Tube Belt Polishing Machine Manufacturers Enhancing Efficiency and Quality in Metal Finishing

In the metal fabrication industry, the appearance and surface quality of the final product can significantly influence customer satisfaction and market competitiveness. For manufacturers dealing with stainless steel, aluminum, and other alloys, achieving a high-quality finish is paramount. One of the essential tools in this quest for perfection is the tube belt polishing machine, which has become a vital asset in modern manufacturing processes.

Understanding Tube Belt Polishing Machines

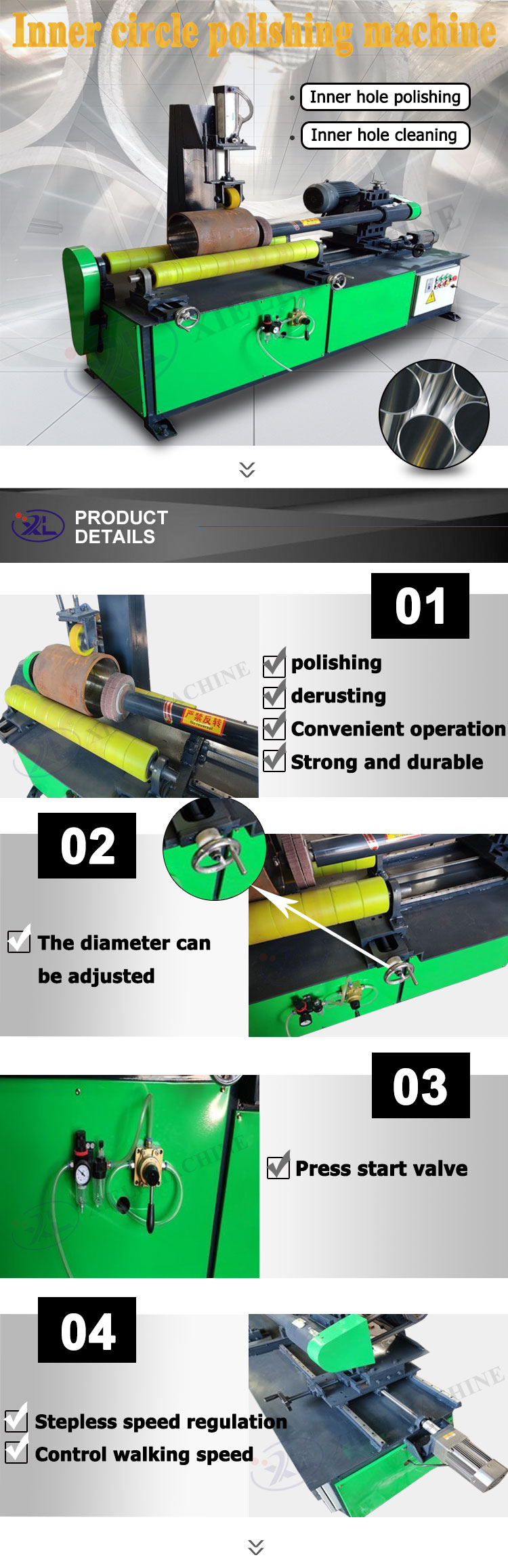

A tube belt polishing machine is a specialized piece of equipment designed to polish, grind, and finish tubular metal products. The mechanism typically involves a continuous belt that moves over the surface of the tube, providing a uniform finish while removing any imperfections or residues. This process not only enhances the visual appearance of the metal but also prepares the surface for further processes such as coating or painting.

These machines can be utilized for various applications, including automotive, aerospace, and architectural components. The versatility of tube belt polishing machines makes them an indispensable tool for manufacturers looking to streamline their operations and improve product quality.

The Importance of Quality Manufacturers

Choosing a reliable tube belt polishing machine manufacturer is crucial for ensuring operational efficiency and product quality. High-quality manufacturers often incorporate advanced technology and rigorous quality control measures into their production processes. They ensure that their machines can handle a wide range of tube sizes, materials, and polishing requirements. This adaptability is essential for companies that operate in diverse industries.

Reputable manufacturers also prioritize customer support and service. A solid warranty, timely maintenance, and a responsive customer service team are critical elements that can significantly impact a manufacturer’s success. By working closely with manufacturers who offer these benefits, businesses can ensure minimal downtime and consistent production quality.

Key Features to Look For

tube belt polishing machine manufacturers

When selecting a tube belt polishing machine, it is essential to consider several key features that can impact performance

1. Adjustability The machine should have adjustable speed and pressure settings to cater to different materials and desired finishes. This feature allows operators to refine their polishing techniques based on specific project requirements.

2. Belt Quality The durability and quality of the polishing belt are paramount. A high-quality belt can significantly influence the polishing outcomes and the longevity of the machine.

3. Safety Features Given the industrial nature of these machines, safety features such as emergency stop buttons, protective guards, and dust extraction systems are crucial to ensure the safety of operators and work environments.

4. Ease of Use User-friendly controls and setup processes reduce the learning curve for operators, enabling quicker adoption and efficient production.

5. Maintenance Requirements Machines that are easy to maintain and service not only save time but also help in prolonging the lifespan of the equipment.

Conclusion

The global market for tube belt polishing machines continues to grow, driven by the increasing demand for high-quality finishes in various industries. As manufacturers strive to enhance their production processes, partnering with reputable tube belt polishing machine manufacturers is an essential step towards achieving operational excellence.

In conclusion, the investment in high-quality tube belt polishing machines not only improves the aesthetic and functional qualities of metal products but also contributes to overall production efficiency. With technological advancements and the introduction of innovative features, the future of tube belt polishing machines looks promising. Manufacturers should remain informed about the latest developments in the industry to leverage these advancements for improved performance and quality in their metal finishing processes.