Stainless Steel Polishing Machine A Key Tool for Excellence in Metal Finishing

In today's manufacturing landscape, the demand for high-quality finishes on stainless steel products is ever-increasing. Whether for kitchen appliances, automotive components, or architectural fixtures, the aesthetic and functional properties of stainless steel are enhanced through effective polishing processes. To meet this demand, stainless steel polishing machines have emerged as an essential tool for manufacturers and exporters seeking to deliver superior products.

The Importance of Stainless Steel Polishing

Stainless steel is lauded for its durability, corrosion resistance, and sleek appearance. However, achieving the perfect finish requires specialized equipment that can efficiently polish surfaces to a high luster. Polishing stainless steel not only improves its appearance but also contributes to its durability by smoothing out imperfections that could lead to corrosion or other forms of damage. As industries evolve, the polishing process has become increasingly sophisticated, requiring advanced machinery that can handle various sizes, shapes, and grades of stainless steel.

Types of Stainless Steel Polishing Machines

Several types of polishing machines are used in the industry, each designed to address specific needs. Some common types include

1. Belt Polishers These machines use a continuous belt coated with abrasive materials to smooth surfaces. They are particularly effective for long, flat pieces of stainless steel, making them popular in the architectural and automotive sectors.

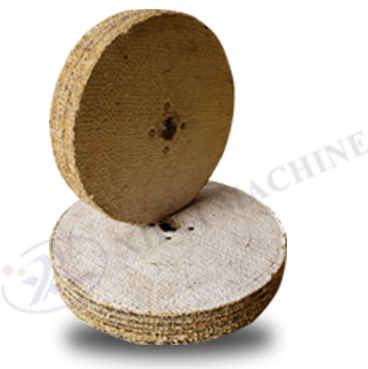

2. Disc Polishers Utilizing rotating discs, these machines can provide detailed polishing for both flat and contoured surfaces. Disc polishers are ideal for small parts and detailed work where precision is paramount.

3. Barrel Polishers These tumbling machines are excellent for mass finishing. By using a combination of water, abrasives, and stainless steel parts, they create a homogeneous finish across multiple items simultaneously, making them a staple for manufacturers dealing with large volumes.

4. CNC Polishers Computer numerical control (CNC) machines offer the highest level of precision. These machines can be programmed to carry out complex polishing patterns and can adapt to different shapes and sizes of stainless steel components, making them a valuable asset in high-tech industries.

Key Features to Look For

stainless steel polishing machine for sale exporter

When considering a stainless steel polishing machine for sale, several factors should be taken into account

- Versatility The ability to polish various grades and forms of stainless steel is crucial. A versatile machine can handle diverse projects without requiring significant adjustments.

- Automation Machines with automated features can enhance productivity by reducing the need for manual intervention. Automation can also lead to more consistent finishes, thereby improving product quality.

- Efficiency Time is of the essence in manufacturing. Choosing a machine that can accomplish polishing tasks quickly without compromising quality can lead to significant operational cost savings.

- Ease of Use A user-friendly interface helps operators work more effectively, particularly for businesses looking to train new employees.

- After-sales Support Having reliable customer support and access to spare parts is essential. Machines are an investment, and a good exporter will provide comprehensive service options.

The Global Market for Stainless Steel Polishing Machines

As the demand for stainless steel products grows globally, so too does the market for polishing machines. Manufacturers are increasingly turning to exporters specializing in stainless steel polishing equipment to enhance their production capabilities. Countries with robust manufacturing sectors, such as China, Germany, and the United States, are key players in this market. Exporters not only provide machines but also offer valuable expertise on optimizing polishing processes, further enhancing product quality.

Conclusion

In conclusion, the stainless steel polishing machine is a critical tool for any manufacturer looking to produce high-quality products. With advances in technology, these machines have become more versatile, efficient, and user-friendly. As businesses strive to meet the demands of an increasingly competitive market, investing in a reliable stainless steel polishing machine can differentiate them from their competition. Whether for aesthetic purposes or enhancing durability, polishing remains a pivotal step in the metal finishing process, shaping the future of stainless steel applications worldwide.