Tube Mirror Polishing Machine Companies An Overview of the Industry

In recent years, the demand for high-quality polished tubes has surged, driven by various industries, including automotive, aerospace, and manufacturing. This demand has led to the rise of tube mirror polishing machine companies that specialize in producing advanced machinery capable of delivering impeccable polishing results. These companies play a crucial role in enhancing the surface finish of tubes, thereby improving their aesthetic appeal and functional performance.

The Importance of Tube Polishing

Polishing tubes is essential for several reasons. First and foremost, a polished surface improves the material's resistance to corrosion and other forms of wear. By creating a smooth finish, these tubes are better suited to withstand harsh environments, particularly in industries such as petrochemical and food processing, where hygiene is paramount. Moreover, polished tubes are often required for aesthetic reasons in sectors such as architecture and automotive design, where visual appeal can significantly influence a product’s marketability.

Key Features of Tube Mirror Polishing Machines

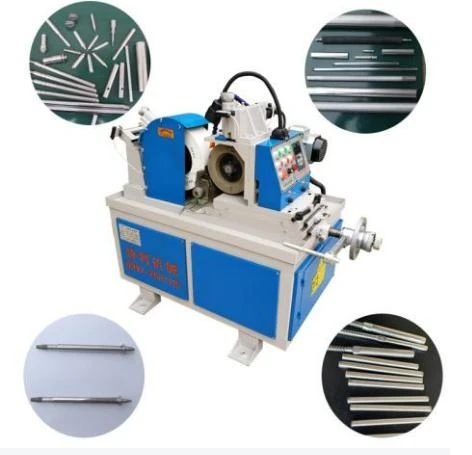

Tube mirror polishing machines are designed with specific features that allow them to achieve the highest quality finishes. These machines typically utilize specialized abrasives and polishing compounds, along with advanced automation and control systems that ensure consistency and precision in the polishing process.

1. Versatility Many modern polishing machines are equipped to handle various tube sizes and materials, making them suitable for different applications. Whether dealing with stainless steel, aluminum, or other metals, these machines can be adjusted to deliver optimal results.

2. Efficiency The latest tube polishing machines leverage automation technologies that increase productivity. Features such as programmable settings, conveyor systems, and quick-change tooling allow for faster setup times and less downtime, significantly boosting the operational efficiency of factories.

3. Quality Control Leading companies in this sector often incorporate stringent quality control measures in their manufacturing processes. Machines are designed to produce results that meet or exceed industry standards. Many manufacturers offer additional technology for inspection and testing, ensuring that each polished tube meets the required specifications.

tube mirror polishing machine companies

Notable Players in the Market

The tube mirror polishing machine market is home to several key players known for their innovative solutions and high-quality products. Companies such as Timesavers, Inc., and Rosenberg Group have earned reputations for their high-performance machines, catering to both small manufacturers and large industrial operations. These companies often provide a full range of services, including the design and manufacture of custom polishing machines, which are tailored to the specific needs of their clients.

Another notable company is Baileigh Industrial, which offers a variety of metalworking equipment, including tube polishing machines that excel in user-friendliness and reliability. Their machines are designed for both small workshops and large-scale production environments, emphasizing the versatility that many users seek.

Future Trends

Looking forward, the tube mirror polishing machine industry is likely to see continued advancements driven by technological innovation. Increasingly, manufacturers are adopting Industry 4.0 principles, incorporating IoT (Internet of Things) technologies into their machines. This integration allows for real-time monitoring and adjustments, enhancing efficiency, and minimizing defects in the polishing process.

Furthermore, sustainability is becoming a significant focus within the industry. Companies are working towards developing more eco-friendly polishing solutions, including the use of biodegradable polishing compounds and energy-efficient machines that reduce the overall carbon footprint of the manufacturing process.

Conclusion

The tube mirror polishing machine industry is a vital sector that underpins many manufacturing processes. As demand for high-quality, polished tubes continues to grow, so too does the innovation within this niche market. Companies specializing in tube polishing machinery are not only providing essential equipment but are also driving the standards of quality, efficiency, and sustainability in the manufacturing world. With the advent of new technologies, the future of tube mirror polishing machines looks promising, ensuring that this industry remains strong and relevant in the global market.