The Role of Stainless Steel Polishing Machine Manufacturers in Modern Industry

Stainless steel polishing machines are critical components in the manufacturing and finishing processes across various industries. These machines not only enhance the aesthetic appeal of stainless steel products but also contribute significantly to their functionality and longevity. As demand for polished stainless steel continues to grow, the role of stainless steel polishing machine manufacturers becomes increasingly important.

The Significance of Polishing in Stainless Steel Production

Polishing stainless steel serves multiple purposes. Primarily, it improves the surface finish, making the material more visually appealing. A polished surface reflects light better, which is essential in industries where aesthetics play a crucial role, such as architecture, automotive, and kitchenware. Additionally, polishing can enhance the corrosion resistance of stainless steel by removing any surface contaminants that could lead to rust or degradation.

Furthermore, a smooth surface can reduce friction and wear, making polished stainless steel ideal for components in machinery and equipment. In sectors like food processing and pharmaceuticals, where hygiene is paramount, polished stainless steel surfaces minimize bacterial growth and facilitate easier cleaning. This highlights the multifaceted advantages that polishing brings to stainless steel, thereby driving the demand for efficient polishing machines.

The Role of Manufacturers

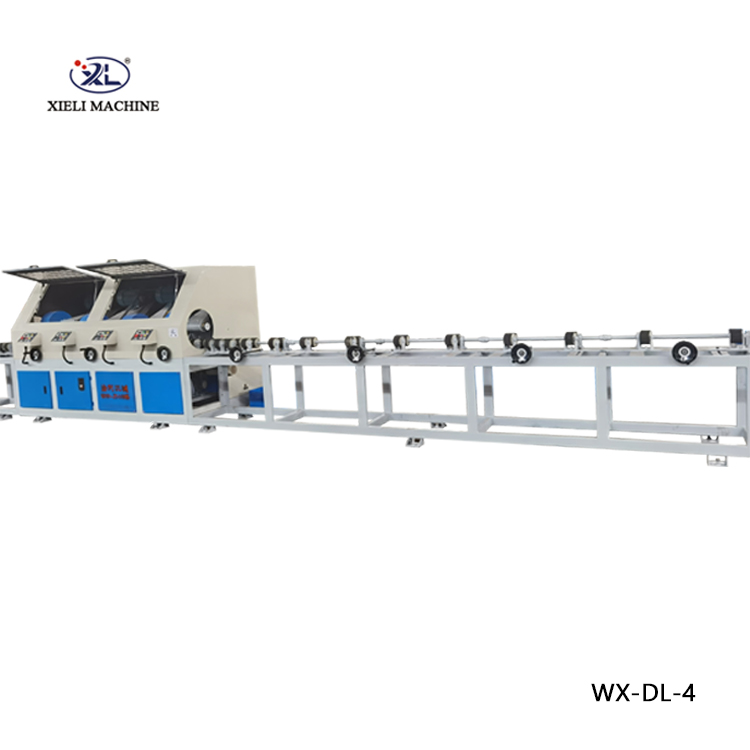

Stainless steel polishing machine manufacturers are vital in meeting this demand. They design and produce machines that cater to various polishing requirements, offering a range of capabilities, from simple handheld tools to automated systems capable of handling large volumes of material. These manufacturers invest in research and development to innovate and refine their products, ensuring that they meet the evolving needs of various industries.

The complexity of polishing processes requires a deep understanding of material science, engineering principles, and production technologies. Leading manufacturers focus on developing machines that are not only highly efficient but also user-friendly. By leveraging cutting-edge technology, such as CNC (Computer Numerical Control) and automation, these manufacturers create machines that deliver consistent results with minimal operator intervention.

stainless steel polishing machine manufacturers company

Environmental Considerations

In today’s environmentally conscious world, stainless steel polishing machine manufacturers are also focusing on sustainability. The polishing process can produce significant waste, including dust and wastewater. Leading manufacturers implement systems to minimize waste production and promote recycling. Furthermore, they are increasingly using eco-friendly materials and chemicals in their processes, aligning with global sustainability goals.

Customer Support and Training

Another important aspect of the role of stainless steel polishing machine manufacturers is customer support and training. Proper operation and maintenance of polishing machines are crucial for achieving optimal results. Manufacturers often provide extensive training programs for operators to ensure they are well-equipped to handle the machinery efficiently and safely.

Additionally, many top manufacturers offer ongoing support and maintenance services to help customers troubleshoot any issues and maintain the machines in peak condition. This support not only enhances customer satisfaction but also extends the lifespan of the equipment, providing better value over time.

Conclusion

In conclusion, stainless steel polishing machine manufacturers play an indispensable role in modern industry. They contribute to the aesthetic and functional enhancement of stainless steel products, ensuring they meet quality standards demanded by different sectors. With a focus on innovation, sustainability, and customer support, these manufacturers are integral to fostering advancements in the processing and finishing of stainless steel. As industries continue to evolve, the importance of these manufacturers will only grow, shaping the future of stainless steel applications and refining the art of polishing.