The Advancements in Stainless Steel Polishing Machines

In today's manufacturing landscape, stainless steel is a go-to material for various industries due to its durability, corrosion resistance, and aesthetic appeal. The demand for stainless steel products continues to rise, leading to advancements in the technology and machinery used for processing this essential material. Among these advancements, stainless steel polishing machines play a pivotal role in enhancing the finish and quality of stainless steel items.

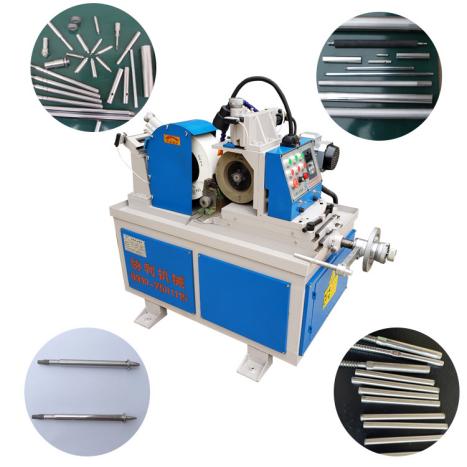

Stainless steel polishing machines are specialized devices designed to refine the surface of stainless steel components, providing a sleek and shiny finish while effectively removing imperfections. These machines cater to a wide range of applications, from manufacturing kitchen appliances and automotive parts to producing decorative elements in architecture and design.

Types of Stainless Steel Polishing Machines

There are several types of stainless steel polishing machines available, each tailored to specific polishing needs. Some of the most common types include

1. Belt Polishers These machines use abrasive belts to smooth the surface of stainless steel products. They are highly efficient for flat surfaces and edges, making them ideal for processing sheets and plates.

2. Rotary Polishers Rotary polishing machines utilize a rotating disc or wheel embedded with polishing compounds to achieve a high-gloss finish. They are perfect for intricate shapes and provide uniform results across different surfaces.

stainless steel polishing machine products

3. Vibratory Polishers Utilizing a vibrating motion, these machines offer a gentle polishing action, making them suitable for delicate and small stainless steel parts. They are particularly effective in deburring and producing a uniform finish on complex shapes.

4. Centrifugal Polishers These machines operate on the principle of centrifugal force, using a combination of media and parts to deliver a polished finish. They are often used for bulk processing of small components.

Benefits of Using Stainless Steel Polishing Machines

Investing in stainless steel polishing machines provides significant benefits. First and foremost, they enhance the aesthetic appeal of products, providing a mirror-like finish that meets customer expectations for quality and design. Furthermore, polished stainless steel surfaces are easier to clean and maintain, reducing corrosion and the buildup of contaminants.

The use of polishing machines also increases efficiency and consistency in production processes. Automation reduces the time and labor required for manual polishing, leading to higher throughput. Additionally, modern polishing machines often come equipped with advanced features such as programmable settings and monitoring systems, ensuring optimal performance and reducing downtime.

Conclusion

The evolution of stainless steel polishing machines reflects the industry's commitment to achieving superior quality and efficiency. As technology continues to advance, manufacturers can expect even greater innovations that will enhance their ability to produce high-quality stainless steel products. From automotive components to architectural fixtures, stainless steel polishing machines are crucial in meeting the demands of various markets, solidifying stainless steel's position as a preferred material in modern manufacturing. Investing in these machines not only elevates product quality but also drives business growth, making them an indispensable asset in today's competitive landscape.