The Importance of Stainless Steel Pipe Polishing Machines A Supplier's Perspective

In the realm of metalworking and fabrication, the quality of finishes is paramount. Among the various materials used, stainless steel stands out for its durability, resistance to corrosion, and aesthetic appeal. However, to fully realize the potential of stainless steel products, especially pipes, polishing is a crucial process. This is where stainless steel pipe polishing machines come into play, serving as an essential tool for manufacturers and suppliers alike.

Understanding the Need for Polishing

Stainless steel pipes are widely used across multiple industries, including construction, automotive, food processing, and pharmaceuticals. While they are known for their robustness, the raw surface of stainless steel pipes can often contain blemishes, scratches, or mill scale left over from the manufacturing process. Polishing not only enhances the visual appeal of these pipes but also improves their resistance to corrosion by removing any impurities.

Achieving a smooth, mirror-like finish is not just about aesthetics; it also plays a significant role in hygiene, particularly in industries such as food processing and pharmaceuticals, where cleanliness is critical. This demand for high-quality finishes has led to the rise of specialized machines designed to polish stainless steel pipes efficiently.

Types of Polishing Machines

When it comes to choosing a stainless steel pipe polishing machine, suppliers offer various types tailored to meet different industrial needs. These include

1. Manual Polishing Machines Ideal for small workshops, these machines require operator skill and are best suited for short runs or custom jobs. They often involve hand-held tools that the operator maneuvers to achieve the desired finish.

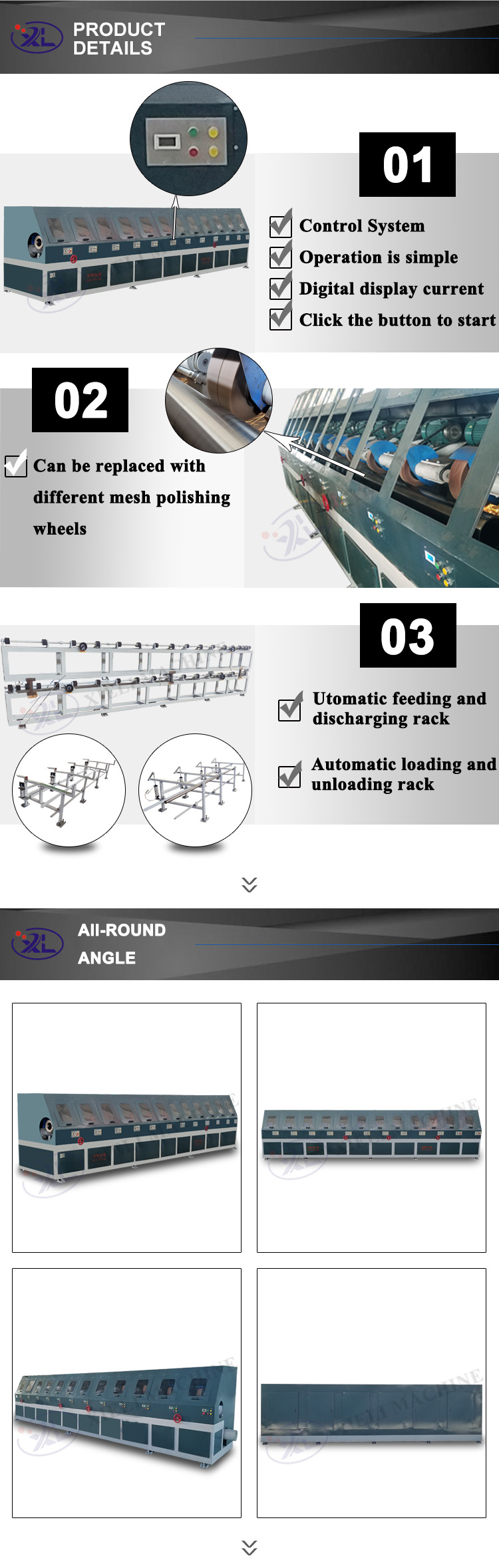

2. Automatic Polishing Machines For larger operations, automatic polishing machines provide high efficiency and consistency. They are designed to handle longer production runs without compromising on quality. Such machines can be programmed to achieve different finishes, from satin to mirror-like surfaces.

3. Robotic Polishing Systems Leveraging automation, robotic systems have revolutionized the polishing process. They offer the benefit of precision and repeatability, making them suitable for high-demand environments. These machines can adapt to various pipe sizes and profiles, enhancing productivity.

stainless steel pipe polishing machine supplier

4. Cylindrical Polishers Specifically designed for polishing the outer surfaces of pipes and tubes, these machines ensure uniform finishes and are essential for industries that prioritize surface aesthetics.

Choosing a Supplier

Selecting the right stainless steel pipe polishing machine supplier is critical for ensuring long-term success. Here are some factors to consider

- Expertise and Experience A supplier with extensive industry experience can provide valuable insights and recommendations tailored to your specific needs. They will understand the nuances of different polishing processes and can suggest the most suitable machinery.

- Quality and Reliability Investing in high-quality machines ensures longevity and consistent performance. Suppliers should be able to provide testimonials or case studies that highlight their machines' reliability.

- After Sales Support A reputable supplier will offer comprehensive after-sales support, including training for operators, maintenance services, and availability of spare parts.

- Customization Options Different industries may require tailored solutions. A good supplier will work with you to customize machines that meet your specific polishing requirements.

Conclusion

In conclusion, stainless steel pipe polishing machines play a crucial role in the manufacturing process, ensuring that the final products meet the high standards expected in today’s competitive market. With the right supplier, companies can not only enhance the aesthetic and functional qualities of stainless steel pipes but also achieve greater efficiency and productivity in their operations. Investing in quality polishing machinery is not just a purchase; it's a commitment to excellence in the metalworking industry.