The Evolution of Stainless Steel Plate Polishing Machines A Comprehensive Overview

The industrial landscape has undergone significant transformations over the past few decades, particularly in manufacturing sectors that require high-quality finishes, like the stainless steel industry. A crucial component in achieving optimal quality in stainless steel products is the polishing process. This has led to the emergence and evolution of stainless steel plate polishing machines, with various manufacturers striving to innovate and enhance their offerings to meet the growing demands of the market.

Understanding Stainless Steel Plate Polishing

Stainless steel is renowned for its corrosion resistance, strength, and aesthetic qualities, making it a preferred material in various industries, including automotive, aerospace, and construction. However, the raw finish of stainless steel plates often requires additional treatment to enhance their visual appeal and functionality. Polishing machines are used to meticulously grind, buff, and polish stainless steel surfaces to achieve the desired luminosity and smoothness.

Types of Polishing Machines

Several types of polishing machines are employed in the stainless steel industry, each designed to cater to different aspects of the polishing process

1. Belt Polishers These machines utilize abrasive belts to smoothen the surface of stainless steel plates. They are effective for removing scratches and uneven surfaces, allowing for a consistent finish.

2. Disc Polishers Employing rotating disc pads, these machines are ideal for achieving high-gloss finishes and are often used for final polishing of stainless steel products.

3. Cylindrical Polishers These machines focus on cylindrical surfaces and edges of stainless steel plates, ensuring that even hard-to-reach areas are polished to perfection.

4. Robotic Polishing Systems Advancements in automation have introduced robotic polishing systems that offer precision and reduced labour costs. These systems can operate continuously and maintain consistent quality, significantly improving production efficiency.

Key Manufacturers in the Industry

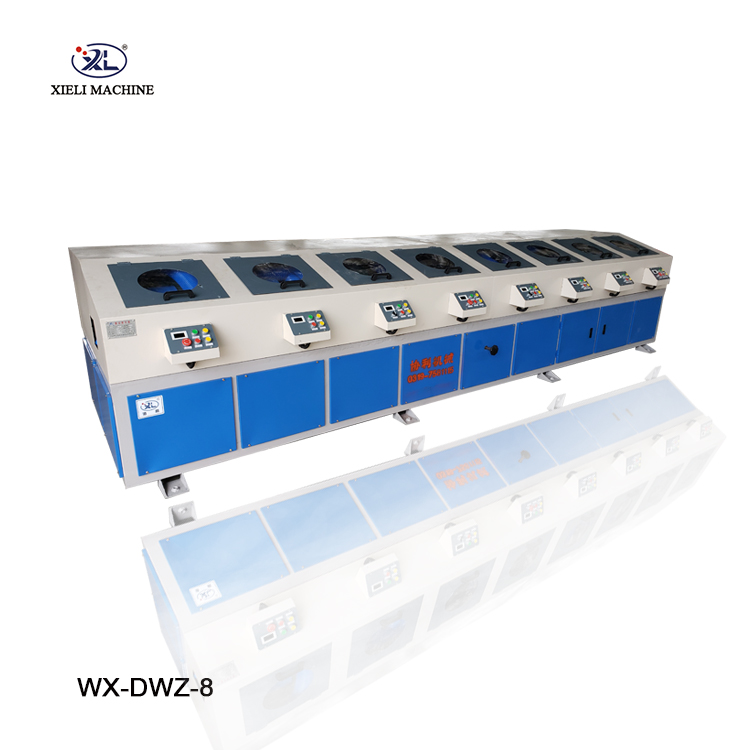

stainless steel plate polishing machine manufacturers

As the demand for stainless steel plate polishing machines rises, numerous manufacturers have emerged, each bringing unique technologies and capabilities to the table. Several key players have made their mark in the industry

- Timesavers, LLC Based in the United States, Timesavers specializes in a vast range of metal finishing equipment, including stainless steel polishing machines. They emphasize quality craftsmanship and innovative design, catering to sectors like metalworking and fabrication.

- Suhner Industrial Products With a strong presence in Europe, Suhner Not only offers polishing machines but also a variety of tools and solutions for surface processing. Their machines are known for their reliability and adaptability to different polishing requirements.

- Kuhlmeyer A leading manufacturer from Germany, Kuhlmeyer focuses on creating highly efficient, robust polishing machines. Their equipment is often noted for integrating advanced control technology, resulting in precise and consistent polishing processes.

- Thompson Machine Known for their bespoke solutions, Thompson Machine offers tailored polishing systems that meet specific client requirements. Their emphasis on customer satisfaction has garnered them a loyal customer base in the stainless steel industry.

Innovations and Future Trends

The stainless steel plate polishing machine market is constantly evolving, driven by innovations in technology and changing customer needs. Recent trends indicate a significant shift towards automation, with more manufacturers adopting robotics and AI-driven solutions to enhance productivity and efficiency. Furthermore, environmentally friendly polishing solutions are gaining traction, with manufacturers exploring sustainable materials and processes that minimize waste and energy consumption.

Additionally, as industries increasingly prioritize quality and aesthetics, the demand for high-precision polishing machines is expected to rise. Companies that invest in research and development to innovate their products will likely lead the market in the coming years.

Conclusion

The role of stainless steel plate polishing machines in the manufacturing sector cannot be overstated. With a growing emphasis on quality, aesthetics, and efficiency, the manufacturers in this space are continually pushing boundaries to meet the evolving demands of the industry. As technology advances and trends shift, the future of stainless steel polishing machinery promises to be exciting, characterized by innovation, precision, and sustainability. Understanding the landscape of stainless steel plate polishing machines and their manufacturers is crucial for businesses looking to thrive in an increasingly competitive marketplace.