The Role of Stainless Steel Plate Polishing Machines in Manufacturing

In the contemporary industrial landscape, the importance of stainless steel plate polishing machines cannot be overstated. These machines play a crucial role in the manufacturing and finishing of stainless steel products, which are widely used across multiple sectors, including construction, automotive, and consumer goods. The automation and precision offered by these machines have transformed traditional polishing methods, making them more efficient and consistent.

Understanding Stainless Steel Plate Polishing

Stainless steel is renowned for its corrosion resistance, durability, and aesthetic appeal. However, achieving a flawless finish on stainless steel plates requires specialized equipment. The polishing process involves the removal of surface imperfections and the enhancement of the material's shine. This is where polishing machines come into play. These machines utilize various techniques such as belt polishing, buffing, and grinding to produce a smooth and reflective surface on stainless steel plates.

Types of Polishing Machines

Stainless steel plate polishing machines come in different types, tailored for specific applications

1. Belt Polishers These machines use abrasive belts to polish stainless steel plates. They are suitable for heavy-duty polishing tasks where significant material removal is necessary.

2. Buffing Machines Buffing machines employ softer materials and compounds to create a high-gloss finish on stainless steel surfaces. These are often used for finishing components that require a mirror-like shine.

3. CNC Polishing Machines Computer Numerical Control (CNC) polishing machines provide high precision and consistency. They can be programmed to follow intricate patterns and specifications, making them ideal for complex designs.

4. Robotic Polishing Systems Automated robotic systems have revolutionized stainless steel polishing by enhancing speed and efficiency. These systems can operate continuously, offering a level of productivity that manual methods cannot achieve.

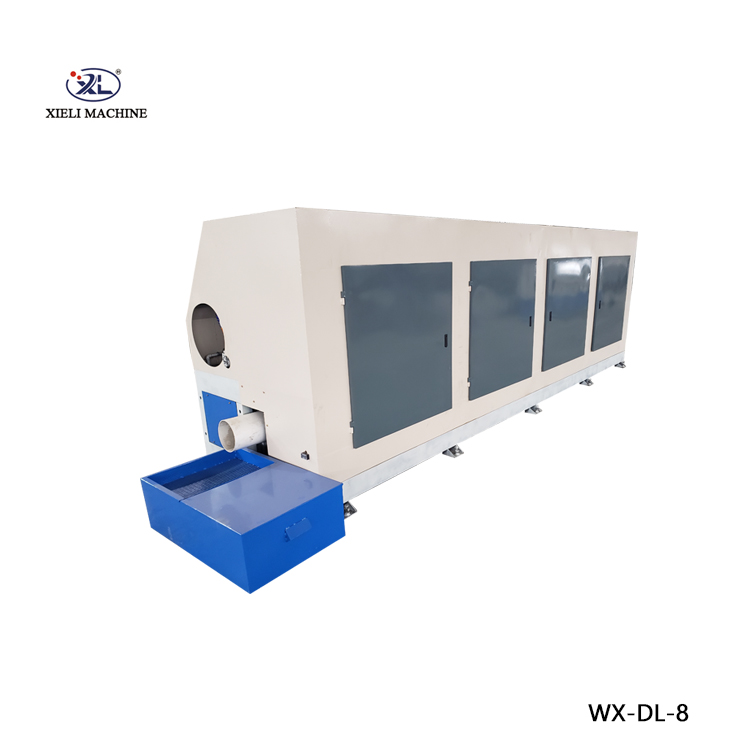

stainless steel plate polishing machine factories

Benefits of Using Polishing Machines

Utilizing stainless steel plate polishing machines offers numerous advantages for manufacturers

- Consistency One of the primary benefits is the uniformity of the finish. Polishing machines ensure that every plate receives the same level of treatment, minimizing inconsistencies that can lead to defects.

- Efficiency Automated machines can process large volumes of materials in a shorter period, significantly increasing production rates. This is essential for manufacturers aiming to meet the growing market demand.

- Cost-Effectiveness While the initial investment in polishing machines may be high, the long-term savings in labor costs, material usage, and time make them a wise investment.

- Safety Machines reduce the need for manual labor, lowering the risk of injuries associated with traditional polishing methods. This leads to a safer working environment.

The Future of Stainless Steel Polishing

As technology continues to evolve, the capabilities of stainless steel plate polishing machines are expected to advance as well. Innovations in artificial intelligence, machine learning, and materials science will likely lead to even more efficient and sophisticated polishing solutions. Additionally, as sustainability becomes a focal point in manufacturing, eco-friendly polishing technologies and materials are also anticipated to emerge.

In conclusion, stainless steel plate polishing machines are indispensable in modern manufacturing. Their ability to deliver high-quality finishes efficiently and consistently not only enhances product aesthetics but also contributes significantly to the operational efficiency of factories. As industries grow and evolve, the role of these machines will be crucial in meeting the increasing demands for polished stainless steel products.