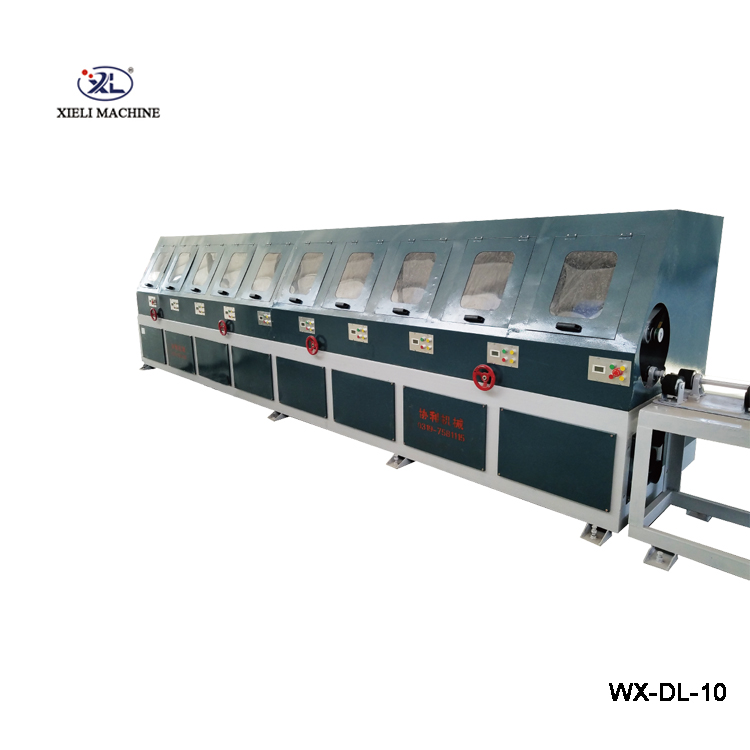

tube polishing machine for sale supplier

Factors to Consider When Purchasing

When looking to purchase a tube polishing machine, there are several critical factors to consider

1. Material Compatibility Ensure the machine can handle the specific materials you will be polishing, such as stainless steel, aluminum, or copper.

2. Tube Size Range Evaluate the range of tube diameters and lengths that the machine can accommodate. This is essential for ensuring versatility in your operations.

3. Production Capacity Consider how quickly you need the polishing to be completed. Automated machines offer higher throughput than manual options.

4. Ease of Use Look for machines that are user-friendly and require minimal training for operators. Features such as digital displays and programming interfaces can facilitate ease of operation.

5. Maintenance Requirements Check the maintenance protocols for the machine. Machines that require frequent servicing can add unexpected costs and downtime.

6. Supplier Reputation Research the supplier's credibility by checking reviews, testimonials, and their after-sales support. A reliable supplier will offer not only quality machines but also necessary training and service support.

7. Cost Evaluate the total cost of ownership, which includes the purchase price, operational costs, and maintenance. Sometimes, a more expensive machine is a better investment if it offers efficiency and durability.

Conclusion

Investing in a tube polishing machine can substantially enhance your production quality and efficiency. With a range of options available, from manual machines to fully automated systems, businesses can find the right equipment to meet their specific needs. By considering factors such as material compatibility, production capacity, and supplier reputation, companies can make informed decisions that will provide long-term benefits. As the demand for high-quality metal surfaces continues to grow, acquiring a reliable tube polishing machine will position your business advantageously in a competitive marketplace.