Tube Mirror Polishing Machine A Comprehensive Overview

In the manufacturing and metalworking industries, achieving a polished finish on tubular components is essential for both aesthetic appeal and functionality. The tube mirror polishing machine has emerged as an invaluable tool for this purpose, ensuring that metal tubes not only meet stringent quality standards but also enhance their durability and resistance to corrosion. As industries evolve, so too does the technology behind these machines, culminating in a variety of options that cater to different production needs.

Understanding Tube Mirror Polishing Machines

At its core, a tube mirror polishing machine is designed to produce a high-gloss finish on cylindrical metal surfaces. This process is crucial in industries such as automotive, aerospace, and decorative applications, where the visual appeal of a product can significantly impact its marketability. These machines use a combination of abrasive belts, brushes, and polishing compounds to seek out a flawless finish. The versatility of these machines allows them to handle various materials, including stainless steel, aluminum, and brass, making them a go-to choice for manufacturers.

Key Features and Benefits

1. Efficiency and Speed Modern tube mirror polishing machines are engineered for high efficiency, reducing the time it takes to polish individual pieces. With advanced automation, these machines can polish multiple tubes simultaneously, thereby increasing overall productivity.

2. Quality Finish The end product of tube polishing is often a mirror-like finish that not only enhances appearance but also improves resistance to wear and tear. This quality is particularly important in applications where hygiene and aesthetic standards are paramount, such as in food processing and decorative architecture.

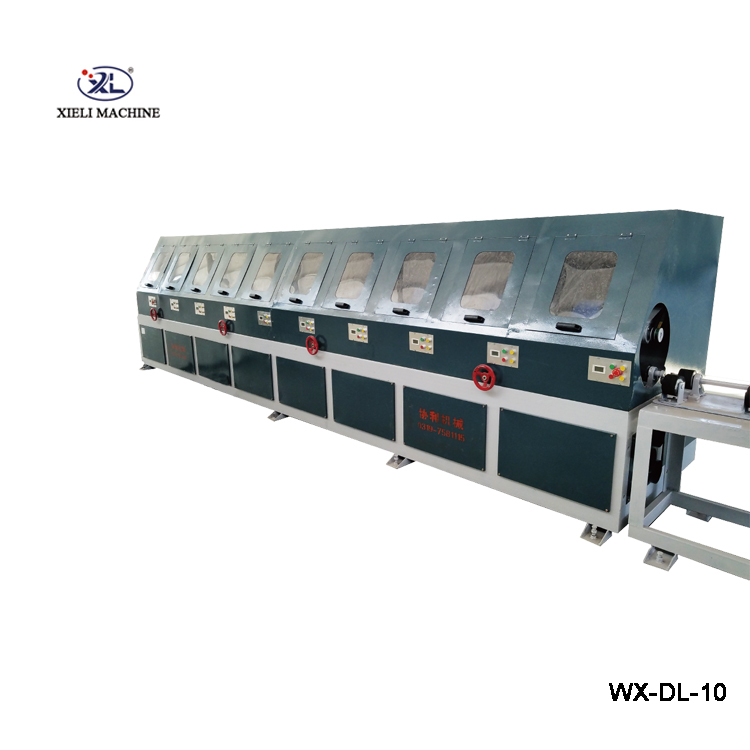

tube mirror polishing machine quotes

3. Customizability Manufacturers can often customize tube polishing machines according to their needs. Options include adjustable speeds, various abrasive materials, and the ability to polish different tube diameters, ensuring that businesses can meet specific production requirements.

4. Cost-Effectiveness While the initial investment in a tube mirror polishing machine may seem substantial, the long-term savings due to reduced labor costs and wastage make it a worthwhile addition to any production line. Furthermore, the improved finishing quality can lead to higher customer satisfaction and fewer returns.

Pricing Insights

When it comes to acquiring a tube mirror polishing machine, potential buyers should consider several factors that influence pricing. Equipment brand, machine features, and production capacity often dictate the cost. Basic models may start at a lower price point, while high-end machines with advanced automation capabilities can range into the tens of thousands of dollars. It is essential for businesses to balance their budget with their production needs—sometimes investing in a more expensive machine can lead to long-term savings.

Conclusion

The tube mirror polishing machine stands at the intersection of technology and craftsmanship, providing manufacturers with the tools necessary to deliver quality polished finishes effectively. As demand for high-quality products continues to rise, these machines will play a pivotal role in ensuring companies remain competitive. Whether for enhancing product aesthetics or improving durability, investing in a tube mirror polishing machine can lead to significant advancements in operational efficiency and product quality. For businesses looking to optimize their metal finishing processes, exploring the array of available options in tube mirror polishing machines may be the key to success.