Understanding Tube Buffing Machine Price Lists A Comprehensive Guide

In the world of manufacturing and metal finishing, tube buffing machines play a crucial role in ensuring that metal tubes have a polished and professional finish. These machines are designed to remove oxidation, scratches, and defects from the surface of tubes, making them look aesthetically pleasing and ready for further applications. As the demand for high-quality finishes continues to grow across various industries, understanding the pricing of tube buffing machines becomes essential for businesses and manufacturers. This article will explore what influences the pricing of these machines and help you navigate through a typical price list.

Factors Affecting Tube Buffing Machine Prices

1. Type of Machine The type of tube buffing machine significantly impacts its price. Machines can vary from manual models, which are often less expensive, to fully automated systems equipped with advanced technological features. Automated machines tend to be more expensive due to their enhanced efficiency, precision, and the capabilities they offer for high-volume production.

2. Size and Capacity The size of the machine also plays a vital role in determining its cost. Larger machines that can handle bigger tubes or higher capacities often come with a higher price tag. Buyers need to consider their production requirements and choose a machine that fits their specific needs without leading to unnecessary expenditures.

3. Material Quality The materials used in the construction of tube buffing machines can influence their price. Machines made from high-quality, durable materials may cost more initially but are often more efficient and long-lasting. Investing in a machine made from robust materials can lead to better performance and lower maintenance costs in the long run.

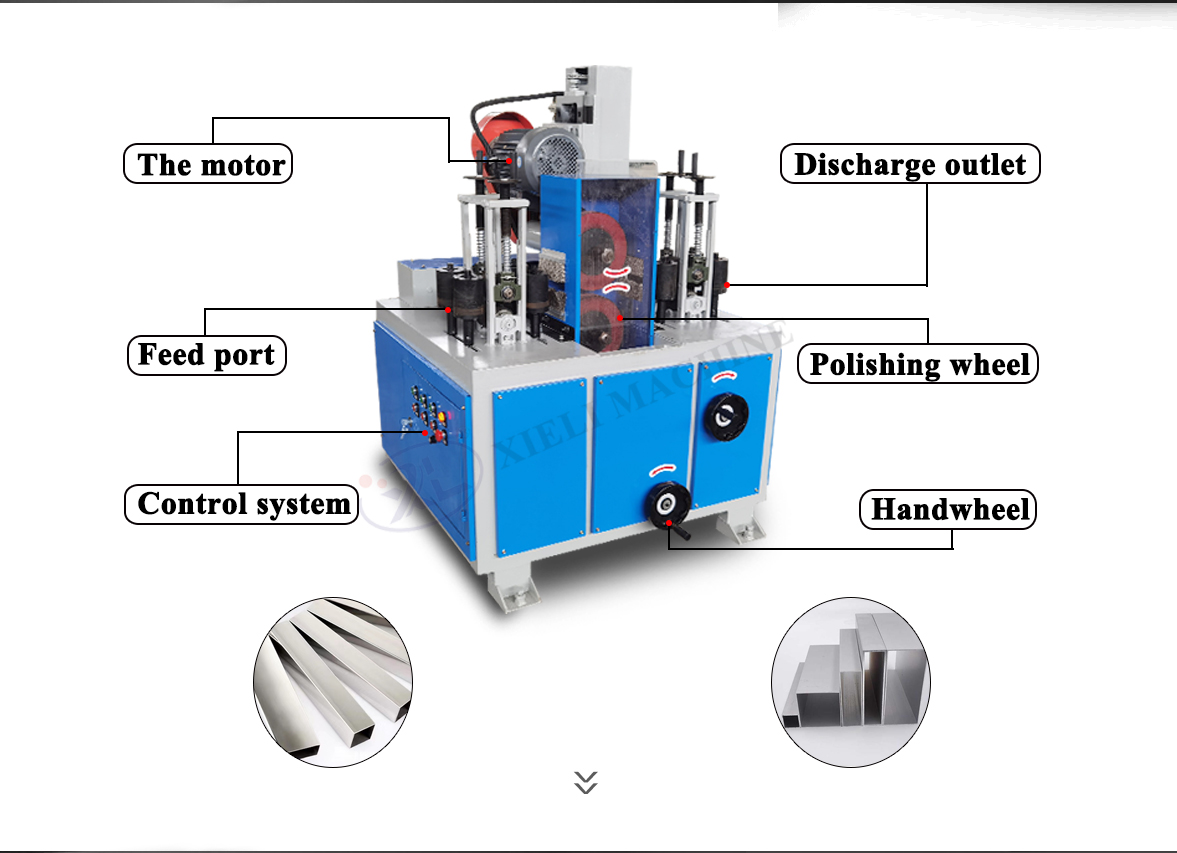

4. Additional Features Many manufacturers offer tube buffing machines with additional features such as digital controls, adjustable speed settings, and specialized buffing wheels. These advanced features typically increase the cost of the machine, but they also enhance usability and efficiency. Prospective buyers should weigh the benefits of these features against their budget and operational needs.

5. Brand Reputation The reputation of the manufacturer significantly affects the pricing. Established brands with a track record of reliability and quality may charge a premium for their machines. However, investing in a reputable brand can often yield better after-sales support and warranty options, making it a worthwhile investment.

6. Market Trends Like any industry, the market for tube buffing machines can experience fluctuations. Prices can vary based on demand, technological advancements, and raw material costs. Keeping an eye on industry trends and market conditions can help buyers make informed purchasing decisions.

tube buffing machine pricelist

Navigating a Tube Buffing Machine Price List

When exploring a price list for tube buffing machines, it is crucial to look beyond the numbers. Here are a few tips for effectively understanding and comparing prices

- Specifications Always check the specifications of each machine listed. Look for details regarding motor power, tube size compatibility, and buffing speeds. Knowing what each machine can do helps you determine value for money.

- Comparative Analysis Don’t limit yourself to a single manufacturer. Examine multiple price lists from different companies. This not only provides insight into price differences but also helps in identifying the best features relative to cost.

- Customer Reviews Researching customer reviews and testimonials can provide additional context to the prices listed. Feedback from other users can shed light on the performance and reliability of a machine.

- Long-term Value Consider the total cost of ownership. A cheaper machine might save money upfront but could have higher maintenance costs or a shorter lifespan. Assess the expected return on investment (ROI) before making a decision.

Conclusion

Investing in a tube buffing machine is a significant decision that can affect your production capabilities and product quality. Understanding the factors that influence pricing and how to navigate a price list is essential for making an informed choice. By considering machine type, size, materials, additional features, brand reputation, and market trends, businesses can find the right tube buffing machine that meets their needs and budget, ultimately leading to enhanced operational efficiency and product quality in the long run.