The Evolution and Importance of Square Tube Grinding Machine Manufacturers

In the realm of manufacturing, precision and quality are key components to ensuring the success of any production line, particularly in fields that require metal fabrication and processing. One vital tool that has significantly influenced these operations is the square tube grinding machine. This specialized equipment allows manufacturers to achieve smooth, precise finishes on square tubes, which are commonly used in various industries ranging from construction to automotive components. As a result, companies producing square tube grinding machines have become essential players in the contemporary industrial landscape.

Understanding Square Tube Grinding Machines

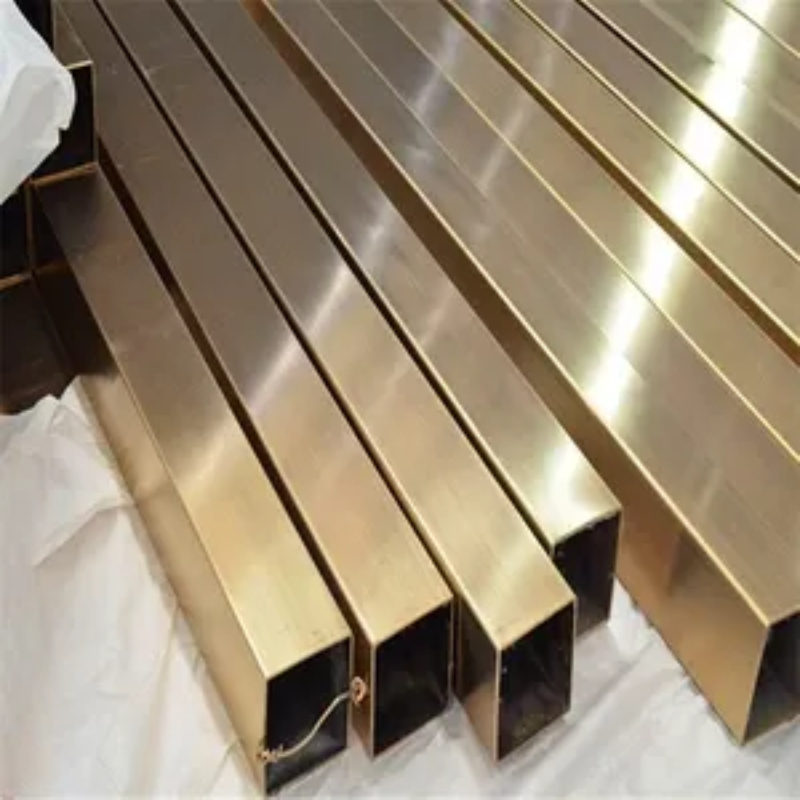

Square tube grinding machines are designed for the effective processing of square cross-section tubes. Unlike traditional grinding machines, which may not be optimized for the specific geometries of square tubes, these machines utilize advanced technologies and tailored machinery to deliver superior results. They often feature multiple grinding heads, allowing operators to perform various tasks such as surface grinding, edge grinding, and deburring—all in a single pass. This level of efficiency saves both time and resources, making these machines invaluable in high-output environments.

The Market Demand for Grinding Machines

The demand for square tube grinding machines has risen significantly in recent years. As industries strive for efficiency and precision, the need for dependable machinery that can deliver consistent results has never been greater. Square tubes are widely used in the construction sector for structural support systems, machinery frames, furniture making, and more. The finishing processes these tubes undergo often require intricate grinding to achieve the desired level of smoothness and design specifications.

Consequently, square tube grinding machine manufacturers have adapted to meet the growing demands of the market. By integrating automation and advanced control technologies, these companies have developed machines that reduce operator fatigue while increasing productivity and quality. The trend towards Industry 4.0—characterized by the interconnectivity of smart machines and data analytics—further amplifies the role of grinding machines. Manufacturers are increasingly investing in R&D to develop machines that can seamlessly integrate with modern production lines.

square tube grinding machine companies

Key Players in the Industry

Several companies have emerged as leaders in the square tube grinding machine sector. Established manufacturers such as Biesse Group, KELLER, and M.Z. Maschinenbau have built reputations for producing high-quality, reliable machines. They focus on continuous innovation, offering machines that employ CNC (Computer Numerical Control) technology, which allows for precise operation with minimal human intervention. Furthermore, these companies emphasize customer support and after-sales services, recognizing that the success of their machines in a customer's facility depends on effective maintenance and operation training.

Smaller niche players also contribute significantly to the industry by offering customized solutions tailored to specific customer needs. These companies may provide more flexible manufacturing options that allow clients to tackle unique projects that larger manufacturers might overlook. As a result, many clients opt to work with a diverse range of manufacturers to ensure they acquire a machine perfectly suited to their operation's specific requirements.

Future Trends and Innovations

Looking ahead, the square tube grinding machine market is poised for further innovations driven by advancements in technology. The integration of AI and machine learning is expected to enhance machine capabilities, allowing for real-time adjustments based on production conditions. Additionally, enhanced ergonomic designs will likely improve operator comfort and safety, a critical consideration in today's manufacturing environments.

Sustainability is another critical consideration shaping the future of manufacturing. Companies are increasingly focusing on energy-efficient machines and processes that minimize waste, addressing both environmental concerns and cost-saving measures for businesses. As sustainability becomes a central theme across industries, manufacturers of grinding machines must adapt to these evolving standards.

In conclusion, square tube grinding machine manufacturers play a vital role in the success of many industries reliant on metal fabrication. Their innovations not only drive efficiency but also enhance the quality of finished products, contributing to a more competitive manufacturing landscape. As technology continues to advance, the future of these machines looks bright, promising even greater precision and sustainability solutions.