Steel Pipe Polishing Machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Xingtai Xieli Machinery Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Steel Pipe Polishing Machine Overview

- Benefits & Use Cases of Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

Steel Pipe Polishing Machine Overview

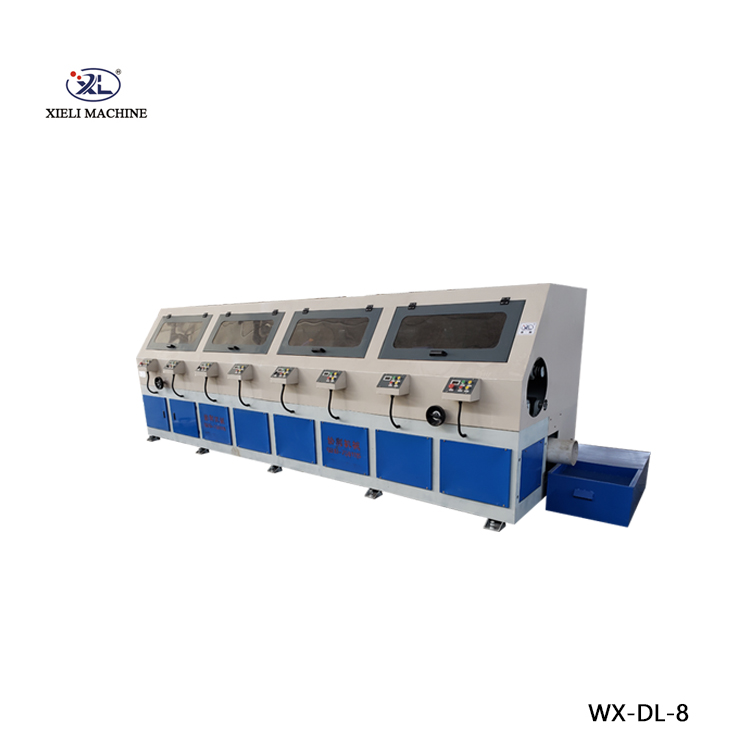

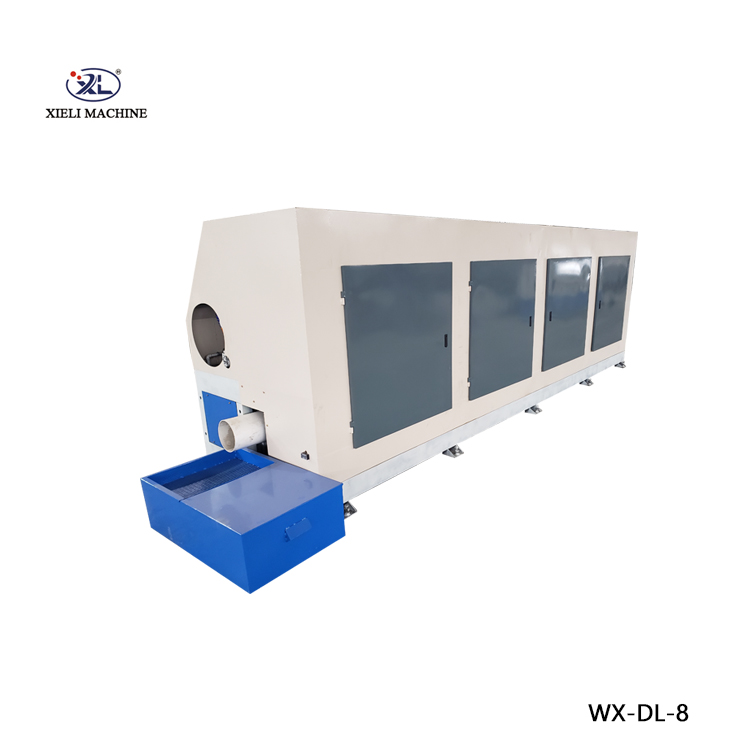

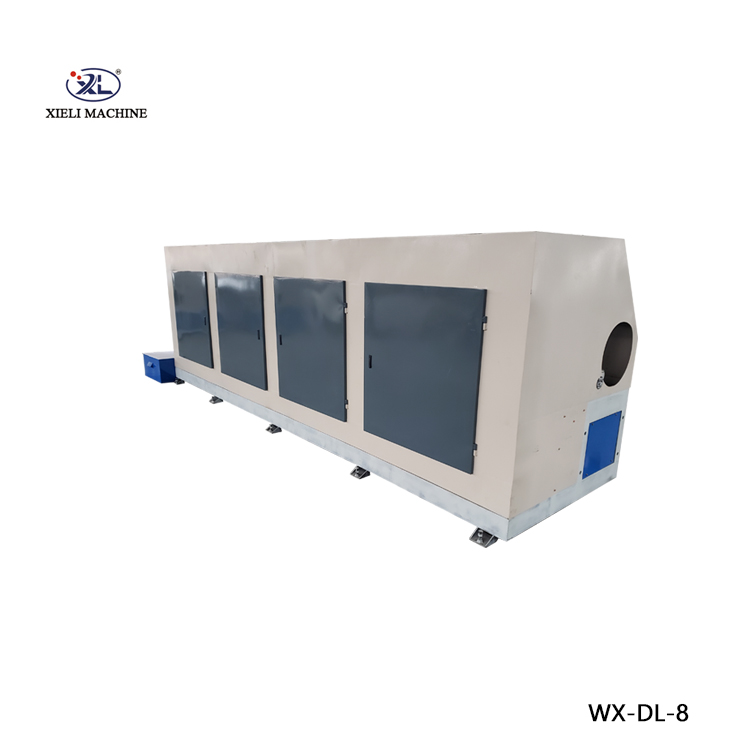

In the Special Equipment Manufacturing Industry, surface integrity is non-negotiable. A Steel Pipe Polishing Machine is engineered to remove rust, mill scale, and surface imperfections from carbon steel and stainless tubes, delivering consistent finishes for downstream processes like bending, welding, plating, powder coating, and sanitary applications. Xingtai Xieli Machinery Manufacturing Co., Ltd. designs wet-type systems that suppress dust, reduce heat, and stabilize finish quality—critical for safety and compliance in modern factories. Often referred to as a steel pipe polish machine, this equipment integrates automated feeding, abrasive belts or flap wheels, and coolant circulation to ensure repeatability at production speed.

- Relevance: Delivers uniform RA and visual finishes (e.g., 120–600 grit satin or hairline) that drive fit, corrosion resistance, and aesthetics in metal processing machinery manufacturing.

- Technical background: Configurable multi-station heads, PLC control, variable-speed feeding, wet rust removal, and closed-loop coolant filtration; compatible with a wide OD range and continuous lengths depending on line layout.

- Trusted maker: Xingtai Xieli Machinery Manufacturing Co., Ltd. brings proven engineering, stable supply of spares/consumables, and tailored solutions for global B2B customers.

Benefits & Use Cases of Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

From tube mills to fabrication cells, polishing is a throughput lever. Typical applications include furniture tubing, handrails, heat exchanger tubes, hydraulic lines, architectural profiles, and oil & gas casing accessories. By integrating a Steel Pipe Polishing Machine inline or near welding cells, manufacturers achieve cleaner joints, lower rework, and improved coating adhesion. Xingtai Xieli’s wet systems enable fast rust removal and pre-finish preparation while minimizing airborne dust, ideal for continuous production and EHS compliance. Features like quick-change belts, adjustable pressure, and precise OD centering ensure repeatable quality across product families.

- Applications: Pre-weld prep, post-weld blending, decorative finishing, and anti-corrosion prep for painting or galvanizing lines.

- Advantages: Consistent finish, reduced scrap, faster takt times, wet dust suppression, and lower operator fatigue via automation and ergonomic controls.

- Expertise: Xingtai Xieli Machinery Manufacturing Co., Ltd. configures machines for varying ODs, materials, and finish grades, supporting turnkey layouts, training, and acceptance testing.

Cost, Maintenance & User Experience

Total cost of ownership for a Steel Pipe Polishing Machine is driven by energy use, abrasive consumption, coolant handling, and uptime. Wet polishing typically extends abrasive life and protects parts and operators, supporting quicker ROI when utilization is steady. Many buyers report ROI within one to two budget cycles, supported by lower rework, less manual labor, and higher first-pass yield. Xingtai Xieli’s robust frames, industrial-grade bearings, and VFD-controlled motors deliver durability and stable performance for multi-shift operations.

- Maintenance: Daily cleaning, belt/wheel inspection, coolant filtration checks, and periodic bearing lubrication. Designed for quick-change consumables to reduce downtime.

- User feedback: Customers in the Special Equipment Manufacturing Industry highlight consistent finishes across mixed OD batches, straightforward operator training, and responsive after-sales support and spare parts availability from Xingtai Xieli Machinery Manufacturing Co., Ltd.

Sustainability & Market Trends in manufacturing

Manufacturers face rising expectations on environmental performance, worker safety, and traceability. Wet polishing aligns with dust control goals and helps meet EHS standards by limiting airborne particulates compared with dry grinding. At the same time, infrastructure, construction, and energy investments are driving demand for corrosion-resistant and visually consistent steel tubes, making polishing capacity a strategic asset. Smart features—like energy-efficient motors, coolant recirculation, and filtration—support reductions in resource use and operating costs.

- Regulatory and ESG focus: Cleaner air, safer workplaces, and lower waste streams favor wet-type systems with closed-loop filtration and easy waste handling.

- Forward-thinking supplier: Xingtai Xieli Machinery Manufacturing Co., Ltd. offers configurable coolant management, efficient drives, and automation options to help B2B decision makers meet sustainability commitments without compromising throughput.

Conclusion on Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

For manufacturers in the Special Equipment Manufacturing Industry and the broader Manufacturing of metal processing machinery sector, a Steel Pipe Polishing Machine is a proven way to elevate finish quality, accelerate takt time, and cut rework. Xingtai Xieli Machinery Manufacturing Co., Ltd. combines dependable engineering with application-specific configurations and responsive service, making it a trusted partner for production lines worldwide. Ready to upgrade your polishing capability and throughput?

- Contact us: email: xtjgjc@163.com

- Visit our website: https://www.xielizz.com

Learn more or request a quote: Product page