Stainless Steel Square Pipe Polishing Machine Suppliers A Comprehensive Overview

In the manufacturing industry, the aesthetic appeal and surface finish of stainless steel products are crucial. Among the various products in this category, stainless steel square pipes are widely used in construction, automotive, and various industrial applications. To achieve the desired surface quality, the polishing process becomes essential, paving the way for the need for dedicated polishing machines. This article will explore the suppliers of stainless steel square pipe polishing machines, emphasizing their importance in the industry.

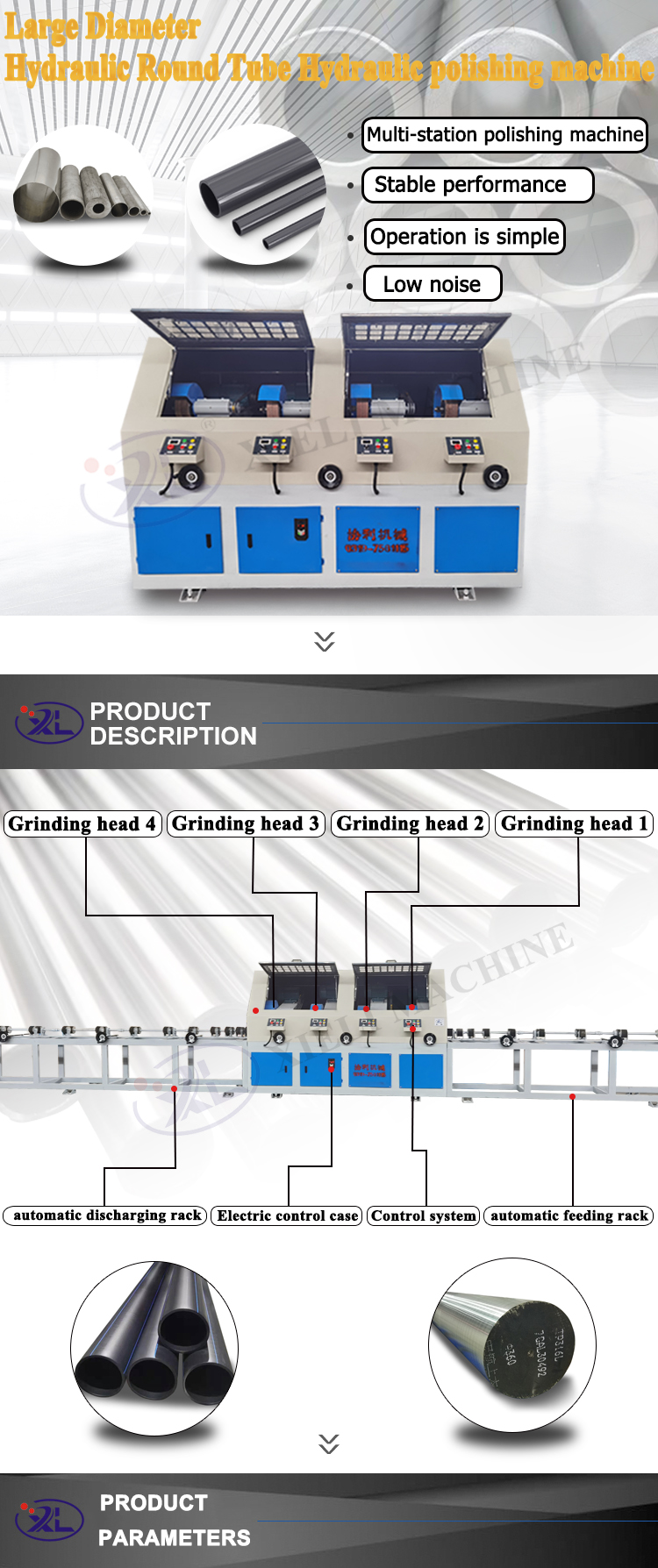

Polishing machines for stainless steel square pipes are designed to enhance the surface finish, providing a smooth and shiny appearance that is both visually appealing and functional. These machines employ advanced technology and various abrasive methods to remove imperfections and achieve the required surface standards. Suppliers of these machines play a pivotal role in helping manufacturers produce high-quality finished products that meet the increasing demands of the market.

When selecting a polishing machine supplier, several factors come into play. Firstly, the quality of the machines is paramount. Reputable suppliers often offer machines constructed with high-quality materials, ensuring durability and long service life. They typically provide machines that are tailored to handle different sizes and shapes of square pipes, accommodating the diverse needs of their clients.

stainless steel square pipe polishing machine suppliers

Another critical aspect to consider is the supplier's technical support and after-sales service. Well-established suppliers generally have a dedicated support team to assist clients with installation, operation, and maintenance issues. This support is invaluable, especially for companies that are new to the polishing process or new to operating such machines.

Cost is also a significant consideration for manufacturers when sourcing polishing machines. While it is tempting to go for the lowest price, it is essential to assess the value offered by each supplier. This includes considering the machine’s efficiency, energy consumption, and the quality of finished products. Some suppliers might offer financing options or warranties to mitigate the initial investment burden, making their equipment more accessible to manufacturers of all sizes.

Moreover, the technological advancement in polishing machines cannot be overlooked. Many suppliers are now incorporating automation and smart features into their machines. These advancements not only improve the efficiency of the polishing process but also enhance precision and reduce the likelihood of human error, resulting in consistent product quality. As manufacturers strive to keep their operations competitive, sourcing from suppliers that offer state-of-the-art technology can be a significant advantage.

In conclusion, the importance of stainless steel square pipe polishing machines in the manufacturing sector cannot be overstated. Suppliers of these machines offer pivotal solutions that improve product quality and operational efficiency. When choosing a supplier, manufacturers must consider machine quality, technical support, cost, and technological advancements. By making informed decisions and partnering with reliable suppliers, manufacturers can ensure they meet the high standards demanded by their industries, thereby enhancing their competitiveness and profitability.