The Importance of Tube Internal Polishing Machines A Look at Pricing and Features

In the world of metalworking and manufacturing, the quality of the final product is often as crucial as the efficiency of the production process. One key aspect of ensuring high-quality metal products is the finishing process, particularly when it comes to tubes. Tube internal polishing machines play a vital role in enhancing the surface finish of tubes, which is essential in various industries, including automotive, aerospace, and food processing. Understanding the pricing of these machines can help businesses make informed purchasing decisions.

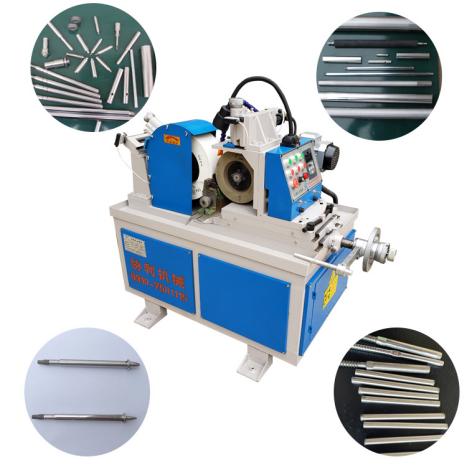

What is a Tube Internal Polishing Machine?

A tube internal polishing machine is designed to improve the internal surface finish of metal tubes. These machines remove scale, rust, and other contaminants from the interior surface, resulting in a smooth and polished finish that is essential for many applications. The polishing process can enhance the aesthetic appeal of the tubes and reduce friction, improving the performance of the respective applications. This is particularly important in industries where high cleanliness and low friction are critical, such as in hydraulic systems or food processing equipment.

Features to Consider

When looking at tube internal polishing machines, several features should be considered to understand their value and pricing

1. Automation Level Machines vary in their level of automation, from manual to fully automated systems. Automated machines may have a higher upfront cost but can lead to significant savings in labor and time.

2. Size and Capacity The size of the tubes being polished and the machine's capacity to handle different dimensions will affect the pricing. Machines capable of polishing a wider range of sizes may be more expensive.

3. Polishing Mechanism Different machines utilize various polishing techniques, such as mechanical polishing, electrolytic polishing, or abrasive blasting. The technology and methodology used can significantly impact the price.

tube internal polishing machine pricelist

4. Material Compatibility It's essential to consider whether the machine can handle different materials, including stainless steel, aluminum, or exotic alloys. Multi-material capability often comes at a premium.

5. Customization Options Some manufacturers offer customizable machines tailored to specific production needs. Custom features can lead to higher costs but may improve efficiency and output quality in the long run.

Price Range

The pricing of tube internal polishing machines can vary widely based on the features and specifications mentioned above. On the lower end, basic models may start around $10,000 to $20,000. These machines typically provide essential polishing functions and are suitable for small-scale operations or lower production volumes.

Mid-range machines, which offer better automation and advanced features, can range from $20,000 to $50,000. These models are ideal for manufacturers looking for a balance between cost and performance.

At the high end, fully automated and highly specialized polishing machines can cost upwards of $100,000 or more. These machines cater to high-volume production facilities and industries where precision and efficiency are paramount.

Conclusion

Investing in a tube internal polishing machine is a significant decision for any manufacturing business. While the initial cost may be a concern, the long-term benefits of improved product quality, increased efficiency, and reduced operational costs can far outweigh the expense. As businesses look to enhance their production capabilities, understanding the pricing and features of these machines will be crucial to making an informed choice. By carefully considering the specific needs of your operation, you can choose a machine that not only fits your budget but also elevates the quality of your products.