Stainless Steel Pipe Polishing Machine is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of metal processing machinery. This article explores how Xingtai Xieli Machinery Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Steel Pipe Polishing Machine Overview

- Benefits & Use Cases of Stainless Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Stainless Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

Stainless Steel Pipe Polishing Machine Overview

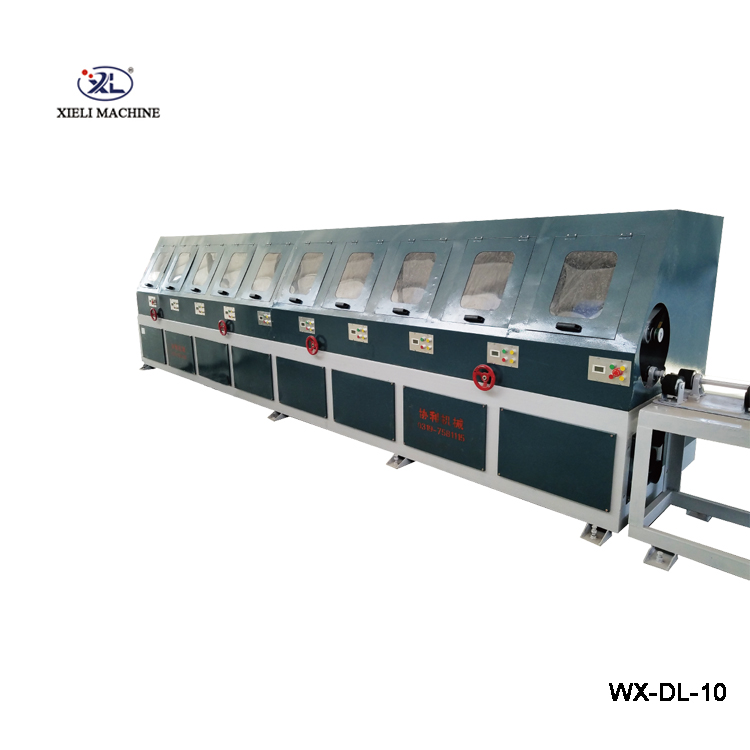

A Stainless Steel Pipe Polishing Machine is engineered to remove rust, oxide layers, weld discoloration, scratches, and surface imperfections from round tubes and pipes, delivering uniform satin, brushed, or mirror finishes. In the General equipment manufacturing industry and the Manufacturing of metal processing machinery sector, consistent surface quality is essential for downstream assembly, welding, and final appearance—especially in applications that demand hygienic or decorative finishes. As a configurable cylindrical polishing machine, it supports a wide range of diameters and lengths with adjustable feed speeds to match production throughput and finish requirements.

Typical systems integrate multi-station abrasive belt heads and buffing wheels, constant-pressure control, and PLC/HMI interfaces for recipe-driven changeovers. Options can include wet or dry processing, dust extraction, automatic belt tracking, and quick-change tooling to minimize downtime. The result is a stainless steel pipe polisher that ensures repeatable Ra values and tight visual standards while reducing manual labor and operator variability. As a reliable manufacturer, Xingtai Xieli Machinery Manufacturing Co., Ltd. focuses on robust frames, stable drives, and practical ergonomics so production teams can run predictable, high-yield finishing lines shift after shift.

Benefits & Use Cases of Stainless Steel Pipe Polishing Machine in Manufacturing of metal processing machinery

Across tube and pipe fabrication lines, this equipment streamlines finishing for architectural handrails, furniture tubing, conveyor rollers, heat exchanger tubes, automotive exhaust components, and food-grade process piping. In machinery manufacturing, uniform OD finishing simplifies gauging, coating, and welding processes while improving the final product’s aesthetics and corrosion resistance. With modular stations, the system can be tailored as a high-throughput cylindrical polishing machine or a compact cell for specialized parts, handling both long stock and short cut lengths with stable guidance and minimal runout.

Competitive advantages include repeatable finish quality, low vibration, and recipe-based setups that reduce operator skill dependency. Variable-speed drives, pressure control, and automatic compensation help maintain consistent contact across diameter variations. Quick abrasive changeovers and integrated safety features support uptime and compliance. As a seasoned stainless steel pipe polisher supplier, Xingtai Xieli Machinery Manufacturing Co., Ltd. brings application know-how—helping teams choose abrasive sequences, wet/dry methods, and dust collection strategies that hit both quality and cost targets.

Cost, Maintenance & User Experience

Total cost of ownership for a Stainless Steel Pipe Polishing Machine depends on energy use, abrasive consumption, throughput, and maintenance practices. Well-engineered drives and optimized contact pressure reduce abrasive waste, while durable bearings and rigid frames extend service life. For B2B decision makers, the ROI often comes from reduced manual finishing labor, fewer rework cycles, and standardized finishes that minimize downstream scrap. When integrated into a flow line, predictable takt times help stabilize scheduling and elevate OEE.

Maintenance is straightforward: routine belt and wheel changes, cleaning of dust extraction or coolant systems, and periodic inspection of tracking and guides. Clear HMI diagnostics and accessible panels shorten service intervals. Customers in the General equipment manufacturing industry value the intuitive setup, recipe storage, and training support provided by Xingtai Xieli Machinery Manufacturing Co., Ltd., noting strong uptime and consistent finish quality. With recommended spares on hand and proactive service guidance, plants keep the machine running efficiently across multi-shift operations.

Sustainability & Market Trends in manufacturing

Market demand is rising for high-quality stainless steel finishes in sectors emphasizing hygiene, durability, and design—driving investment in automated polishing systems. At the same time, manufacturers face stricter environmental, health, and safety expectations around dust, noise, and energy. Modern polishing lines answer with efficient motors, variable-speed controls, robust enclosures, and effective dust extraction or wet-processing options that help meet regulatory requirements while protecting worker health and improving product quality.

Xingtai Xieli Machinery Manufacturing Co., Ltd. adopts a forward-thinking approach: designing equipment to support energy optimization, clean air capture, recyclable consumables where feasible, and longer component lifecycles. Advisory support helps customers select wet/dry modes, filtration, and abrasives that balance sustainability with operational performance. The result is a Stainless Steel Pipe Polishing Machine that aligns with ESG goals, supports compliance, and strengthens competitiveness in an evolving manufacturing landscape.

Conclusion on Stainless Steel Pipe Polishing Machine from Xingtai Xieli Machinery Manufacturing Co., Ltd.

For manufacturers in the General equipment manufacturing industry and the Manufacturing of metal processing machinery, a well-specified Stainless Steel Pipe Polishing Machine delivers consistent finishes, higher throughput, and lower rework—directly improving productivity and customer satisfaction. Backed by Xingtai Xieli Machinery Manufacturing Co., Ltd.’s engineering and application support, your team can standardize finishing quality while simplifying operation and maintenance.

- Contact us: email: xtjgjc@163.com

- Visit our website: https://www.xielizz.com

- Explore the product page: Stainless Steel Pipe Polishing Machine