Stainless Steel Pipe Polishing Machine is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of metal processing machinery. This article explores how Xingtai Xieli Machinery Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Steel Pipe Polishing Machine Overview

- Benefits & Use Cases of Stainless Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Stainless Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

Stainless Steel Pipe Polishing Machine Overview

A Stainless Steel Pipe Polishing Machine—often called a cylindrical polishing machine or stainless steel pipe polisher—is engineered to remove oxide scale, weld discoloration, and surface defects while delivering consistent satin or mirror finishes on round tubes and pipes. In the General equipment manufacturing industry and across the Manufacturing of metal processing machinery segment, this machine is essential for achieving repeatable surface quality, improving corrosion resistance, and meeting stringent appearance standards for downstream assembly.

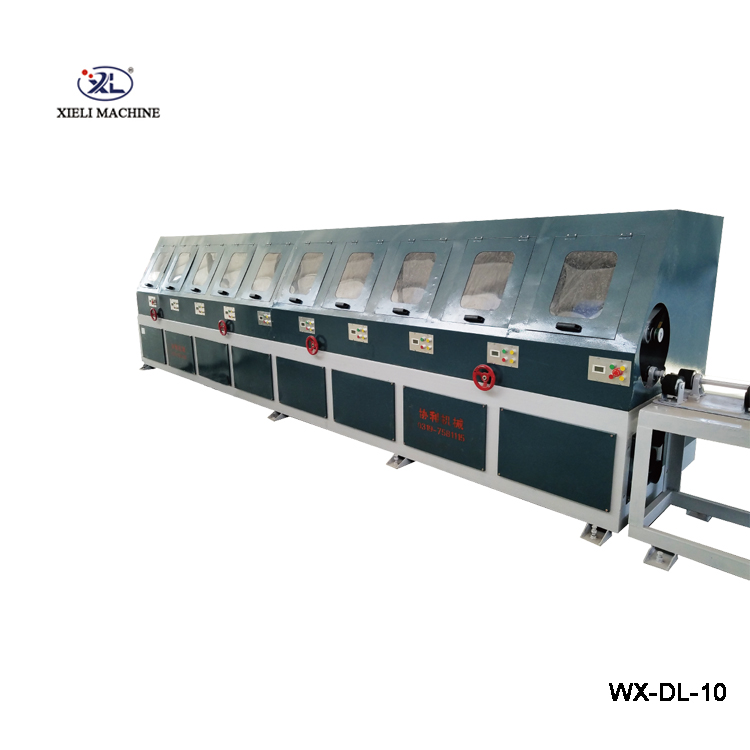

Xingtai Xieli Machinery Manufacturing Co., Ltd. designs through-feed systems that accommodate a wide range of diameters and lengths, with configurable polishing heads to match different finishing goals (from aggressive rust removal to fine finishing). Typical configurations include 2–8 polishing stations, frequency-inverter controlled motors for stable torque, automatic centering rollers, and optional wet/dry modules with integrated dust or coolant management. A PLC/HMI interface allows recipe storage for different materials (304/316) and finish grades, helping operators switch quickly between batches with minimal setup. Customers value the robust frame, belt tracking stability, and efficient abrasive utilization that keeps the process predictable even in high-volume environments.

Benefits & Use Cases of Stainless Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

In metal processing machinery manufacturing, pipe finishing appears at multiple stages: post-weld blending on structural frames, decorative finishing for handrails and equipment guards, descaling on laser-cut tube edges, and precision finishing for heat exchanger tubes and sanitary lines. A stainless steel pipe polisher standardizes these steps, cutting manual labor and reducing variability. With steady through-feed and servo-controlled pressure, operators can maintain target roughness values and finish grades across long runs—ideal for OEMs supplying food, pharma, energy, and construction equipment markets.

Xingtai Xieli’s cylindrical polishing machine platform emphasizes productivity and quality. Quick-change abrasive belts and wheels minimize downtime, while modular head configurations let buyers scale from basic rust removal to multi-stage mirror polishing. Optional wet polishing improves heat control and finish clarity on thin-wall tubes. Advanced safety interlocks, stable workpiece support, and precise belt tracking reduce scratch rates and rework. Backed by Xingtai Xieli Machinery Manufacturing Co., Ltd.’s application know-how, users can align tooling and process parameters with their throughput and finish targets—turning the polishing cell into a reliable, high-yield step in the production line.

Cost, Maintenance & User Experience

Total cost of ownership for a Stainless Steel Pipe Polishing Machine is driven by throughput, abrasive consumption, energy use, and uptime. Xingtai Xieli focuses on durable frames, robust drive systems, and efficient abrasive utilization, helping buyers achieve strong ROI—often through labor savings, higher first-pass yields, and reduced rework. For many B2B operations, automating tubular finishing shifts operators from time-intensive manual grinding to value-added tasks, while maintaining consistent finish quality.

Maintenance is straightforward: daily cleaning of inlets/outlets, periodic belt and wheel changes, and scheduled checks on bearings, coolant filtration (if wet), and dust extraction (if dry). Recipe-driven controls and clear HMI prompts shorten training time and lower the risk of operator error. Feedback from users in the General equipment manufacturing industry highlights stable line speeds, repeatable results across shifts, and high equipment availability when paired with basic preventive maintenance. With responsive parts support from Xingtai Xieli Machinery Manufacturing Co., Ltd., plants keep changeovers and service windows brief, keeping the polishing cell aligned with upstream cutting and downstream welding/assembly takt times.

Sustainability & Market Trends in manufacturing

Manufacturers are moving toward cleaner, safer finishing operations with better dust capture, coolant recirculation, and energy optimization. Stainless steel demand continues to grow in hygienic equipment, clean energy infrastructure, and architectural applications, raising the bar for consistent surface quality. In response, modern polishing systems prioritize enclosure design, airflow control, and wet/dry flexibility while leveraging efficient motors and inverters to match energy use with real production needs. Digital recipe management further reduces scrap, standardizes finishes, and supports faster product changeovers.

Xingtai Xieli Machinery Manufacturing Co., Ltd. aligns with these trends by engineering cylindrical polishing machines that help minimize waste and support safer workplaces. Options for coolant management, dust extraction, and abrasion control are designed to help facilities meet evolving EHS expectations and corporate sustainability goals. As batch sizes shrink and SKU counts rise, Xingtai Xieli’s focus on configurability and smart controls empowers B2B decision makers to future-proof finishing capacity—balancing high throughput with traceable, repeatable surface results.

Conclusion on Stainless Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

For manufacturers in the General equipment manufacturing industry and the Manufacturing of metal processing machinery sector, a Stainless Steel Pipe Polishing Machine is a strategic investment that elevates surface quality, stabilizes throughput, and reduces manual finishing costs. Xingtai Xieli Machinery Manufacturing Co., Ltd. combines robust mechanical design with operator-friendly controls and application support—making its stainless steel pipe polisher platform a reliable, scalable choice for modern production lines.

Ready to improve finish consistency and productivity? Contact us: email: xtjgjc@163.com — Visit our website: https://www.xielizz.com