The Role of SS Pipe Polishing Machine Manufacturers in Modern Industries

In today's manufacturing landscape, the need for high-quality finishes on stainless steel (SS) products is paramount. SS pipe polishing machines have become essential in achieving the required surface quality, ensuring durability and aesthetic appeal. These machines are pivotal in various industries, including automotive, aerospace, pharmaceuticals, and food processing, where stainless steel is frequently utilized for its anti-corrosive properties and strength. The rise of manufacturers specializing in SS pipe polishing machines has greatly enhanced production efficiency and product quality.

Importance of SS Pipe Polishing Machines

Stainless steel pipes often require polishing to remove any imperfections and achieve a uniform, shiny surface. This polishing process is critical as it enhances corrosion resistance, reduces friction, and improves cleanliness, which is particularly important in industries like food processing and pharmaceuticals. The introduction of automated SS pipe polishing machines has revolutionized this aspect of production, allowing companies to achieve consistent finishes while minimizing labor costs and time consumption.

Features of Modern SS Pipe Polishing Machines

Today's SS pipe polishing machines are equipped with advanced features that cater to the diverse needs of manufacturers. Many of these machines utilize multiple stages of polishing, which can include processes like grinding, buffing, and passivation. This multi-step approach ensures a superior finish that meets stringent industry standards. Additionally, modern machines often incorporate programmable logic controllers (PLCs) and touch-screen interfaces, allowing operators to customize processes easily and monitor quality metrics in real-time.

Efficient dust extraction and waste management systems are also integral features of current SS pipe polishing machines. These systems not only improve the working environment by minimizing air pollution and potential hazards but also contribute to sustainable practices by ensuring that waste material is managed responsibly. With growing industry emphasis on sustainability, manufacturers of polishing machines are increasingly focusing on eco-friendly designs and operations.

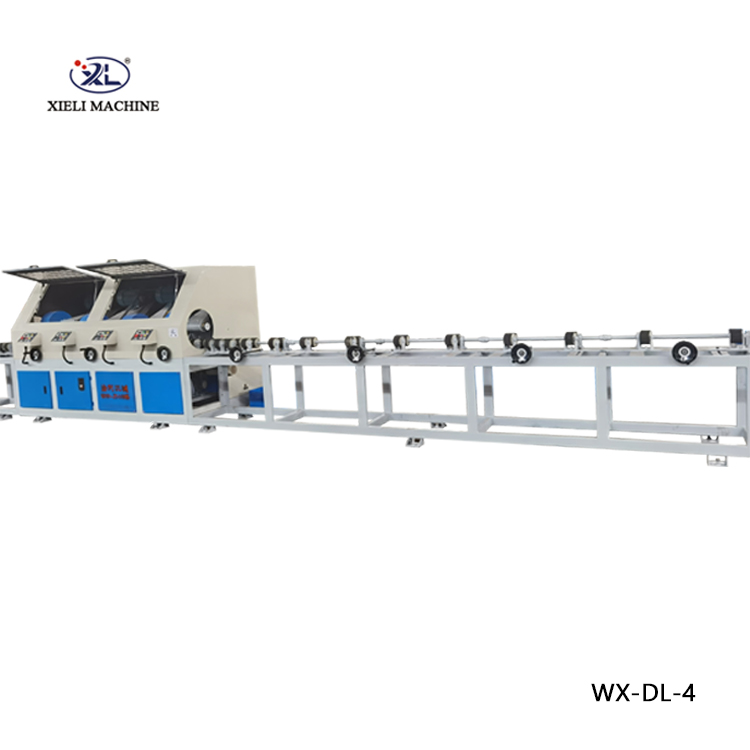

ss pipe polishing machine manufacturer manufacturer

Customization and Versatility

Manufacturers of SS pipe polishing machines understand that different industries have unique requirements. As such, they often provide customization options to cater to specific client needs. This can include varying the machine size, polishing speed, and the type of materials processed. Additionally, some advanced models can handle different pipe diameters and thicknesses, making them versatile for diverse applications.

Market Trends and Future Outlook

The demand for SS pipe polishing machines is expected to grow in the coming years, driven by the expanding stainless steel market and increasing industrial automation. As companies seek to optimize their manufacturing processes, the integration of artificial intelligence (AI) and machine learning techniques into polishing machines may become more prevalent. These technologies can help in predictive maintenance, reducing downtime, and enhancing the overall efficiency of operations.

Moreover, manufacturers are likely to continue emphasizing eco-friendly practices, ensuring that their machines not only meet the operational needs of industries but also contribute to sustainable manufacturing standards.

Conclusion

The role of SS pipe polishing machine manufacturers is crucial in fostering quality and efficiency in manufacturing processes. As technology continues to evolve, these manufacturers are at the forefront, providing innovative solutions that meet the demands of various industries. With ongoing advancements and a focus on sustainability, the future of SS pipe polishing appears bright, promising enhanced capabilities and an unwavering commitment to quality.